BASIC OPERATION AND FEATURES

SX TRANSISTOR CONTROL Page 7

January 2000

to optimize motor and control performance, and this setting

will be determined by GE and OEM engineers at the time of

vehicle development. This setting must not be changed by

field personnel, without the permission of the OEM.

Section 2.1.4.b Speed Limits

This feature provides a means to control speed by limiting

motor volts utilizing three "adjustable speed limits. This

motor volt limit regulates top speed of the transistor

controller, but actual truck speed will vary at any set point

depending on the loading of the vehicle. Each speed limit

can be adjustable with the Handset using Functions 11, 12,

and 13.

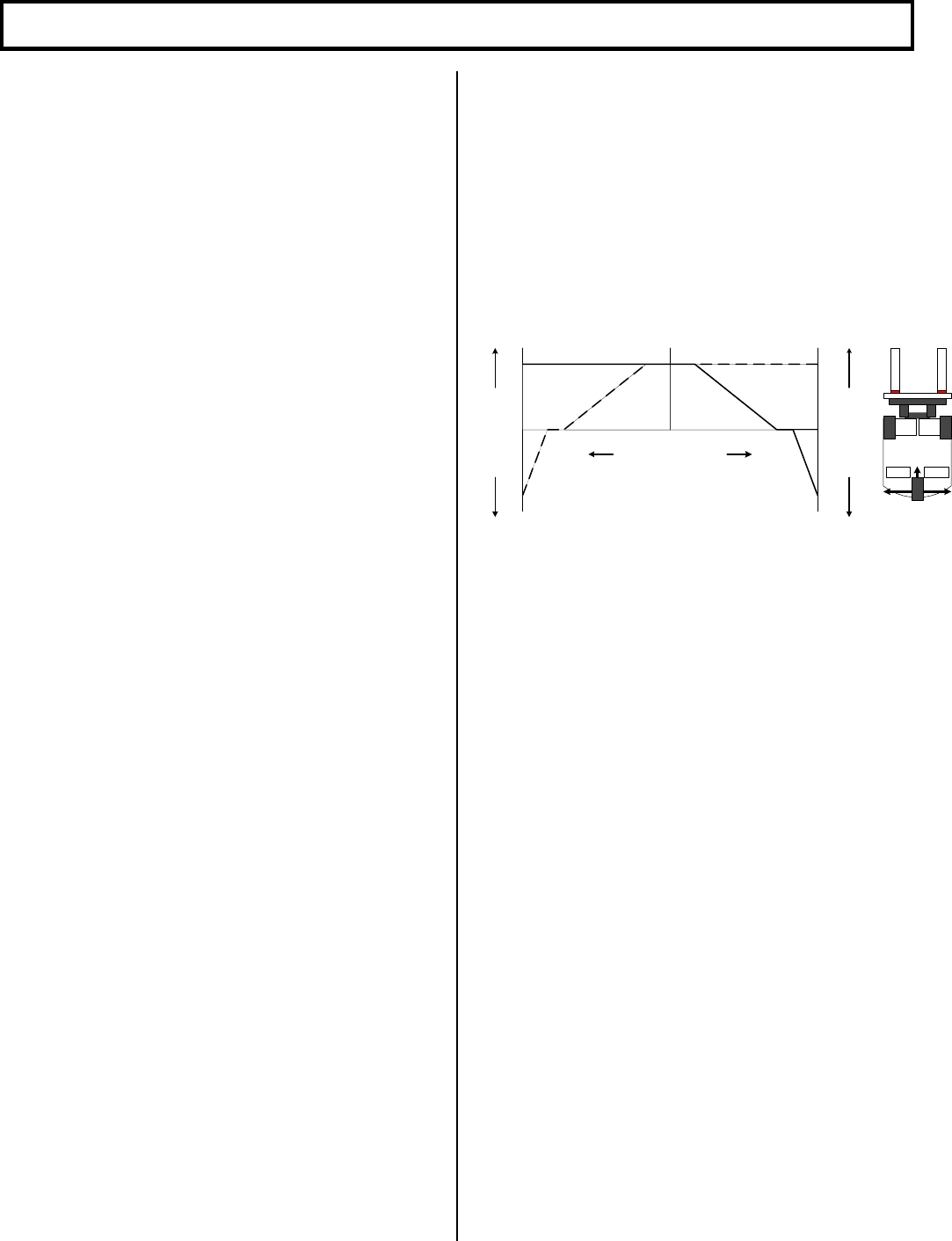

Section 2.1.4.c Proportional Operation for Dual Motor

Vehicles

A key performance advantage of this control is the ability to

achieve actual "proportioning" of motor speed. In a

non-proportioning, or single control, system when the

vehicle starts to turn, the outside drive wheel turns in a

larger circle than the inside wheel. Depending on the

geometry of the vehicle, at some degree of turn angle, the

inside wheel must slow down to prevent scrubbing of the

wheel. This is accomplished on single control system by

disconnecting the inside motor and letting the wheel "free

wheel" or "float" at whatever speed is dictated by the

outside wheel that is still under power. The main

disadvantage of this system is that no torque is available on

that motor when the inside wheel is in the "free-wheel"

mode, and performance in a turn is reduced. When the

steer wheel nears to the 90° turn angle, the inside motor is

re-connected in the opposite direction of the outside. At

this point, torque is returned to the inside wheel and the

speed is the same on both motors.

With two controls, the speed of each motor can be

regulated independently. The driver controls the speed of

the outside wheel with the accelerator input signal. The

inside wheel speed is controlled by the turn angle of the

steer wheel . A potentiometer is attached to the steer wheel

in order to communicate the steer angle to the controllers.

During vehicle manufacture, software selection identifies

each control for its application as a right or left control.

The controls are physically identical, and it is only software

that separates a right from a left control or differentiates a

control for a dual motor application from one intended for a

single motor vehicle. As the steer reaches some

pre-selected turn angle, approximately 20

o

, the speed of the

inside wheel decrease proportionally to the speed of the

outside wheel. This proportional decline will continue on a

linear path until the steer angle reaches another pre-

determine angle of, approximately 65

o

.

At this point, the inside wheel will stop, as the steer angle is

increased toward the 90° point, the inside wheel will

reverse direction and start to accelerate proportionally in

speed. As the steer angle reaches the 90° point, the inside

wheel speed will be the same as that of the outside wheel.

During this entire turn, except for several degrees when the

motor was stopped to change direction, torque was always

present on the inside wheel, providing a smoother ride

throughout the turning radius of the vehicle.

Details for adjustment of the steer angle potentiometer can

be found in Appendix A of this manual.

0

O

10

O

10

O

20

O

20

O

30

O

30

O

40

O

40

O

50

O

50

O

60

O

60

O

70

O

70

O

80

O

80

O

90

O

100%

50%

50%

100%

90

O

100%

50%

50%

100%

RIGHT

MOTOR

LEFT

MOTOR

STEERING ANGLE

LEFT

TURN

RIGHT

TURN

LEFT

MOTOR

RIGHT

MOTOR

RIGHT

CONTROL

LEFT

CONTROL

0

O

90

O

90

O

REV - SPEED - FWD

REV - SPEED - FWD

Section 2.1.5 Ramp Operation

Section 2.1.5a Ramp Start

This feature provides maximum control torque to restart a

vehicle on an incline. The memory for this function is the

directional switch. When stopping on an incline, the

directional switch must be left in its original or neutral

position to allow the control to initiate full power when

restarted. The accelerator potentiometer input will

modulate ramp start current.

Section 2.1.5b Anti-Rollback

This feature provides retarding torque to limit rollback

speed in the non-travel direction when the ACC pedal is

released when stopping on a grade, or when the brake

pedal is released when starting on a grade. This feature

forces the vehicle to roll very slowly down the grade when

accelerator or brake is released. Because the vehicle can

gain significant speed during roll-back, the torque needed

to re-start on the ramp is lower than an unrestricted roll-

back speed.

Section 2.1.6 Steer Pump Contactor Time Delay

This feature provides two options for SP time delay. Option

1 provides a 0.5 to 63 second time delayed drop out of the

steer pump contactor when the Forward or Reverse

directional switch is opened. This Option 1 is overridden by

a 1.5 second time delayed drop out whenever the seat

switch is opened. Option 2 provides a 0.5 to 63 second time

delayed drop out of the SP contactor when the seat switch

is opened.