I. The machine may stop working if the condenser temperature exceeds the pre-set temperature of the Over Temperature Thermostat (non-

adjustable) due to a very high ambient temperature, condenser fan failure, dirty/ blocked condenser. To restart the machine, depress the

protruding button on the Alarm Reset.

J. Changes to the defrost time. Under normal circumstances no adjustments should be necessary.

The fixed time can be adjusted by releasing the tension on the cam screw, turning the dial anti-clockwise to increase the defrost time and

clockwise to decrease the defrost time, retighten the screw when the adjustment has been completed.

Note. If adjustment are made it will effect the freeze cycle.

Increasing the defrost time will shorten the freeze time so adjustments to the cube size thermostat may need to be made to increase

the freeze temperature.

Decreasing the defrost time will increase the freeze time so adjustments to the cube size thermostat may need to be made to decrease

the freeze temperature.

3.4 Cleaning/Rinsing For F20, 40, 60, 85

A. Remove the bottom front panel and locate the changeover switch.

B. Remove the top cover to gain access to the evaporator.

D. Wait till the machine finishes its freeze cycle and then turn off the electrical supply to the machine.

D. Prepare the cleaning solution as per the manufactures instructions on the Ice Machine Cleaner.

Warning. The Ice Machine Cleaner contains Phosphoric and Hydroxyacetic acids. These compounds are corrosive and may cause burns if

swallowed. If swallowed DO NOT induce vomiting, drink lots of water or milk and contact your Doctor immediately.

In case of external contact wash off with clean water.

E. Scoop out all of the ice cubes stored in the bin in order to prevent them from being contaminated by the cleaning solution then drain the water

from the sump reservoir by removing the plastic overflow pipe. Once the water has drained from the sump replace the pipe.

F. Remove the evaporator cover and slowly pour the solution onto the evaporator platen. Use a soft brush if necessary to remove stubborn

deposits.

G. Press the switch to the clean position and restore the electrical supply to the machine.

H. Leave the machine in the cleaning/rinsing mode for at least twenty minutes then turn the machine off at the electrical supply to the machine.

It may be necessary to clean the water spray separately. If required remove the spray plate from the machine, mix a solution of the cleaner in

a bowl or bucket and immerse the plate in it. When clean thoroughly rinse with clean water and re-fit it into the machine.

I. Drain the cleaning solution from the sump reservoir by removing the plastic overflow pipe. Once the solution has drained from the sump replace

the pipe.

J. Pour two to three litres of clean water over the evaporator platen to rinse of the remaining solution and ensure sufficient water is in the reservoir.

Ensure that the switch is still in the ‘CLEAN’ position and turn on the electrical supply to the machine. Leave the machine in the cleaning mode

for at least five minutes to thoroughly rinse the entire water system.

K. Drain the rinsing water from the sump reservoir by removing the plastic overflow pipe. Once the rinsing water has drained from the sump replace

the pipe and thoroughly wipe the interior of the machine.

L. Replace the evaporator cover and top service panel, turn on the electrical supply to the machine with the switch still in the wash position.

Leave the switch in this position for approximately five minutes to allow the water reservoir to fill up.

M. Change the switch setting to the freeze position to start the freeze process.

N. At the completion of the freezing and harvest cycle make sure the ice cubes are the proper texture and do not have an acid taste.

Attention. If the ice cubes are cloudy-white and have an acid taste, discard them immediately by pouring warm water over them to prevent them

from being used.

O. Once you are satisfied that all of the cleaning solution has been removed from the machine rinse the storage bin with clean water and wipe

clean.

Remember. To prevent the accumulation of undesirable bacteria it is necessary to sanitize the interior of the storage bin with an anti-

algae solution each week.

6

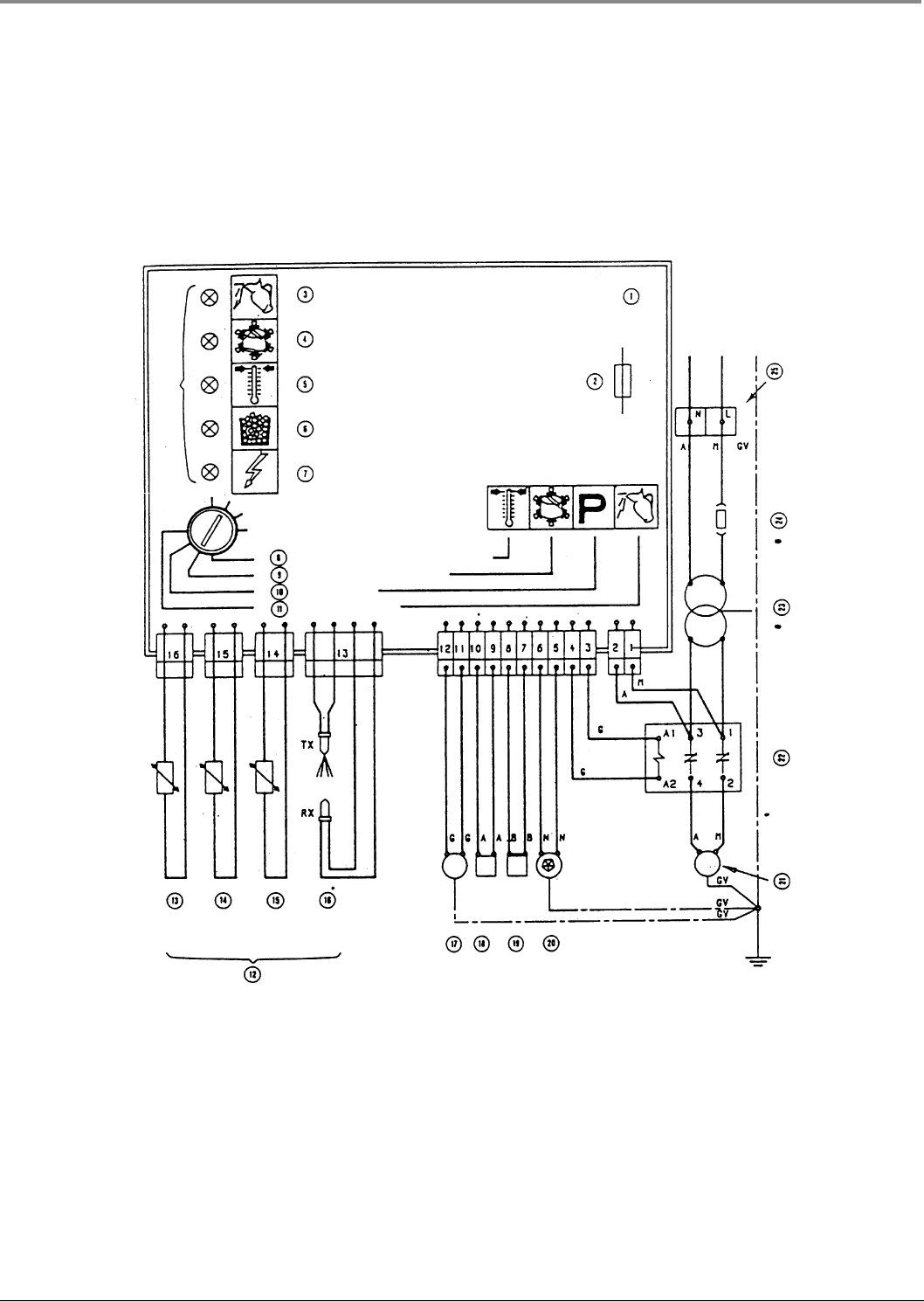

14. Wiring Diagram

WIRING DIAGRAM - SCHEMA ELETTRICO

SCHÉMA ÉLECTRIQUE - SCHALTUNGSCHEMA

AIR & WATER COOLED - RAFFREDDAMENTO AD ARIA ED AD ACQUA.

REFROIDISSEMENT A AIR ET A EAU - LUFT UND WASSERGEKÜHLT

220-240/50/1

(1) Printed Circuit Board

(2) Fuse

(3) Rinsing

(4) Freezing Oper.

(5) Too High Temperature

(6) Bin Full

(7) Power On

(8) Reset to High Temp.

(9) Freezing Oper.

(19) Water Inlet Valve

(20) Fan Motor

(21) Compressor

(22) Contactor

(23) Autotransformer

(24) Fuse

(25) Terminal Board

(10) Stand By

(11) Rinsing

(12) Sensors

(13) Evaporator Temperature

(14) Condenser Temperature

(15) Ambient Temp.

(16) Ice Level Sensor

(17) Water Pump

(18) Hot Gas Valve

* USED ONLY UNIT 240V JUST FOR AIR COOLED UNIT

19