2. F20 and F40 Technical Data and Operating Instructions

2.1 Technical Data

Model F20 F40

Output – kg/24hr 19.5 34.5

Bin storage capacity – kg 6.5 15

Cubes per cycle 16 24

Cubes kg per cycle 0.28 0.42

Cycle time – minutes 20.7 17.5

Amps start/run 11Amps/2Amps 17Amps/3.3Amps

Watts consumption (30°C Ambient Temp) 320w 450w

Water consumption (Water Temp at 15°C Ambient Temp 21°C) 8.5 8.5

Refrigerant R134A R134A

Refrigerant charge grams 250 grms 320 grms

Evaporator Temp with Gas Pressure at 10.5 Bar ( Ambient Temp 21°C) -7°C -9°C

Evaporator Temp with Gas Pressure at 7.5 Bar ( Ambient Temp 21°C) -27°C -24°C

Evaporator Temp with Gas Pressure at 13 Bar ( Ambient Temp 32°C) -5°C -6°C

Evaporator Temp with Gas Pressure at 8 Bar ( Ambient Temp 32°C) -26°C -24°C

Heat Emission, watts 540 850

Noise Level dBA at 2 meters 55dBA 58 dBA

2.2 Start Up

After having correctly installed the ice machine and completed the plumbing and electrical connections, perform the following “Start-up”

procedure.

A Switch on the power to the machine. The unit starts its first freezing cycle with the following components in operation:

COMPRESSOR

WATER PUMP

FAN MOTOR. (The condenser fan is controlled by a thermostat, factory set at approximately 33°C).

B Check through the ice discharge opening that the spray plate is correctly seated and that the water jets uniformly reach the interior of the inverted

cup molds; also make sure that the plastic curtain is hanging freely and that water is not spilling through it excessively.

C The ice making process takes place thereby, the water is sprayed into the molds which gets gradually refrigerated by the heat exchanged with

the refrigerant flowing into the evaporator serpentine.

D When the evaporator temperature reaches a pre-set value the evaporator thermostat changes its contacts, the freezing cycle ends and the

defrost/harvest cycle starts.

Freezing time will range between 17 and 22 minutes (depending on model, see table) in a 21°C ambient. Longer time for temperature above,

shorter when below.

Average complete cycle range is about 17 to 25 minutes (depending on model, see table above)

E Check, during the first defrost/harvest cycle, that the incoming water flows correctly into the sump reservoir in order to re-fill it and the surplus

overflows down the overflow drain tube.

During this cycle the components energised are:

COMPRESSOR.

HOT GAS SOLENOID.

WATER INLET SOLENOID VALVE.

The FAN MOTOR and the WATER PUMP are also in operation if ambient temperature exceeds 33°C.

Note. During the defrost cycle, the water inlet solenoid valve is energised. The water flows through the valve to the back of the

evaporator platen and then down to fill up the icemaker sump tank for the next freezing cycle.

F Check the texture of the ice cubes just released. The correct size has a small depression (about 5-6mm) in their crown. If not, wait for the second

defrost/harvest cycle before making any adjustments.

2.3 Adjustments

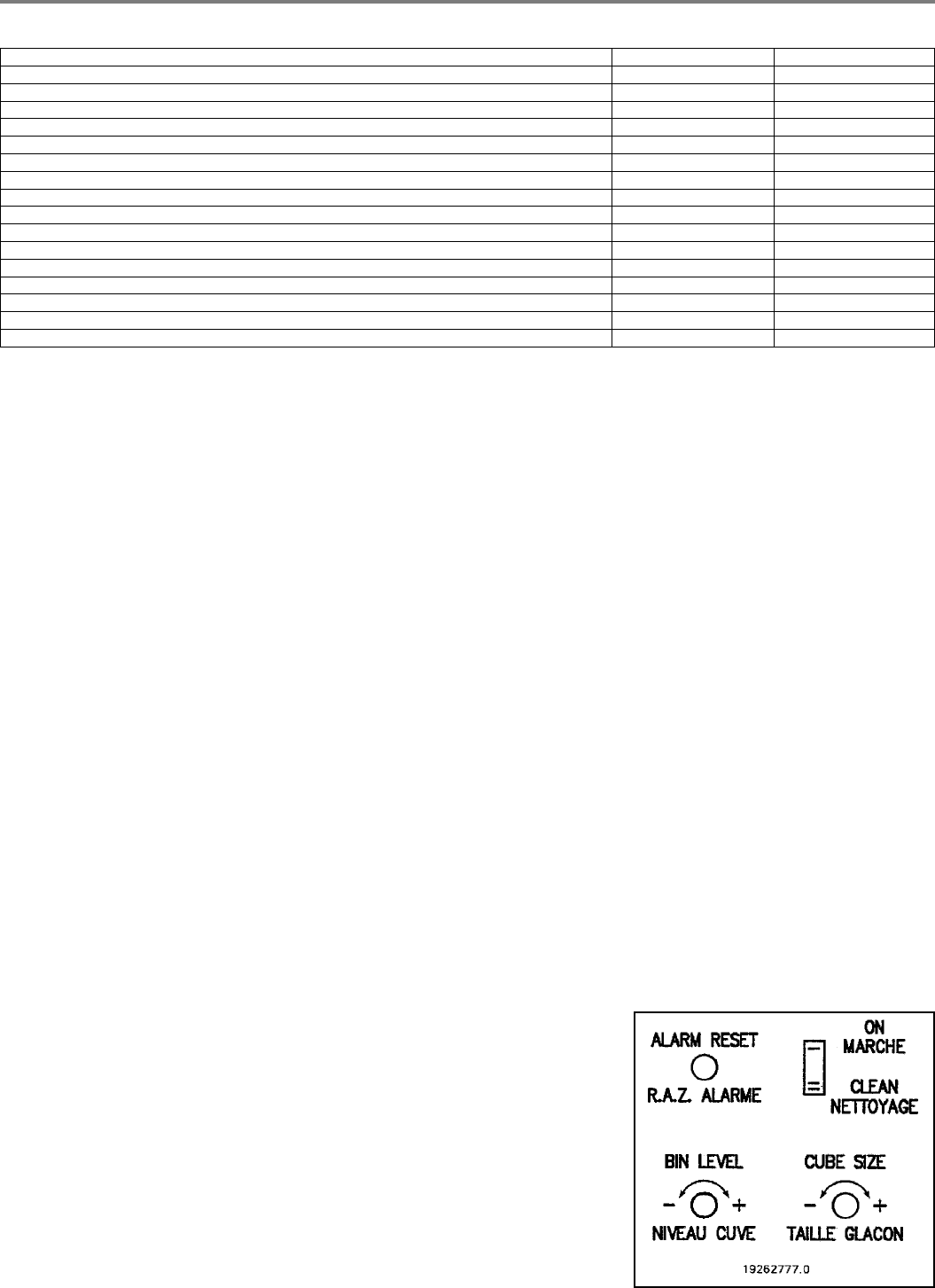

G If after the second harvest the cubes are not correct adjustment to the evaporator thermostat may be necessary.

Remove the front panel and locate the cube size thermostat, using a flat bladed screwdriver turn towards the ‘+’ to increase the cube size and

towards the ‘-’ to decrease the cube size. (See fig 1)

H To check the bin full thermostat hold a handful of ice against the bulb of the storage bin

thermostat, the ice maker will switch off in about one to two minutes.

Once the machine has stopped remove the ice and dispose of it, the machine will restart

automatically in three to four minutes.

Note. The bin thermostat is factory set at 1°C (35°F) CUT OUT and 4°C (39°F) CUT IN.

(The set temperature can be adjusted if required by using a flat bladed screwdriver

turn towards the ‘+’ to increase the bin temperature and towards the ‘-’ to decrease

the bin temperature). (See fig 1)

Refit the bottom front panel then instruct the owner/user on the general operation of the

machine and about the cleaning and care it requires.

I. The machine may stop working if the condenser temperature exceeds the pre-set temperature

of the Over Temperature Thermostat (non-adjustable) due to a very high ambient temperature,

condenser fan failure, dirty/ blocked condenser. To restart the machine depresses the

protruding button on the Alarm Reset.

Fig. 1

4

16. Maintenance and Cleaning Instructions

16.1 General

The periods and the procedures for maintenance and cleaning are given as guides and are not to be construed as absolute or invariable.

Cleaning, especially, will vary depending upon local water and ambient conditions and the ice volume produced; and, each ice maker must be

maintained individually, in accordance with its particular. location requirements.

16.2 Icemaker

The following maintenance should be scheduled at least twice per year on these ice makers.

1. Check and clean the water line strainer.

2. Check that the ice maker is levelled side to side and in front to rear directions.

3. Clean the water system, the evaporator, the bin and spray platen using a solution of Ice Machine Cleaner.

Refer to procedure 15.3 cleaning instructions and after cleaning will indicate frequency and procedure to be followed in local areas.

NOTE Cleaning requirements vary according to the local water conditions and

individual user operation. Continuous check of the clarity of ice cubes and visual

inspection of the water spraying parts before and after cleaning will indicate

frequency and procedure to be followed in local areas.

4. With the ice machine and fan motor OFF on air cooled models, clean condenser using vacuum cleaner, soft brush or non metallic brush.

5. Check for water leaks and tighten drain line connections. Pour water down bin drain line to be sure that drain line is open and clear.

6. Check size, condition and texture of ice cubes. Perform adjustment of DIP SWITCH

keys as required.

7. Check the ice level control sensor to test shut-off.

Put a shovelful of ice cubes in contact with the control sensor during the defrost cycle.

This should cause the ice maker to shut off at the end of the defrost cycle and the light up the 3rd RED LED.

Within a few seconds after the removal of the shovelful of ice from the sensing probe, the ice maker restarts in freezing cycle.

NOTE The RANGE OF THE ICE LEVEL CONTROL SENSOR can be adjusted as shown on table D of PRINCIPLE OF OPERATION; its cut

out setting remains however at +2˚C (35˚F).

8. Check for refrigerant leaks.

16.3 Cleaning Instructions of Water System

1. Remove the rear and top panels to gain access either to the control box or to the evaporator.

2. Wait till the end of defrost cycle then, with the help of a normal screwdriver, turn the program selector head on STAND BY position to

temporarily stop the operation (Fig. 10). + (Fig. 8) (R134A Machines Fig. 7).

Fig. 10

3. Prepare the cleaning solution by diluting in a plastic container one or two litres of warm water (45-50˚C) with 0.1-0.2 litres of Ice Machine

Cleaner.

WARNING The Ice Machine Cleaner contain: Phosphoric and Hydroxyacetic acids.

These compound: are corrosive and may cause bums if swallowed, DO NOT induce vomiting. Give large amount: of water or milk. Call Physician

Immediately.

In case of external contact flush with water.

KEEP OUT OF THE REACH OF CHILDREN.

4. Scoop out all the ice cubes stored into the bin in order to prevent them from being contaminated with the cleaning solution then flush out

the

water from the sump reservoir by removing the plastic plug.

5. Remove the evaporator cover then slowly pour onto the evaporator platen the cleaning solution. With the help of a brush dissolve the

most

resistant and remote scale deposits in the platen.

6. Set the program selector head on CLEANING/RINSING (Fig. 11) + (Fig. 9).

21