6 307400

Operation

Start-up

The mixer manifold was tested in oil, which was left in

to protect the manifold. Before operating, thoroughly

flush the manifold to prevent contamination of the

fluids.

Flushing Procedure

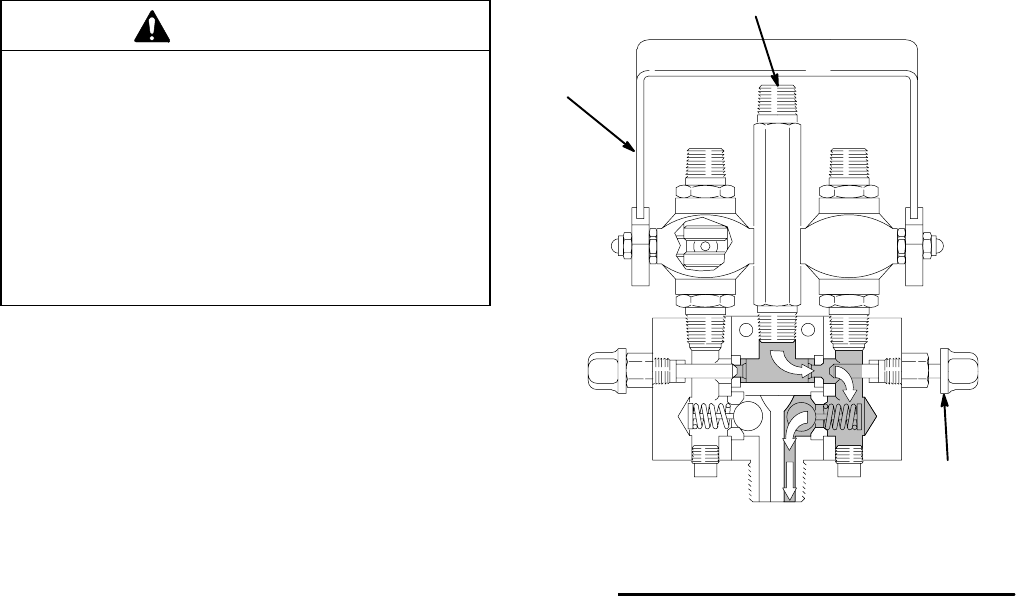

CAUTION

Be sure to label all fluid path parts “component A” or

“component B” when disassembling them. Doing so

prevents interchanging A and B parts during reas-

sembly, which will contaminate the materials and the

fluid path through the equipment.

Color-coded chemically resistant tape may be used

to label the parts. Use blue for component A, green

for component B, white for solvent, and red for mixed

material.

Place the handle in the UP, or closed, position. Turn on

the solvent supply pump. Open one of the solvent

valves. Release the spray gun safety latch. Hold the

gun firmly to the side of a grounded metal pail, then

trigger the gun to flush. Flush until all contaminants

and oil are removed. Release the trigger, engage the

safety latch, and close the solvent valve. Repeat for

the other solvent valve.

Any ratio check valves on the manifold output side

must be flushed. Place a container under both valves

to catch the waste solvent. Flush the valves after trig-

gering the gun, one side at a time.

Solvent may channel through viscous fluids and leave

a coating of mixed fluid on the inner tube of your hose.

Fig 2 shows the handle in the UP, or closed, position and the

right solvent valve open with solvent flowing through the

right fluid chamber and out through the mixing chamber.

Handle

up

Fig. 2

05767

Solvent out

Solvent

Resin

(A)

Hardener

(B)

Solvent

valve

shown

open