Repair

313643G 7

Repair

Flush the Air Motor

If the motor is sluggish or inefficient, flush it with

non-flammable solvent in a well-ventilated area.

1. Follow the Pressure Relief Procedure. See

page 6.

2. Add several teaspoons of solvent, or spray the sol-

vent directly into the motor.

3. Rotate the shaft by hand in both directions for a few

minutes.

4. Reconnect the air line and slowly apply pressure

until there is no trace of solvent in the exhaust air.

5. Lubricate the motor with a squirt of lightweight oil in

the chamber.

Service

Air Motor

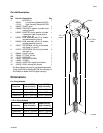

1. To remove the air motor for service, use a 3/16 hex

to remove the three setscrews (9) on the bung

adapter (4).

2. Lower the adapter (4) on the shaft (2) so coupler (3)

is accessible.

3. Use a 1/8 hex to remove the top two setscrews (8)

on the coupler (3).

4. Lift the air motor (1) straight up off the coupler (3).

• If the air motor (1) requires more than installation of

a service kit, it is usually quickest and easiest to

send it to the Graco distributor for repair or replace-

ment.

• If the air motor blades need replacing or foreign

material is present in the motor chamber, an experi-

enced mechanic may remove the end plate opposite

the drive shaft end. Do not pry with a screwdriver. It

will dent the surface of the plate and body, causing

leaks. Use a puller tool, which will remove the end

plate while maintaining the position of the shaft.

Shaft and Agitator Blades

1. Remove the shaft (2) from the drum. Clean with a

compatible solvent and inspect the shaft (2) and

blades (6, 7) for wear or damage.

2. If parts need replacing, follow steps 1-4 under Air

Motor to remove the air motor.

3. Use the 1/8 hex to remove the other two setscrews

(8) on the coupler.

4. Slide the shaft off (2).

5. If needed, use a 3 mm (1/8 in.) hex to remove the

setscrew (8) on the hub assembly (6 or 7). Slide the

hub/blade assembly off of the shaft.

6. To install a new hub/blade assembly, slide it onto the

shaft. The setscrew must always remain on the top,

with the blades hanging down, so the blades will

pass into and out of the bung hole.

NOTE: Air Motor Repair Kits are available. Order Part

207335 for Model 24C728 (low viscosity) or Part 224954

for Model 24C729 (high viscosity).

Reassembly

1. Slide the shaft (2) into the coupler (3). Use a 1/8 hex

to tighten the setscrews (8). Torque to 65 in-lb

(7.3 N•m).

2. Raise the bung adapter (4) on the shaft (2) to recon-

nect to the air motor. Use a 3/16 hex to tighten the

three setscrews (9) on the bung adapter. Torque to

80 in-lb (9 N•m).