– 3 –

IN230000AV

Operation (Continued)

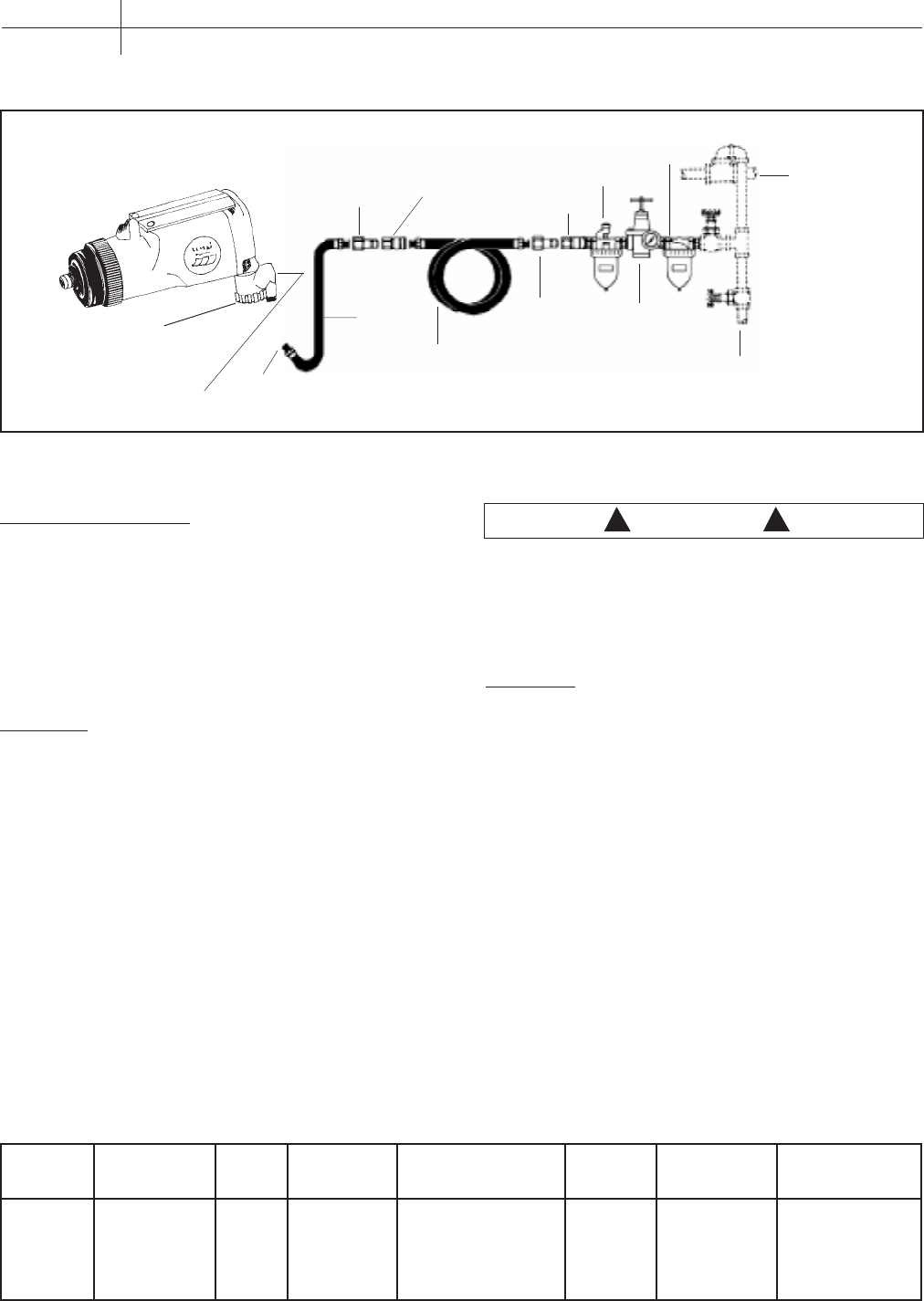

REGULATOR

QUICK

CONNECTOR

(OPTIONAL)

AIR

HOSE

LEADER

(WHIP)

HOSE

QUICK

COUPLER

DO NOT INSTALL A

QUICK COUPLER HERE

REGULATOR

QUICK

COUPLER

(OPTIONAL)

OILER

FILTER

QUICK

CONNECTOR

DRAIN (WATER TRAP)

AIR SUPPLY

Figure 2 - Air Hose Hook-up

AIR TOOL MANUFACTURERS RECOMMEND THAT AN AIR FIL-

TER AND OILER BE USED TO INCREASE THE LIFE OF THE TOOL.

MODELS TL1002, TL1017 AND TL1049

Specifications & Performance

MODEL AVERAGE MAX MAX AIR EXTENDED

# SCFM & PSI RPM TORQUE INLET DRIVE WEIGHT ANVIL

TL1002 5.1 @ 90 7000 230 ft/lb 1/4" NPT (Female) 1/2" Sq 5 lb NA

TL1017 2.4 @ 90 10,000 75 ft/lb 1/4" NPT (Female) 3/8" Sq 2 lb N/A

TL1049 2.5 @ 90 10,000 75 ft/lb 1/4" NPT (Female) 3/8" Sq 3 lb NA

SPEED ADJUSTMENT

The impact wrench should never be used to set torque.

Use a torque wrench to set the torque. Models TL1002,

TL1017 and TL1049 are equipped with regulators for

speed adjustment (See Figure 2).

To remove nuts, set the regulator to the maximum

setting. To install nuts, set the regulator to the minimum

to medium setting. Do not overtighten the nuts.

AIR HOSE

Figure 2 illustrates a recommended air hose hook-up.

NOTE: It is not recommended to install a quick coupler

between the impact wrench and the leader (whip) hose

(See Figure 2).

Using fittings or air hoses which are too small can create

a pressure drop and reduce the power of the tool. For

models TL1002, TL1017 and TL1049, using 3/8" (I.D.)

fittings with 1/4" NPT threads are recommended. Most

compressors are shipped with a short, 1/4" I.D. hose.

For proper performance and more convenience, use a

3/8" I.D. hose. Hoses longer than 50 feet should have a

1/2" I.D.

NEVER CARRY A TOOL BY THE HOSE OR PULL

THE HOSE TO MOVE THE TOOL OR A COMPRES-

SOR. KEEP HOSES AWAY FROM HEAT, OIL AND

SHARP EDGES. REPLACE ANY HOSE THAT IS

DAMAGED, WEAK OR WORN.

STORAGE

The impact wrench must be lubricated before storing.

Follow the air motor lubrication instructions with an

exception to step 4. Only run the impact wrench for 2

to 3 seconds instead of 20 to 30 seconds because more

oil needs to remain in the impact wrench when storing.

Technical Service

For information regarding the operation or repair of this

product, please call 1-800-543-6400. If you are calling

from Ohio or outside the continental United States,

please call collect, 1-513-367-1182.

AIR INLET (OIL HERE

DAILY IF NOT USING

AN AIR TOOL OILER)

WARNING

!

!