WM63-SERIES MIXER • OPERATION AND PARTS MANUAL — REV. #0 (069/27/12) — PAGE 17

INSPECTION

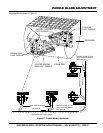

V-BELT CHECK

Visually examine the V-belt (Figure 7) and determine if it

is full of tiny cracks, frayed, has pieces of rubber missing,

is peeling or otherwise damaged.

Also, examine the belt and determine if it is oil soaked or

"glazed " (hard shiny appearance on the sides of the belt).

Either of these two conditions can cause the belt to run hot,

which can weaken it and increase the danger of it breaking.

If the V-belt exhibits any of the above wear conditions

replace the V-belt immediately.

Figure 7. V-Belt Inspection

START/STOP SWITCH

This unit has been equipped with a start/stop switch

(Figure 8), which should be tested every time the unit is

started.

Figure 8. Start/Stop SwitchBLADE CHECK

GLAZED

OIL SOAKED

BROKEN

CORD FAILURE

CRACKS

MISSING RUBBER

SIDEWALL

WEAR

WORN BACK

COVER

PULL OUT

TO START ENGINE

PUSH IN

TO STOP ENGINE

START/STOP

SWITCH

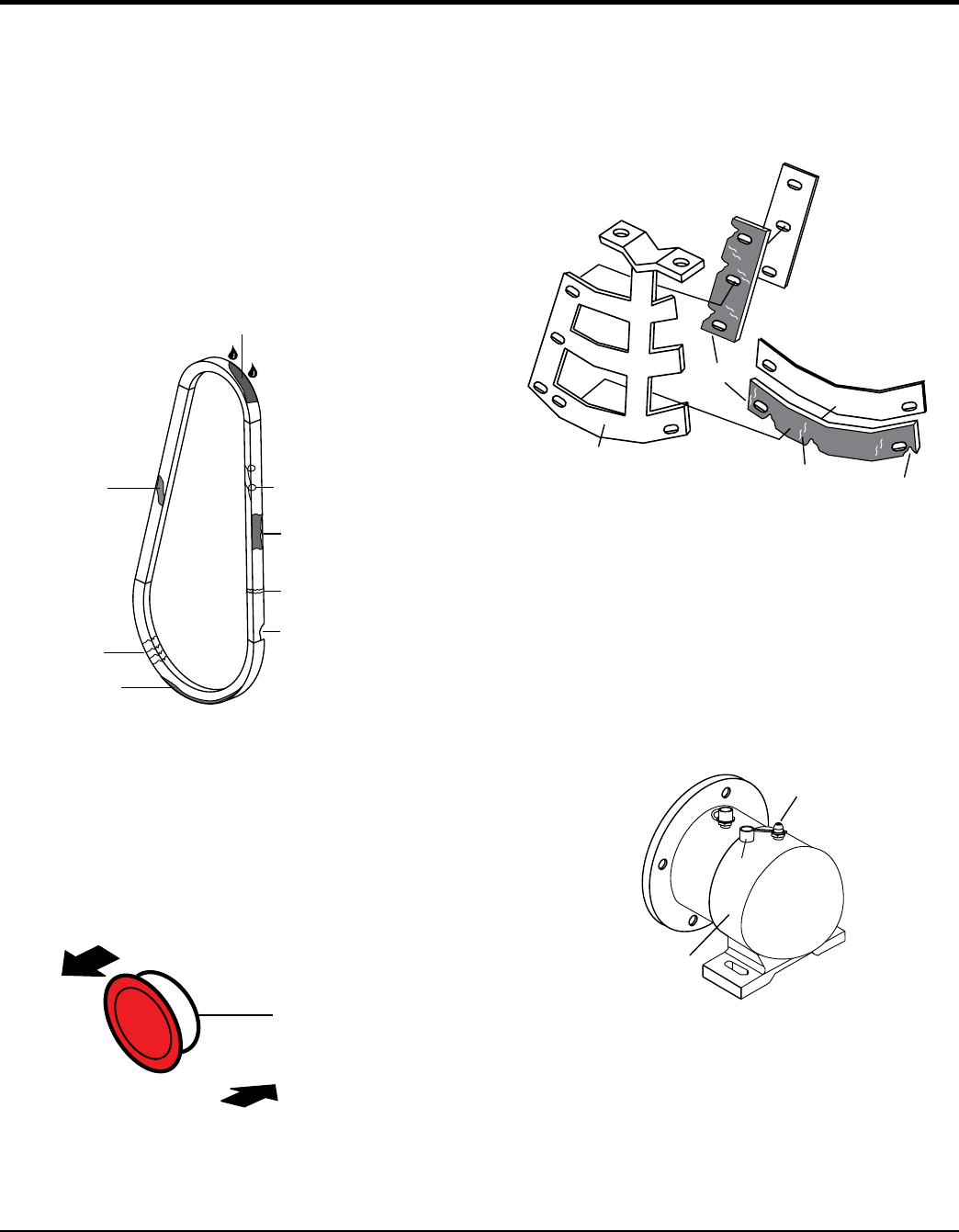

Check for worn or defective paddle blades (Figure 9).

Make sure that all blades are adjusted properly. See blade

adjustment procedure (Figure 13) in this manual. Replace

all defective or damaged blades immediately.

Figure 9. Blade Inspection

GREASE FITTINGS (DUMPING MECHANISM)

Check the drum bearing bracket grease fittings (Figure 10) at

each end of the mixing drum. These grease fittings lubricate

the dumping mechanism. If the dumping handle is stiff or

hard to move, lubricate these grease fittings.

Figure 10. Grease Fittings

Drum Bearing Bracket

S

I

D

E

S

C

R

A

P

E

R

E

N

D

S

C

R

A

P

E

R

MISSING

RUBBER

CRACKS

BLADE

PADDLE

GREASE

FITTING

CAP

DRUM

BEARING

BRACKET