PAGE 8 — WHITEMAN WM-700S, 700P — PARTS & OPERATION MANUAL — REV. #7 (06/21/01)

WM-700S, 700P — OPERATIONS

GENERAL

The Whiteman WM-700 and WM-900 Series plaster and mortar

mixers are quality mixers that have a batch capacity of 2.5 and

3.5 bags respectively. With proper care, they will give continuous

service year-after-year.

BEFORE STARTING

Before starting the engine, read the engine owners manual

and thoroughly understand the safety information.

Check the items listed below:

Oil Levels. Be sure to check the oil levels in the engine and

engine reduction unit before starting the unit.

Hardware. Check all hardware on the mixer before starting.

Periodically inspect all hardware. Loose hardware can

contribute to early component failure and poor performance.

Use the torque chart below as a general guideline and keep

all hardware tight:

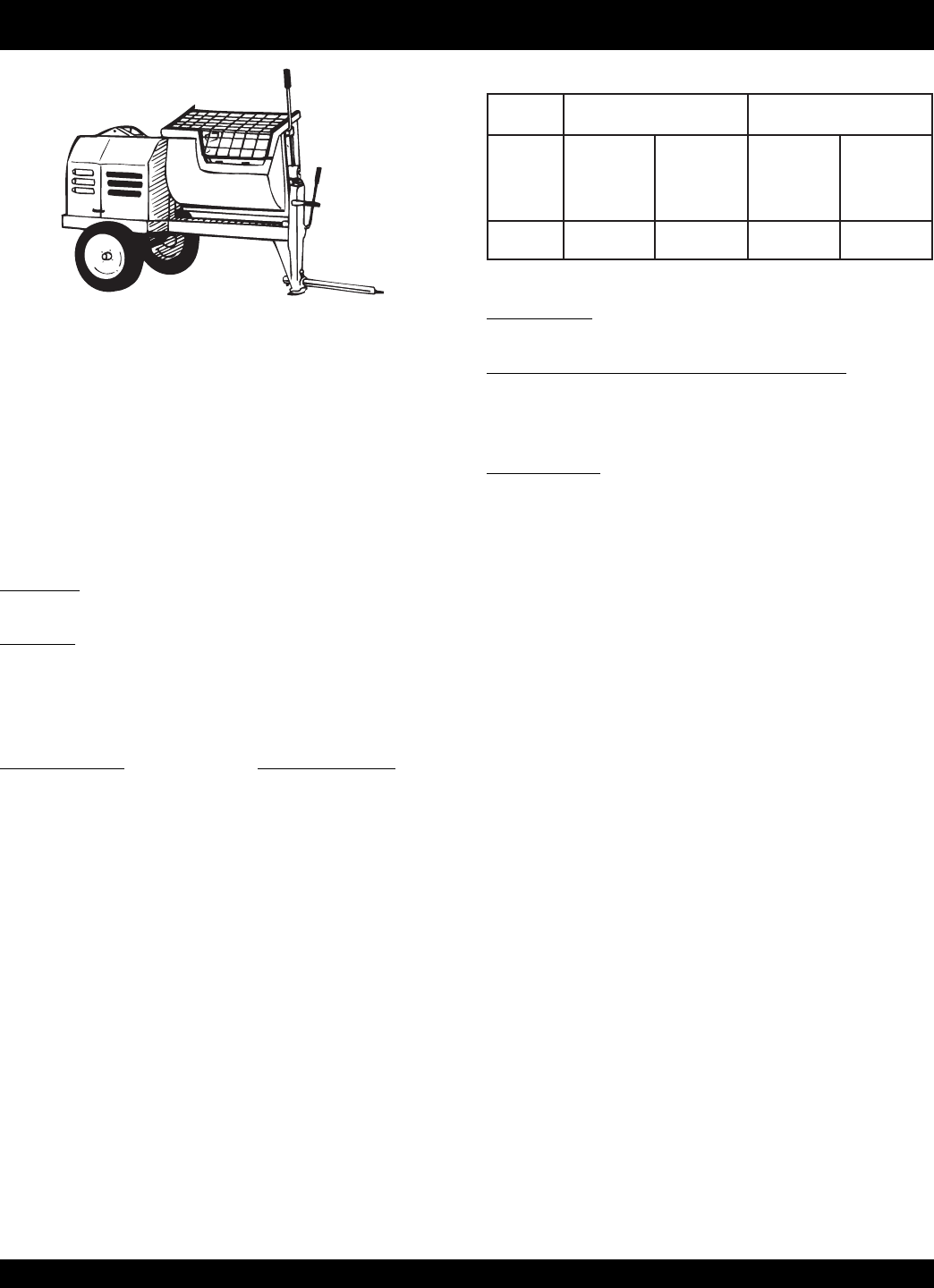

HARDWARE DIA TORQUE (LB./FT.)

%/16

" - 18 14

#/8"

- 16 24

#/8"

- 24 3 7

½" - 13 39

½" - 13 (Grade 8) 90

GASOLINE ENGINE CARE

For care and operation of the gasoline engine, refer to the

engine manufacturer’s operating instructions furnished with

the engine. We recommend draining and refilling the engine

crankcase at least every thirty hours of operation. Check the

engine oil level daily.

Refer to the following chart. For recommend plug sizes.

CONTROLS

KILL SWITCH: (Gasoline Engine Only) Located on the side of

the engine cover.

ENGINE THROTTLE AND CHOKE CONTROLS: Please refer

to the engine owners manual for specific instructions. The

electric motor switch ( electric motor only) located on the motor

— is used to start and stop the mixer.

DUMP LATCH: To dump the tub, grasp the dump handle and

lift the dump latch, then rotate the tub to discharge the mix.

After, discharge, return the tub to the vertical mixing position.

ROTOM

Ø1TLOV511

007MW

Ø1TLOV032

009MW

ESROH

REWOP

PACLIATGIP

/AMEN

NAMETIHW

YDOBNNOC

/AMEN

NAMETIHW

PACLIATGIP

/AMEN

NAMETIHW

YDOBNNOC

/AMEN

NAMETIHW

PH3&½1

545049/P03-5L645049/R03-5L055049/P51-6L155049/R51-6L

CLUTCH

The paddle shaft and mixing blades are engaged and

disengaged by tightening and loosening the drive belts with a

spring loaded idler pulley. To engage the clutch, rotate the lever

counterclockwise. The spring maintains the correct belt tension.

To disengage the clutch, rotate the lever clockwise against the

lever stop. The engine base is slotted to adjust for belt wear and

to bring the idler pulley into operating range.

CAUTION: Stop the engine before allowing anybody to put

their hands in the mixing drum.

WHEEL BEARINGS

After every 3 months of operation, remove the hub dust cap and

inspect the wheel bearings. Once a year, or when required,

disassemble the wheel hubs remove the old grease and repack

the bearings forcing grease between rollers, cone and cage

with a good grade of high speed wheel bearing grease (never

use grease heavier than 265 A.S.T.M. penetration (“No. 2.”) Fill

the wheel hub with grease to the inside diameter of the outer

races and also fill the hub grease cap. Reassemble the hub

and mount the wheel. Then tighten the adjusting nut, at the

same time turn the wheel in both directions, until there is a

slight bind to be sure all the bearing surfaces are in contact.

Then back-off the adjusting nut

!/6

to ¼ turn or to the nearest

locking hole or sufficiently to allow the wheel to rotate freely

within limits of .001" to .010" end play. Lock the nut at this position.

Install the cotter pin and dust cap, and tighten all hardware.

ELECTRIC MOTOR CARE

For lubrication care and operation of the electric motor, refer to

your electric motor instruction booklet furnished with the motor.

Protect the electric motor from dust as much as possible and

keep ventilating openings clean. Do not spray water on the

electric motor.