SPECIFICATIONS

Turntable Section:

Type: 3 speed, fully manual

Motor: Direct Drive- 8 Pole, 3 Phase

Starting Torque: 1.6 kg/cm

Start Time: 0-33.33 RPM in 0.8 sec

Braking System: Electronic Servo Brake

Platter: Aluminum Diecast

Speeds: 33.33, 45, and 78

RPM Wow & Flutter: <0.2% WRMS

Separation: 20 dB

Rumble: -40dB (IEC 98A Unweighted)

-50dB (IEC 98A Weighted)

Power

Consumption: 35 Watts

Pitch Range: +/-10%

OPERATION

Tonearm Section:

Type: Locking collar based

interchangeable tube system

Diecast Aluminum

3-bearing construction

Height Range: 0-6 mm

Cue System: Dampened Lift Lever,

Arm Rest and Arm Clip

Weight: 18 lbs (8.2 kg)

Balance Weight: 7 gram S-weight

75 gram Aluminum Plated

w/ 0-3.5 gram range scale

General:

Dimensions:

370mm(W) by 460mm(D) by 135mm(H)

Weight: 18 lbs (8.2 g)

This turntable was designed to accommodate a variety of different mixing styles. Here are some general

operation guidelines to optimize the performance of the turntable.

1. Do not place the turntable on or near a speaker or subwoofer. This may cause unwanted noise

depending on the environment conditions.

2. ALWAYS use the included Slip Mat during record playback. This Slip Mat was designed to reduce friction

between the platter and the record to allow for rapid back cueing and efficient scratch play.

3. Using the tone arm Cue System may prevent damage to your stylus. First lift the Cue Lever, then

position the tone arm over the desired groove of the record, and finally lower the Cue Lever to slowly

drop the tone arm onto the record.

4. Always secure the tone arm using the Arm Clip when not in use. This can prevent stylus damage and

accidental tone arm engagement.

5. To reduce needle skipping, follow the guidelines in the Tone Arm Setup section of this manual. Too

much weight on a cartridge may cause erratic skipping or stylus damage.

Another guideline that may reduce skipping is back cueing and adjusting playback tempo by applying

pressure towards the center of the record near the spindle as indicated below.

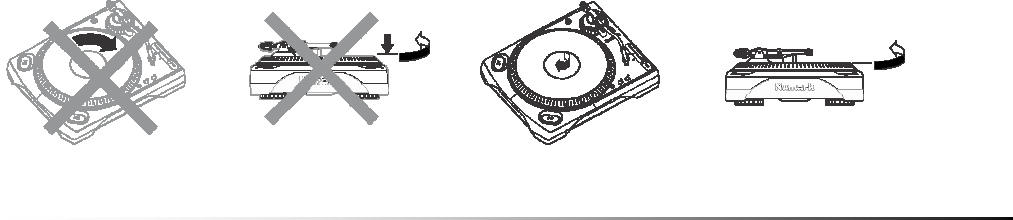

Skipping induce by rapid cueing or scratching may be reduce by applying inward pressure to the side of

the record instead of applying pressure down on the record (see diagram below.)

PAGE 11 SPECIFICATIONS / OPERATION