10 18-CD22D1-8

Installer’s Guide

DUCT CONNECTIONS

Air duct systems should be installed in accordance with

standards for air conditioning systems, National Fire

Protection Association Pamphlet No. 90. They should

be sized in accordance with ACCA Manual D or which-

ever is applicable.

Central furnaces, when used in connection with cooling

units, shall be installed in parallel or on the upstream

side of the cooling coil to avoid condensation in the heat

exchanger. With a parallel flow arrangement, the damp-

ers or other means used to control flow of air shall be

adequate to prevent chilled air from entering the fur-

nace, and if manually operated, must be equipped with

means to prevent operation of either unit unless the

damper is in full heat or cool position.

On any job, flexible connections of nonflammable mate-

rial may be used for return air and discharge connections

to prevent transmission of vibration. Though these units

have been specifically designed for quiet, vibration free

operation, air ducts can act as sounding boards and could,

if poorly installed, amplify the slightest vibration to the

annoyance level.

When the furnace is located in a utility room adjacent

to the living area, the system should be carefully de-

signed with returns to minimize noise transmission

through the return air grille. Although these furnaces

are designed with large blowers operating at moderate

speeds, any blower moving a high volume of air will

produce audible noise which could be objectionable

when the unit is located very close to a living area. It is

often advisable to route the return air ducts under the

floor or through the attic. Such design permits the in-

stallation of air return remote from the living area

(i.e. central hall).

When the furnace is installed so that the supply ducts

carry air circulated by the furnace to areas outside the

space containing the furnace, the return air shall also

be handled by a duct(s) sealed to the furnace and termi-

nating outside the space containing the furnace.

RETURN AIR DUCT SYSTEMS

Where there is no complete return duct system, the re-

turn connection must be run full size from the furnace

to a location outside the utility room, basement, attic,

or crawl space.

Do Not install return air through the back of the furnace

cabinet

Do Not install return air through the side of the furnace

cabinet on horizontal applications.

NOTE:

Minimum return air temperature is 55° F.

All return air duct systems should provide for installa-

tion of return air filters.

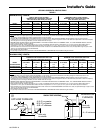

PREPARATION FOR UPFLOW BOTTOM AND SIDE

RETURN AIR FILTER INSTALLATION

All return air duct systems should provide for installa-

tion of return air filters.

1. Determine the appropriate position to set the

furnace in order to existing supply and return

ductwork.

2. The return air filter and rack are shipped in either

the bottom or side location. Remove the filter and

filter rack by first turning the two latches on the

blower door and tilting the door forward to remove.

Remove the filter by sliding it out of the rack.

Compress the spring loaded filter rack to disengage

the retaining pins/screws from the furnace sides

and slide the filter rack out.

The filter rails are spring loaded for automatic

adjustment to allow standard size, locally obtainable

replacement filters. The filter rack itself slides to

adjust to the required width needed for bottom or

side return.

3. For upflow side return installations, remove the

insulation around the opening in the blower compart-

ment.

4. The side panels of the upflow furnace include

locating notches that are used as guides for cutting

an opening for return air, refer to Figure 10 and the

outline drawing on page 5 for duct connection

dimensions for various furnaces.

5. If a 3/4" flange is to be used for attaching the air

inlet duct, add to cut where indicated by dotted

lines in Figure 10. Cut corners diagonally and bend

outward to form flange.

6. If flanges are not required, and a filter frame is

installed, cut between locating notches (See Figure

10).

7. The bottom panel of the upflow furnace must be

removed for bottom return air. After removing the

filter and filter rack, lay the furnace on its back.

Remove the two 5/16" hex screws securing the front

of the bottom channel to the cabinet. Rotate the

channel downward (or remove by lowering the front

edge of the channel and pulling forward). Slide the

bottom return air panel out of the cabinet. Rotate

the front channel to its original position and rein-

stall the two 5/16” screws.

8. The filter retainer is factory supplied for upflow bot-

tom return. Use the filter retainer on side or bot-

tom if filter is to be used within the furnace cabinet

on upflow only installations.