Fluid Supply

16 312775G

Fluid Supply

Requirements

ProMix models are available to operate air spray or

air-assisted systems with a capacity of up to 3800

cc/min.

• Fluid supply pressure tanks, feed pumps, or circu-

lating systems can be used.

• Materials can be transferred from their original con-

tainers or from a central paint recirculating line.

• For an airless system, the user must supply a gun

trigger signal to the ProMix 2KS.

• See manual 313599 for Coriolis meter installation

and operation instructions.

• If you are using dynamic dosing, see Fluid Connec-

tions at right and also see Setup the Fluid Mani-

fold for Dynamic Dosing on page 18.

NOTE: The fluid supply must be free of pressure spikes,

which are commonly caused by pump stroke change-

over. If necessary, install pressure regulators or a surge

tank on the ProMix fluid inlets to reduce pulsation. Con-

tact your Graco distributor for additional information.

Fluid Connections

1. Connect the solvent supply lines.

a. Connect the solvent supply line to the 1/4 npt(f)

solvent purge valve inlet. See F

IG. 6.

b. Multiple color system: also connect a solvent

supply line to the color change stack (Q), top

valve 4 or 5. See F

IG. 7.

NOTE: Solvent supplied by a single source can cause

cross contamination and damage to the system. Install

check valves or use separated solvent sources.

2. Connect the component A supply line(s).

Single color system: connect component

supply line to the component A flow meter

inlet.

Multiple color system: connect compo-

nent A supply lines to the color change

valve stack (S) inlets. See F

IG. 7. The color

number is marked on the valve air supply

line.

NOTE: Paint Recirculating System Only

• The color change valves have two fluid

ports for each individual valve. If you are

recirculating paint, plumb the valves in one

port and out the other.

• Another option is to use a tee fitting to recir-

culate.

NOTE: Verify that all unused fluid ports on the color

change valve stack are plugged before operation. An

open port will leak fluid.

3. Connect the component B line to the component B

flow meter inlet.

NOTE: The component A and B fluid meter inlets have

fluid check valves to prevent backflow from fluid supply

pressure fluctuations. Backflow can cause ratio inaccu-

racies.

4. Connect the gun fluid supply line between the fluid

manifold static mixer outlet and the gun fluid inlet.

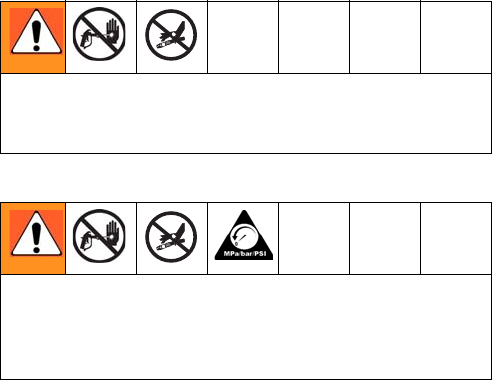

Do not exceed the pressure rating of the lowest rated

component. See the identification label (F

IG. 1 on page

4).

To reduce the risk of injury, including fluid injection,

you must install a shutoff valve between each fluid sup-

ply line and the fluid manifold assembly. Use the

valves to shut off fluid during maintenance and service.