32 18-CD22D1-8

Installer’s Guide

Input rate changes can be made by adjusting the mani-

fold pressure (min 3.0 - max 3.7 in. W.C. - Natural Gas)

or changing orifices (orifice change may not always be

required). If the desired input rate can not be achieved

with a change in manifold pressure, then the orifices

must be changed. LP installations will require an orifice

change.

Installation of this furnace at altitudes above 2,000 ft.

(610m) shall be in accordance with local codes, or in the

absence of local codes, the National Fuel Gas Code,

GAS FLOW IN CUBIC FEET PER HOUR

2 CUBIC FOOT DIAL

SEC. FLOW SEC. FLOW SEC. FLOW SEC. FLOW

8 900 29 248 50 144 82 88

9 800 30 240 51 141 84 86

10 720 31 232 52 138 86 84

11 655 32 225 53 136 88 82

12 600 33 218 54 133 90 80

13 555 34 212 55 131 92 78

14 514 35 206 56 129 94 76

15 480 36 200 57 126 96 75

16 450 37 195 58 124 98 73

17 424 38 189 59 122 100 72

18 400 39 185 60 120 104 69

19 379 40 180 62 116 108 67

20 360 41 176 64 112 112 64

21 343 42 172 66 109 116 62

22 327 43 167 68 106 120 60

23 313 44 164 70 103 124 58

24 300 45 160 72 100 128 56

25 288 46 157 74 97 132 54

26 277 47 153 76 95 136 53

27 267 48 150 78 92 140 51

28 257 49 147 80 90 144 50

TABLE 13

▲

CAUTION

!

Replace and/ or tighten all plugs removed or loosened

when adjusting gas pressure. Leak check the fittings

before placing the furnace into regular service.

Failure to follow this warning could result in fire, ex-

plosion, or property damage.

NOTE:

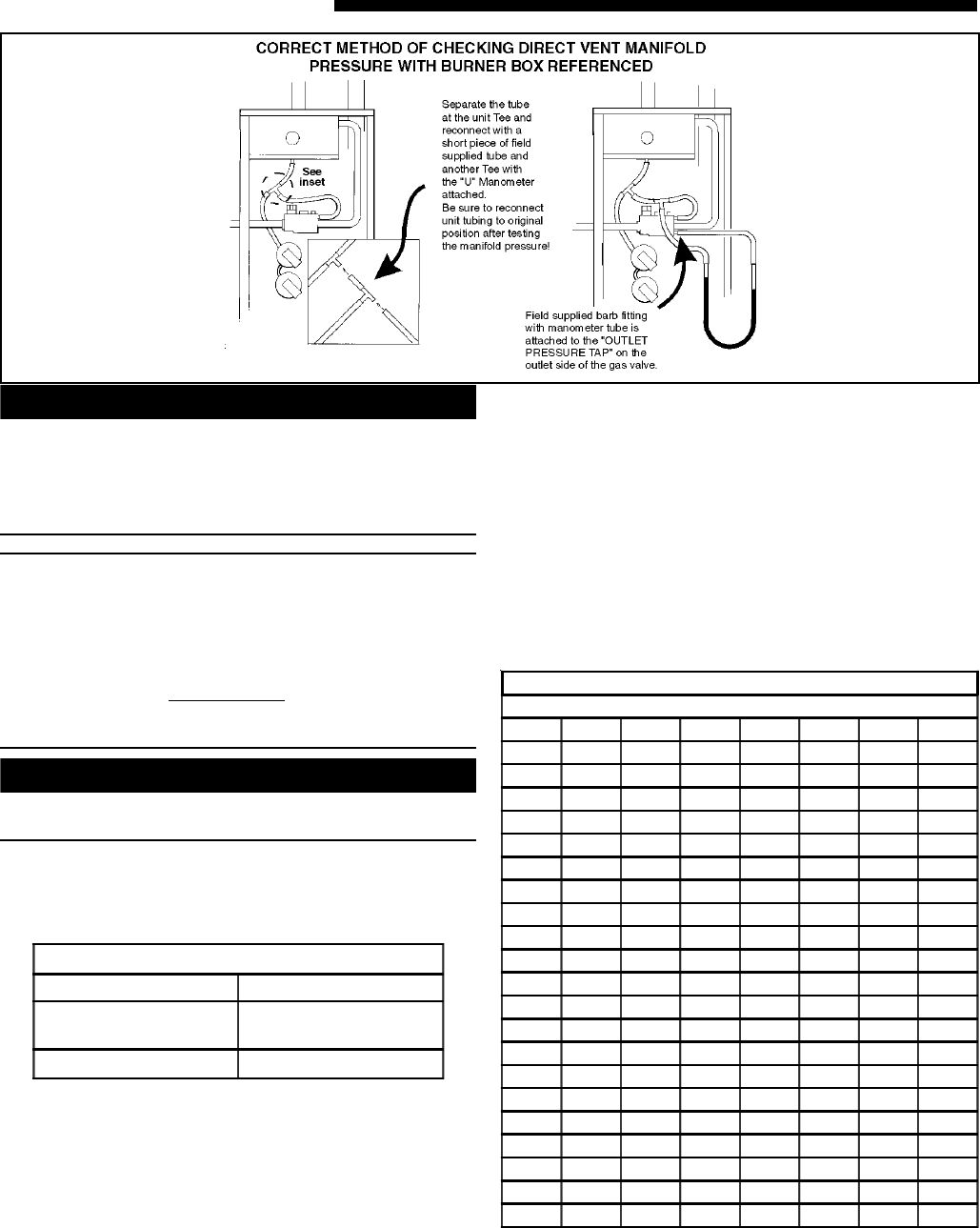

The manifold pressure must be referenced to the

burner box. The burner box pressure tap equalizes the

gas valve pressure regulator. Manifold pressure is

checked by installing a tee (field supplied) in the tub-

ing, between the tee coming from the burner box tube

and the gas valve,

in addition to the regular gas valve

pressure tap on the outlet side of the gas valve. See

Figure 51.

▲

CAUTION

!

Replace manifold pressure tap threaded plug and leak

check after checking/ adjusting manifold gas pressure.

Table 11 lists the main burner orifices used with the fur-

nace. If a change of orifices is required to correct the

furnace input rating refer to Table 14.

TABLE 12

FINAL MANIFOLD PRESSURE SETTINGS

FUEL PRESSURE

NATURAL GAS 3.5" W.C.

LP GAS 11.0" W.C.

HIGH ALTITUDE DERATE

Input ratings (BTUH) of these furnaces are based on

sea level operation and should not be changed at eleva-

tions up to 2,000 ft.

If the installation is 2,000 ft. or above, the furnace input

rate (BTUH) shall be reduced 4% for each 1,000 ft.

above sea level. The furnace input rate shall be checked

by clocking the gas flow rate (CFH) and multiplying by

the heating value obtained from the local utility sup-

plier for the gas being delivered at the installed altitude.

Q