H3123 Electric Guitar Kit -9-

Like the guitar body, the guitar neck is mostly

complete from the factory; however, the neck

headstock can be customized to reflect personal

taste. Additional cutting, inlay, or design work can

give an otherwise ordinary guitar that custom look

that sets it apart from others! Note—Take your

time with this sub-section and consider testing

ideas in scrap wood before performing the work

on the actual headstock.

To sand the guitar neck:

1. Wear an ANSI-approved dust mask and

safety glasses when sanding wood!

2. Perform any custom cutting, inlay, or design

work to the neck headstock.

3. Using the sanding technique described in the

previous sub-section, sand the entire guitar

neck, EXCEPT for the fingerboard surface

(Figure 9). Note—Sanding the fingerboard

will affect the playability of the guitar, and

could lead to unrepairable damage.

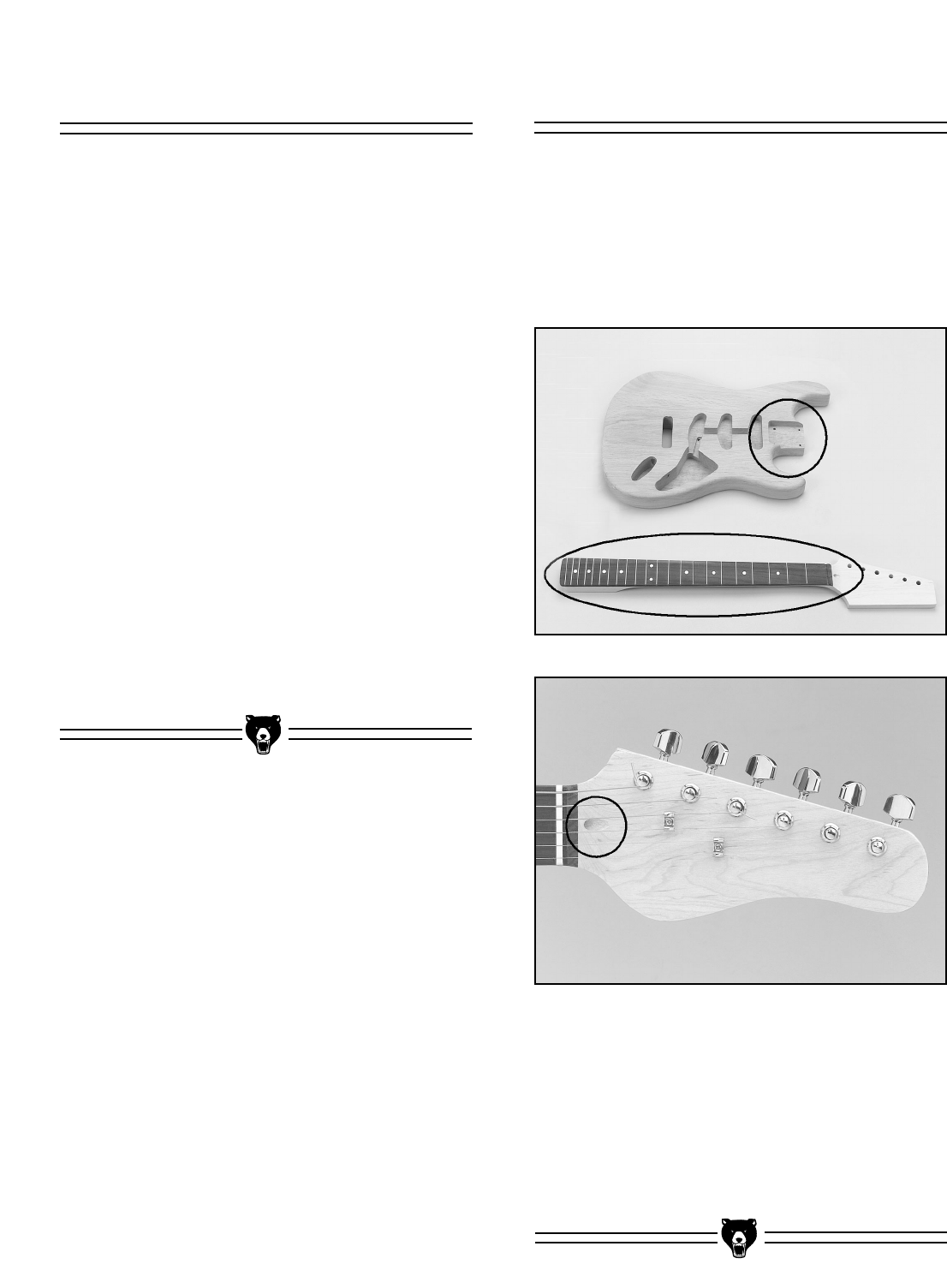

Neck

In preparation for the finish coating, the fol-

lowing parts of the guitar (Figures 9 & 10)

need to be covered with masking tape:

• Neck Pocket

• Fingerboard

• Truss Rod Cut-Out

Masking Tape Areas

Figure 9. Neck pocket and fingerboard areas.

Use a small stick of wood to carefully press all the

masking tape edges securely to the guitar pieces.

The finish coat can seep under these edges,

especially near corners, uneven edges, and

where the frets meet the fingerboard. Note—

Failure to correctly mask off these areas could

result in unrepairable damage to the guitar.

Figure 10. Truss rod area (hardware should not

be installed at this time).