90

In 1934, Electro-Voice invented the hum-bucking coil for micro-

phones, still an industry standard almost 70 years later. The inven-

tion was the beginning of EV’s success in building microphones,

but not the end. Electro-Voice continues to set new standards for

microphone design today. Electro-Voice was the first manufacturer

to use neodymium-based magnet structures (N/DYM

®

) in its

microphones, thus achieving higher output and condenser-like

qualities such as crystal clarity and reliable performance. Electro-

Voice’s goals in developing microphone technologies have always

been the same: providing highest sound quality, achieving better

and more comfortable handling for the user, and continuing the

company’s tradition of legendary reliability and warranty support.

Its long list of patents attests to its success in meeting these goals.

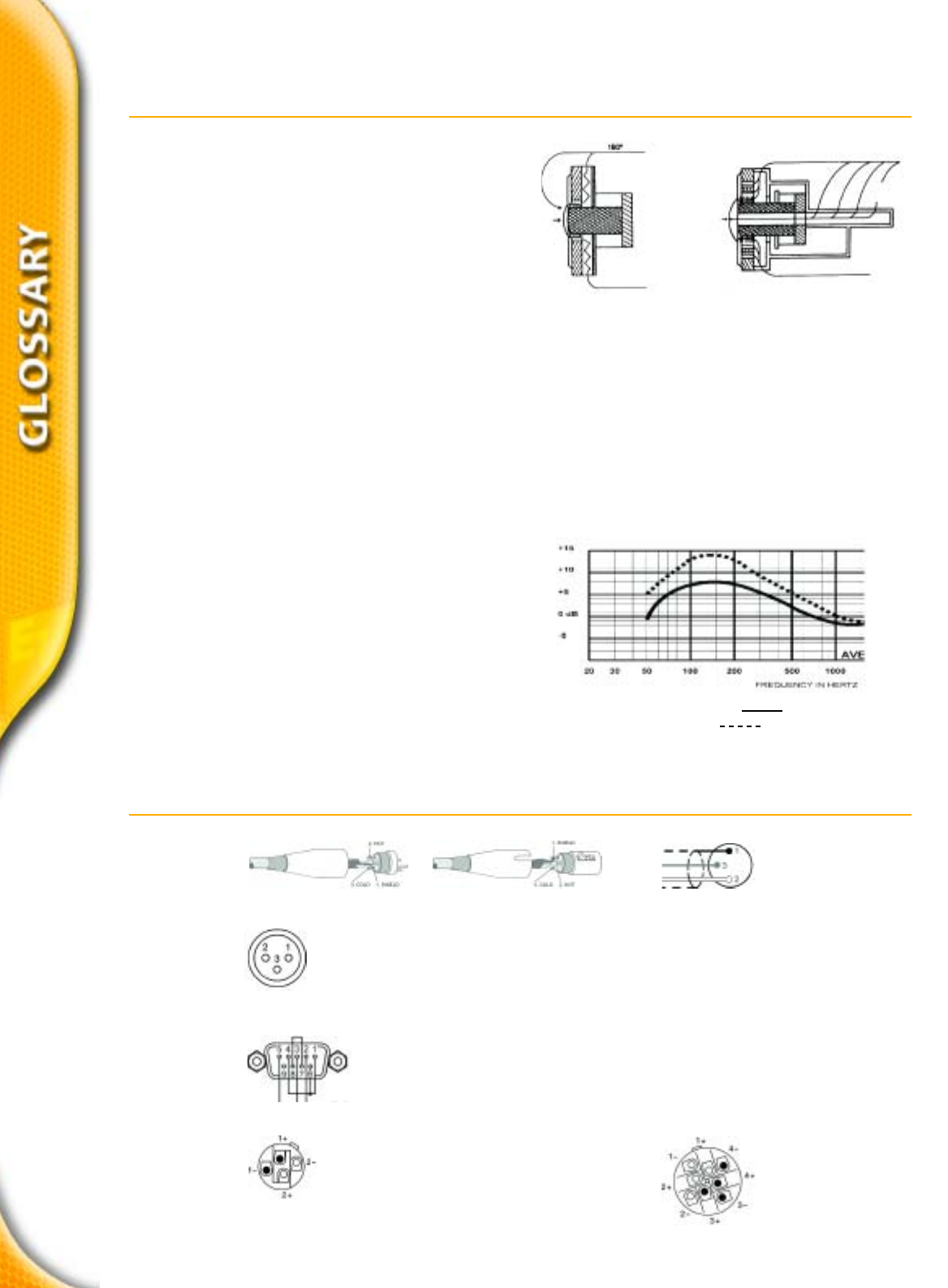

Variable-D

®

Normal microphones generate increased bottom end when used

close up. This is typically called the “proximity effect.” While some

lead vocalists like this effect and use it to enhance their perform-

ance, it is attainable only in closeup situations. When the distance

between the microphone and the source is extended, the sound

quality changes dramatically. Electro-Voice’s patented Variable-D

®

eliminates this disadvantage. On the rear side of the diaphragm

there is a perforated pipe (interference duct) with precise sonic slots

at set distances. The duct provides maximum damping which is

completely uncoloured and undistorted at 180-degree off-axis,

ensuring the same frequency response as if the source was nearly

on-axis.

Variable-D

®

designed microphones can be used very close to other

sound sources with no loss in clarity or definition. This makes them

the preferred choice for tight vocals and challenging instruments

such as brass. Variable-D

®

microphones like the RE20 and RE27 are

favorites with broadcast show hosts, vocal booths, voice-over stu-

dios, and professional touring or rental companies.

VOB

™

Electro-Voice’s unique VOB™ technology (Vocal-Optimized Bass)

reduces low-frequency distortion in the microphone’s output. Critical

damping of the low-frequency resonant peak results in a microphone

that replaces the “muddiness” found in competitive models with

greater warmth and increased vocal intelligibility. With a wider range

of working distances than other microphones, this intelligibility

ensures a clean, clear, consistent sound that “cuts through the mix.”

VOB™ counteracts proximity effect, sibilance, and P-popping, thus

assuring maximum vocal intelligibility and musical clarity.

with VOB™

without VOB™

Normal mic Variable-D

®

mic

Microphone Technologies

PIN - Arrangements

Electronic

Microphones

TA4F (not shown)

used in N/DYM

wireless

Pin 1: Common

Pin 2: Audio

Pin 3: Bias

Pin 4: Not used

Balanced (XLR)

Pin 1: Shield

Pin 2: Signal +

Pin 3: Signal -

Balanced (XLR)

Pin 1: Shield

Pin 2: Hot

Pin 3: Cold

Pin 5: common

Pin 6: parallel to 1 + 4

Pin 7: parallel to 8

Pin 8: parallel to 7

Fullrange Pin 1: LF/HF +/-

Pin 2: Not connected

Biamp Pin 1: LF

Section +/-

Pin 2: HF Section +/-

Subwoofer Pin 1: LF input +/-

System

Pin 1 in:

LF +/- Pin 2! out

Pin 2 in:

LF +/- Pin 1! out

Pin 3 in:

MB+/- Pin 3 out

Pin 4 in:

HF +/-

Pin 4 out

Pin 1: parallel to 4 + 6

Pin 2: TxD

Pin 3: RxD

Pin 4: parallel to 1 + 6

PC inter

face

(RS 232)

Speakers

male female