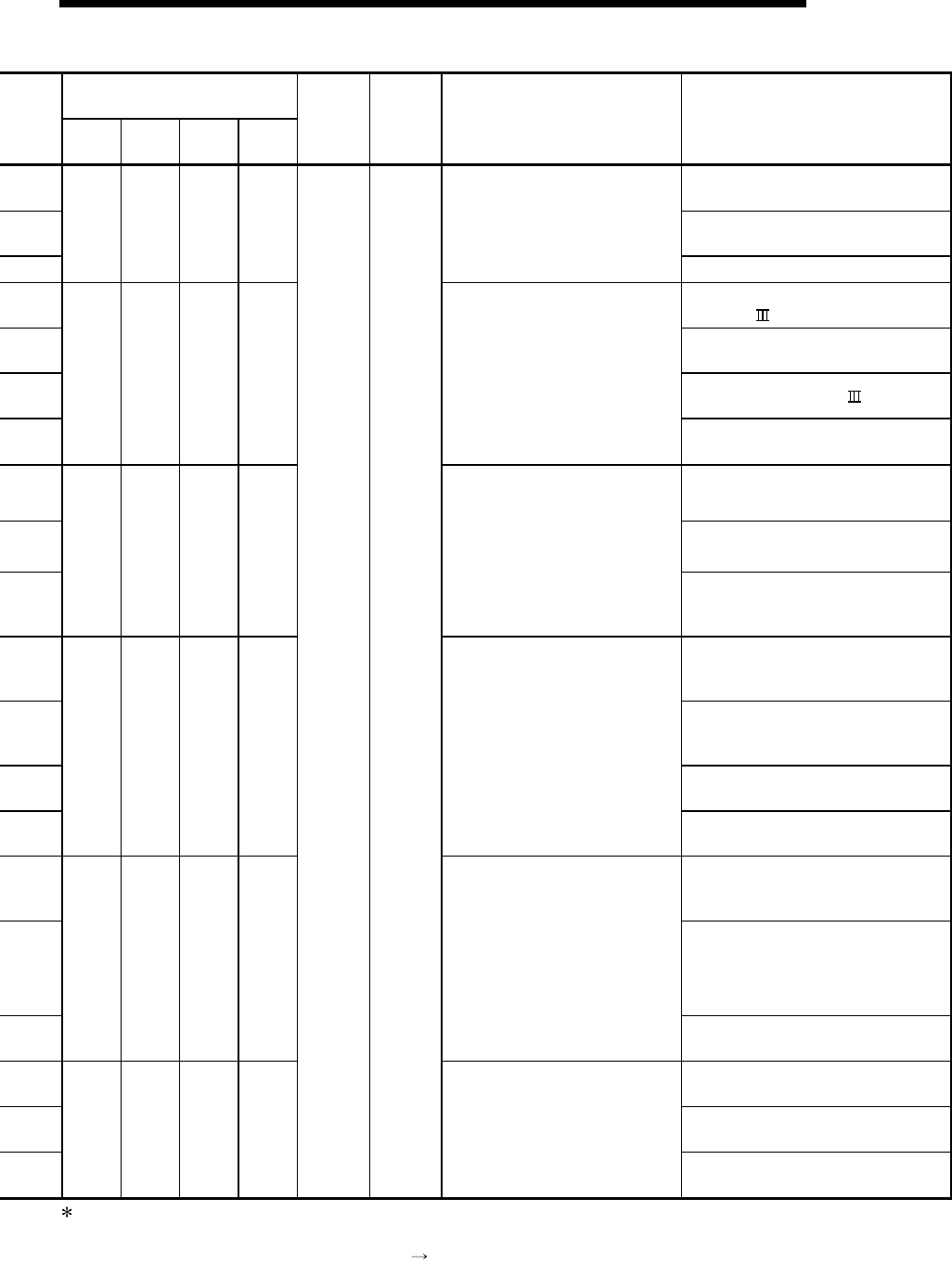

15 - 45

MELSEC-Q

15 TROUBLESHOOTING

Related buffer memory address

Axis 1 Axis 2 Axis 3 Axis 4

Error

check

timing

Error

process-

ing

Check point Corrective action

Review operation program.

Take measures against noise.

— — — —

Change QD75MH.

Connect the connector of the

SSCNET

cable.

Wipe dirt at the surface away.

Change the SSCNET

cable.

— — — —

Take noise suppression measures

Change the servo amplifier.

Change the parameter value to

within the setting range.

— — — —

Change the servo amplifier.

Change the servo amplifier.

The drive method is reviewed.

Review environment so that ambient

temperature is 0 to 55°C.

— — — —

Change the servo amplifier.

Review environment so that ambient

temperature is 0 to 40°C.

• Reduce load.

• Review operation pattern.

• Use servomotor that provides

larger output.

— — — —

Change the servomotor.

Change the cooling fan of the servo

amplifier.

Remove the foreign matter.

— — — —

Always

Imme-

date

stop

Change servo amplifier.

:

The error check timing is shown below.

• When servo amplifier is power ON.

• When the QD75MH detects the rising edge (OFF

ON) of the PLC READY signal [Y0].

• When servo amplifier is reset.

• When the QD75MH is power ON.