11

6.4 Application Precautions

Although the Cal=Trak’s dynamic pressure effects are very small, in some circumstances they may affect the measurement or interact with

the device under test. For the above reasons, certain precautions should be observed when using a Cal=Trak.

Initial Pressure Pulse

The initial pressure pulse is small, about 1% of an atmosphere or less. However, even so small an increase may affect some very sensitive

transducers for several seconds. Two examples of this are the resonant transducers used in LFE systems such as the DH Instruments

Molbloc or capillary-based systems. For this reason, the LFE instrument may not be accurate for a number of seconds after the start and the

end of a Cal=Trak measurement cycle. When calibrating such systems, a stable flow source should be used and the LFE read before and

after the Cal=Trak cycle.

Intra-Cycle Pressure Change

After the initial brief pressure pulse, the change in insertion pressure is typically 0.1% of an atmosphere (~0.1 kPa or 1 cm water column).

This is usually insignificant. For example, flow from a 100 kPa gauge pressure (15 psi) source will change by 0.1%. However, very low

pressure sources will show larger flow change during a Cal=Trak cycle and may require compensating calculations to achieve Cal=Trak’s

best applied accuracy.

Inventory (Dead) Volume

Inventory volume consists of all the space contained between the flow source’s point of restriction and the timed portion of the cylinder.

This includes tubing, empty space within the Cal=Trak base, the lower portion of the measuring cylinder and any other space contained

within the test setup.

It is important to keep inventory volume to a minimum. Excess inventory volume amplifies

the effects of minute pressure variations within

the Cal=Trak cell. In extreme cases, the excess volume also prevents gas pressure from accelerating the piston properly, causing significant

errors in readings. Ideally, the volume contained between the cell and the flow source should be on the order shown in Table 1

, which also

shows the volume as an equivalent length of tubing.

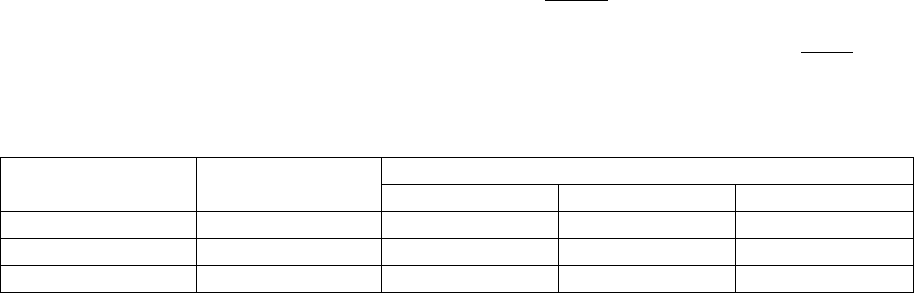

Table 1 Recommended Maximum External Volume and Tubing Lengths

Recommended Maximum Length—meters (inches)

Cell Size

Recommended Max.

Volume (cc)

3mm ID (1/8“) 6mm ID (1/4“) 9mm ID (3/8“)

Small (SL-500-10) 9 1.2 (47.2”) 0.3 (11.8”) N/A

Medium (SL-500-24) 46 6.5 (256”) 1.6 (63.0”) 0.7 (27.6”)

Large (SL-500-44) 118 16.7 (658”) 4.2 (165”) 1.9 (74.8”)

6.5 Comparison vs. Calibration

Calibration consists of comparing an instrument with one of significantly greater accuracy (ideally, at least four times the accuracy of the

device under test--the “4 to 1 rule” widely accepted by industry). We use the term “comparison” in most of the following applications

because, depending upon their respective accuracies, either device can be calibrating (or simply compared with) the other.

For example, a 0.2% LFE can calibrate a 1% mass flow controller, while a 0.15% Cal=Trak can calibrate a 0.6% LFE. On the other hand, a

0.15% lab prover cannot calibrate a 0.15% Cal=Trak to its rated accuracy (or vice-versa). One can calibrate the other to only 0.3% with

great certainty, so we simply call it a comparison.