24

Cal=Trak calibrator. See Chapter 12-5 Accessories or contact Sierra Instruments for details. Wipe only with a damp cloth and do not spray

with liquid solvents or use abrasive cleaners.

Any service to the Sierra Cal=Trak must be performed by Sierra maintenance personnel.

Current service or calibration information and pricing can be received by contacting Sierra Instruments, Inc. at any of the locations listed on

the front cover. Alternatively, you can contact us via our web site www.sierrainstruments.com

.

11.0 Quality Assurance

11.1 Leak Test Procedure

A quality assurance self-test feature is provided to verify proper integrity of the flow cell. It is recommended that the self-check leakage test

be conducted periodically as part of an ongoing quality assurance program. Passing the leak test does not ensure proper function of the

Cal=Trak. It does ensure that total leakage is within the product’s allowable limits. To ensure proper function of the Cal=Trak annual

factory calibration is recommended. The leak test may take as long as 6 hours or more to complete per fitting.

Since the leak test may take several hours, it is recommended to plug the charger into the base during the leak test to prevent the unit from

turning off.

To Initiate the Leak Test

1

Place the Cal=Trak on a flat, vibration-free surface.

2 While in the “Main Menu” install the leak test cable (included with the Cal=Trak base unit) between the 9-pin Cal=Trak

Base Connector and the 9-pin Cell Connector.

3 From the “Main Menu” remove the cell and select “Leak Test”

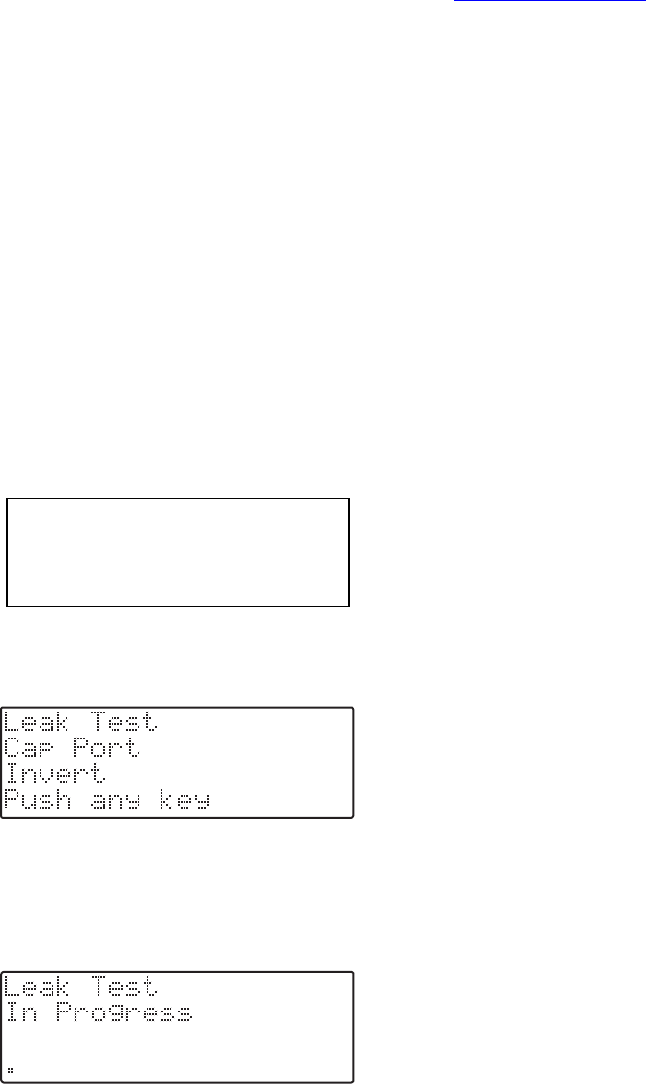

4 After a leak test is initiated, the display will read:

5 Place the leak test plug over either the inlet or the outlet port fitting on the Cal=Trak flow cell.

6 Invert the Cal=Trak flow cell

7 Push any key to commence the leak test. At this point the Cal=Trak will time the descent of the piston. The leak test may

take up to 6 hours to complete. The display will read:

8A If the test is completed successfully, the display will read:

Ma

i

n Menu

Run

Setup

Leak Tes

t