5 - 8

MELSEC-Q

5 DATA USED FOR POSITIONING CONTROL

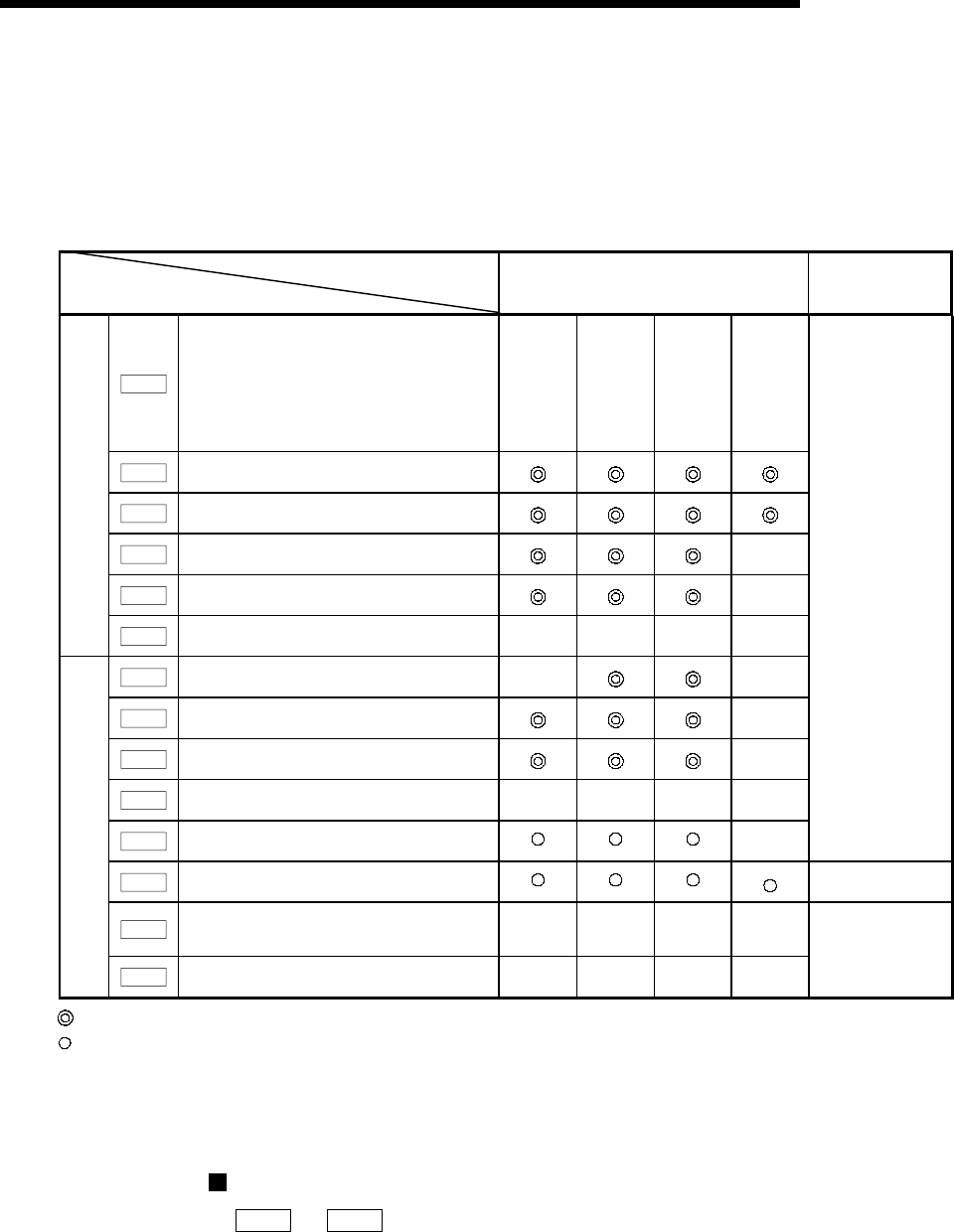

5.1.3 Setting items for OPR parameters

When carrying out "OPR control", the "OPR parameters" must be set. The setting

items for the "OPR parameters" are shown below.

The "OPR parameters" are set commonly for each axis.

Refer to Chapter 8 "OPR control" for details on the "OPR control", and to Section 5.2

"List of parameters" for details on each setting item.

OPR control

OPR parameters

Machine OPR control

Fast

OPR control

Pr.43

OPR method

Near-point dog

method

Count method 1)

Count method 2)

Data set method

Pr.44

OPR direction

Pr.45

OP address

Pr.46

OPR speed

–

Pr.47

Creep speed

–

OPR basic parameters

Pr.48

OPR retry R R R –

Pr.50

Setting for the movement amount after near-

point dog ON

–

–

Pr.51

OPR acceleration time selection

–

Pr.52

OPR deceleration time selection

–

Pr.53

OP shift amount

S S S

–

Pr.54

OPR torque limit value

–

Preset parameters

are used for

machine OPR

control.

Pr.55

Operation setting for incompletion of OPR

–

Pr.56

Speed designation during OP shift S S S –

OPR detailed parameters

Pr.57

Dwell time during OPR retry R R R –

Preset parameters

are used for

machine OPR

control.

: Always set

: Set as required

– : Setting not required (This is an irrelevant item, so the setting value will be ignored. If the value is the default

value or within the setting range, there is no problem.)

R : Set when using the "12.2.1 OPR retry function". ("–" when not set.)

S : Set when using the "12.2.2 OP shift function". ("–" when not set.)

Checking the OPR parameters.

Pr.43

to

Pr.57

are checked with the following timing.

(1) When the "PLC READY signal [Y0]" output from the PLC CPU to the QD75MH

changes from OFF to ON

(2) When the test operation button is turned ON in the test mode using GX

Configurator-QP

(3) When an error check is carried out with GX Configurator-QP