Instrument Changes Model 8904A

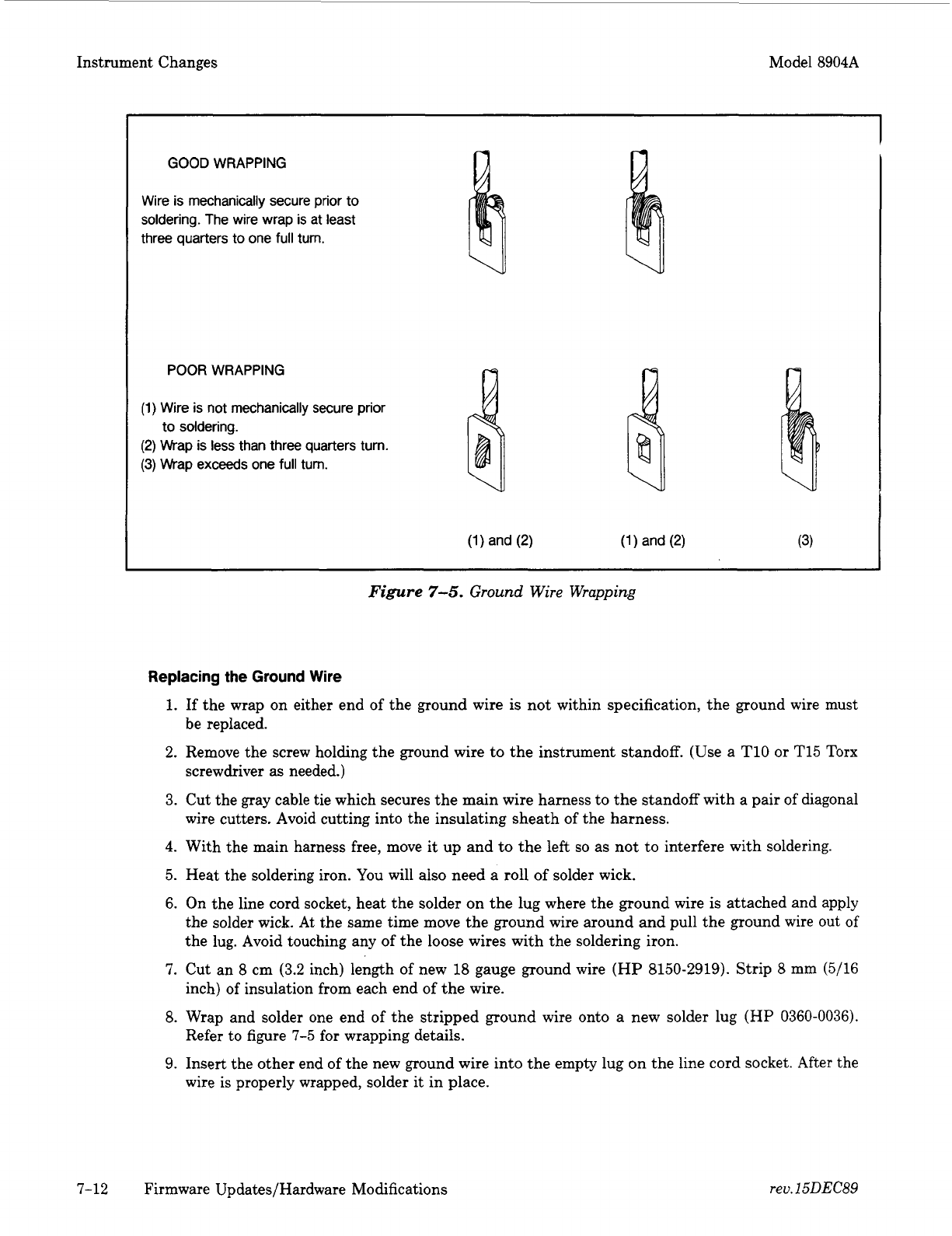

GOOD WRAPPING

Wire is mechanically secure prior to

soldering.

The

wire wrap is at least

three quarters

to

one full turn.

POOR

WRAPPING

(1)

Wire is not mechanically secure prior

(2)

Wrap is less than three quarters turn.

(3)

Wrap

exceeds

one full turn.

to soldering.

~~ ~ ~~

________~

Figure

7-5.

Ground Wire Wrapping

Replacing

the

Ground

Wire

1.

If the wrap on either end of the ground wire

is

not within specification, the ground wire must

2. Remove the screw holding the ground wire to the instrument standoff. (Use a T10

or

T15 Torx

3.

Cut the gray cable tie which secures the main wire harness to the standoff with a pair

of

diagonal

4.

With the main harness free, move

it

up and to the left

so

as not to interfere with soldering.

5.

Heat the soldering iron. You will also need a roll of solder wick.

6. On the line cord socket, heat the solder on the lug where the ground wire is attached and apply

the solder wick.

At

the same time move the ground wire around and pull the ground wire out

of

the lug. Avoid touching any of the loose wires with the soldering iron.

7.

Cut an

8

cm (3.2 inch) length of new

18

gauge ground wire

(HP

8150-2919). Strip

8

mm (5/16

inch)

of

insulation from each end of the wire.

8.

Wrap and solder one end

of

the stripped ground wire onto a new solder lug

(HP

0360-0036).

Refer to figure

7-5

for

wrapping details.

9. Insert the other end of the new ground wire into the empty lug on the line cord socket. After the

wire is properly wrapped, solder

it

in place.

be replaced.

screwdriver as needed.)

wire cutters. Avoid cutting into the insulating sheath of the harness.

7-12 Firmware Updates/Hardware Modifications

rev.

15DEC89