86

MODEL 3081 pH/ORP SECTION 11.0

MAINTENANCE

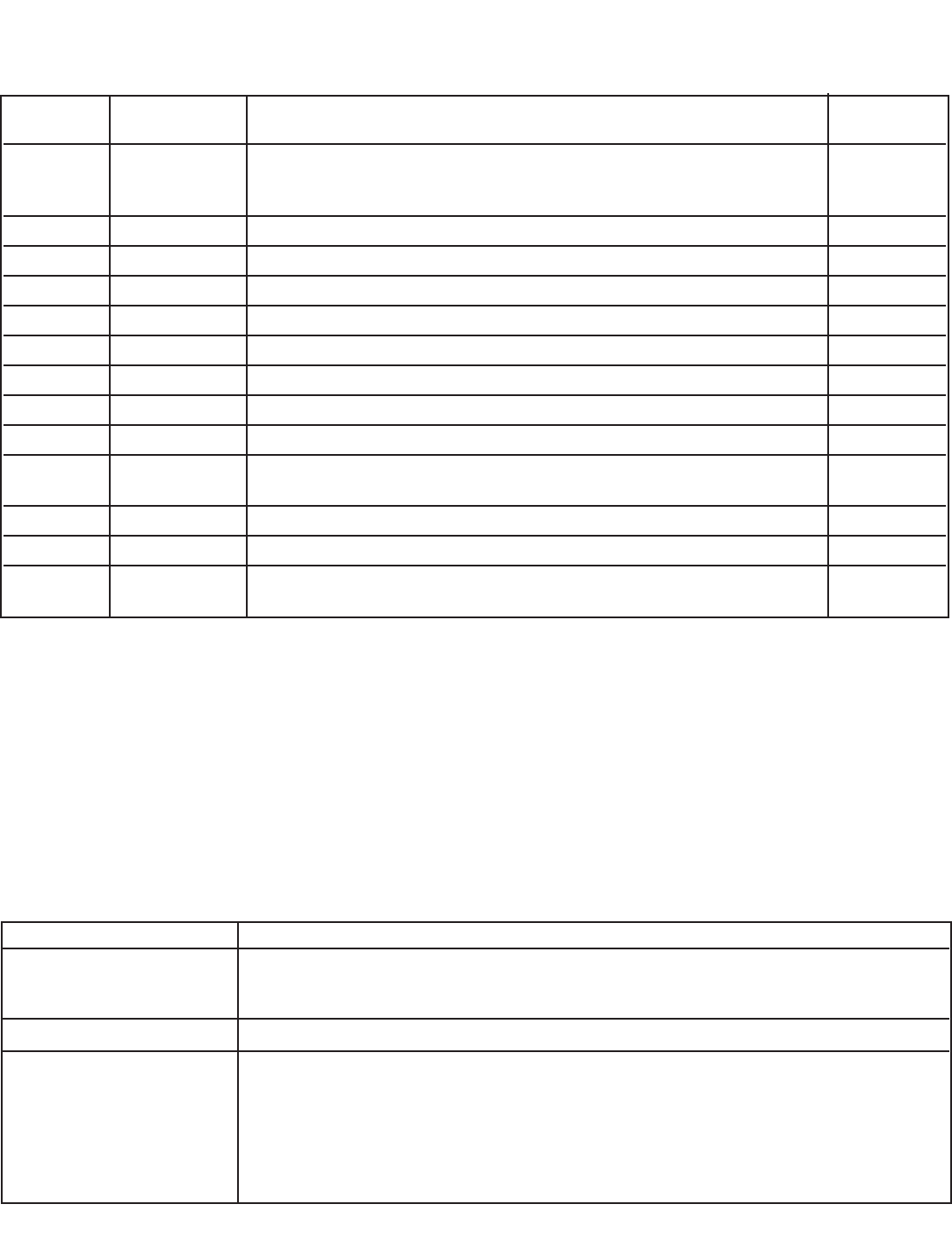

TABLE 11-1. Replacement Parts for Model 3081 pH/ORP Transmitter

PROBLEM CLEANING SUGGESTIONS

Loose scale or debris Use a stream of water from a wash bottle to rinse away solids from the tip of the

sensor. If water does not work, gently wipe the glass bulb and liquid junction with a

soft cloth, tissue, cotton-tipped swab, or a soft bristle brush.

Oil and grease Wash the glass bulb with mild detergent solution and rinse thoroughly with water.

Hard scale (carbonate If wiping the sensor tip with a tissue or cotton swab does not remove the scale, soak the

sulfate scales and glass bulb ONLY in a solution of 5% hydrochloric acid. To prepare the acid solution, add

corrosion products) 15 mL of concentrated hydrochloric acid to 85 mL of water with constant stirring. Keep the

acid away from the liquid junction and from any stainless steel portions of the sensor.

Rinse the sensor thoroughly with deionized water. Some scales (for example, calcium sulfate)

cannot be removed easily with acid. Soaking the glass bulb in a 2% solution of disodium

EDTA may be helpful.

Location in Shipping

Figure 11-1 PN Description Weight

1 23574-02 PCB stack consisting of the CPU (part 3) and analog (part 4) boards, 1 lb/0.5 kg

display board is not included, CPU and analog boards are factory-

calibrated as a unit and cannot be ordered separately

2 23652-01 LCD display PCB 1 lb/0.5 kg

5 33337-02 Terminal block 1 lb/0.5 kg

6 23593-01 Enclosure cover, front with glass window 3 lb/1.5 kg

7 33360-00 Enclosure, center housing 4 lb/1.5 kg

8 33362-00 Enclosure cover, rear 3 lb/1.0 kg

9 6560135 Desiccant in bag, one each 1 lb/0.5 kg

10 9550187 O-ring (2-252), one, front and rear covers each require an O-ring 1 lb/0.5 kg

12 note Screw, 8-32 x 0.5 inch, for attaching terminal block to center housing *

13 note Screw, 8-32 x 1.75 inch, for attaching circuit board stack to center *

housing

14 33342-00 Cover lock 1 lb/0.5 kg

15 33343-00 Locking bracket nut 1 lb/0.5 kg

16 note Screw, 10-24 x 0.38 inch, for attaching cover lock and locking bracket *

nut to center housing

NOTE: For information only. Screws cannot be purchased from Rosemount Analytical.

* Weights are rounded up to the nearest whole pound or 0.5 kg.

11.3 pH SENSOR MAINTENANCE

11.3.1 Frequency of Cleaning

The frequency at which a sensor should be inspected and cleaned can be determined only by experience. If the process

liquid coats or fouls the sensor, frequent cleaning may be necessary. If the process does not contain a high level of sus-

pended solids, the need for regular cleaning will be less. Often an increase in glass impedance indicates the electrode is

becoming fouled and needs cleaning. Refer to Section 8.4 for a description of the glass impedance diagnostic.

11.3.2 Cleaning Procedures