92

MODEL 3081 pH/ORP SECTION 12.0

TROUBLESHOOTING

b. If the sensor was wired with the blue solution ground wire unattached and a jumper between terminals

TB-8 and TB-7, remove the jumper and reattach the blue solution ground wire to TB-8. Keep the gray

reference in wire attached to TB-7.

c. For Rosemount Analytical PLUS (+) and TUpH sensors that do not have an integral preamplifier, attach

the blue solution ground wire to TB-8 or, better, leave the blue wire unattached and jumper TB-7 to TB-8.

d. If the sensor does not have a blue solution ground wire, jumper terminals TB-7 and TB-8.

If the wiring was correct and the glass impedance is still high, go on to step 2.

If correcting wiring errors causes the diagnostic message to disappear, the sensor is in good condition.

If after correcting wiring errors, the glass impedance is still high go on to step 2.

2. Inspect and clean the sensor. Refer to Section 11.3. After cleaning the sensor, calibrate it following the

auto calibration procedure in Section 7.5. Be sure to note the sensor slope.

If cleaning the sensor lowers the impedance below 800 megohms...

a. The sensor is in good condition.

b. Return the calibrated sensor to service.

If cleaning does not lower the glass impedance and the sensor can be calibrated...

a. The sensor is probably in good condition; however, it may be nearing the end of its life. The electrode

slope is a good indicator of remaining life.

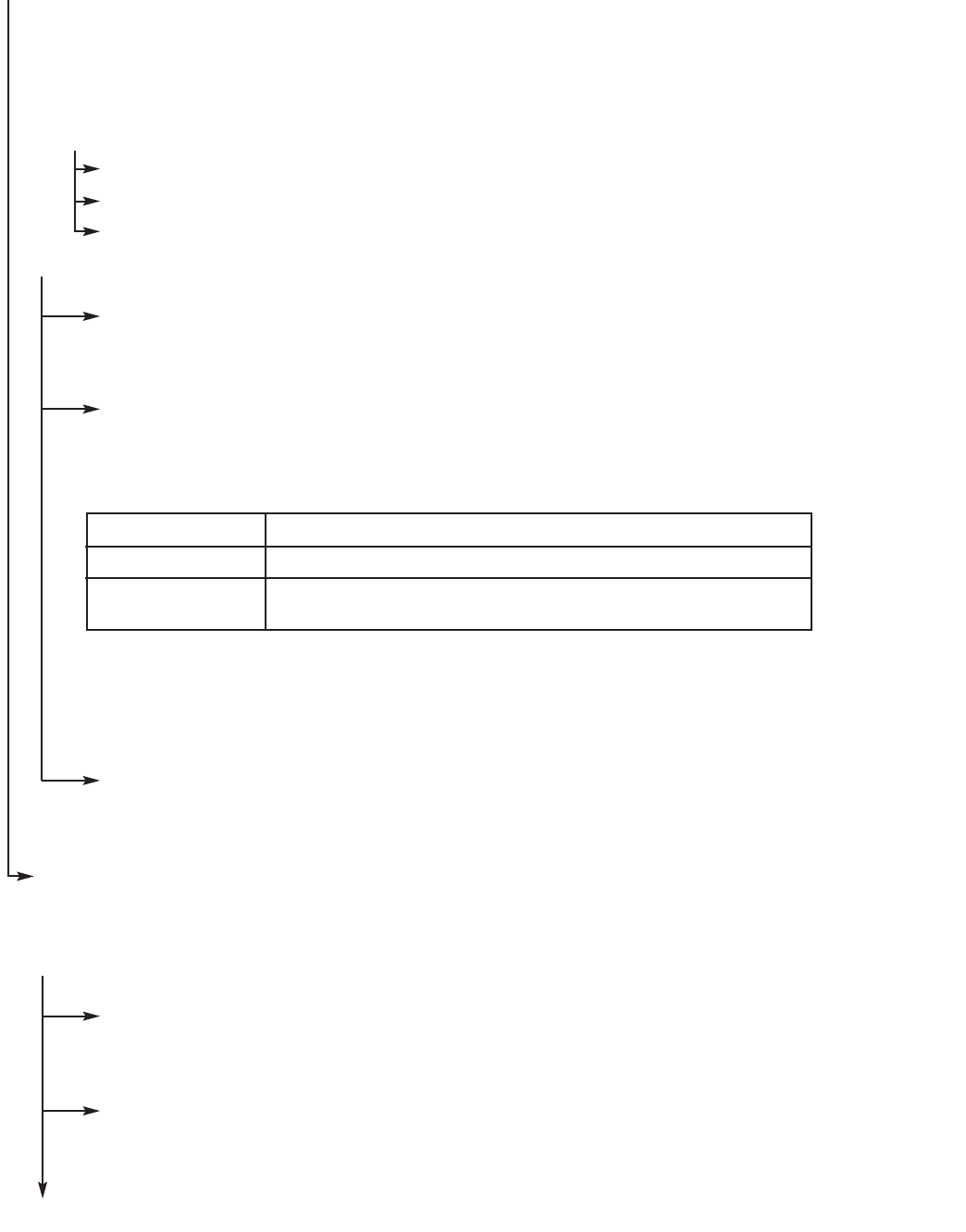

SLOPE CONDITION OF SENSOR

54-60 mV/unit pH Sensor is in good condition.

48-50 mV/unit pH Sensor is nearing the end of its life. Once the slope drops

below 48 mV/unit pH, the sensor can no longer be calibrated.

b. The Glass Fail High (GFH) limit is probably set too low for the sensor. Set the GFH limit to about

150 megohms greater than the measured glass impedance.

c. If the GLASSWArn message was also flashing, raise the GWH limit from its former value by the

same amount GFH was raised from its former value.

If cleaning does not lower the glass impedance and the sensor cannot be calibrated...

The sensor has failed and should be replaced.

If the glass impedance is moderate (between 40 and 800 megohms)...

1. The sensor may be dirty, in which case cleaning it will lower the impedance reading. The sensor may also be

in good condition. The warning and fail limits are simply set too low.

2. Inspect and clean the sensor. Refer to Section 11.3. After cleaning the sensor, calibrate it following the

auto calibration procedure in Section 7.5. Be sure to note the sensor slope.

If cleaning the sensor reduces the impedance...

a. The sensor is in good condition.

b. Return the calibrated sensor to service.

If cleaning does not lower the glass impedance and the sensor can be calibrated...

a. The sensor is probably in good condition; however it may be nearing the end of its life. The electrode

slope is a good indicator of remaining life.