4

PROCEDURES AND SETTINGS BEFORE

OPERATION

4.4 Wiring

4.4.1 Wiring precautions

4 - 5

1

OVERVIEW

2

SYSTEM

CONFIGURATION

3

SPECIFICATIONS

4

PROCEDURES AND

SETTINGS BEFORE

OPERATION

5

FUNCTIONS

6

UTILITY PACKAGE (GX

Configurator-CT)

7

PROGRAMMING

8

TROUBLESHOOTING

4.4 Wiring

This section describes wiring an encoder and controller to the QD64D2.

4.4.1 Wiring precautions

One of the conditions to maximize the QD64D2 functions and make the system high-

reliable, the external wiring has to be laid so that the QD64D2 becomes less subject to

noise.

This section describes the precautions on external wiring.

(1) Inputting a signal of different voltage may result in a malfunction or

mechanical failure.

(2) For 1-phase input, always perform pulse input wiring on the phase A

side.

(3) When pulse status noise is input, the QD64D2 may miscount.

(4) Take the following measures against noise for high-speed pulse input.

(a) Always use a shielded twisted pair cable and ground it on the QD64D2 side.

(b) Wire the shielded twisted pair cables so as not to be in parallel with wires causing

much noise such as power lines or I/O wires while keeping a distance of at least

150 mm (5.91 inch) between such wires. Also install the shielded twisted pair

cables as short as possible.

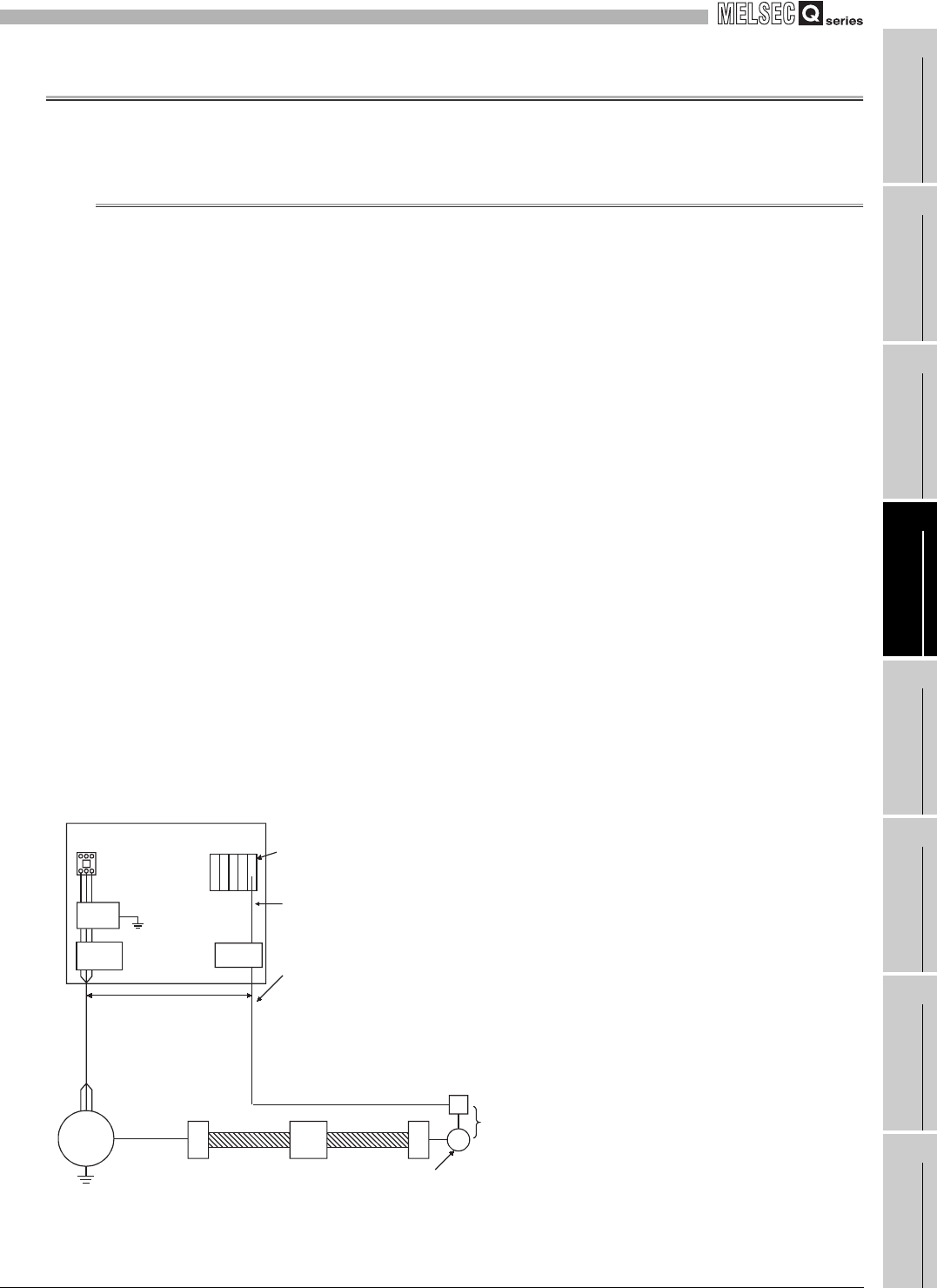

(5) The following diagram shows an example of wiring for measures against

noise.

Figure 4.3 Example of wiring for measures against noise

Terminal

block

Programmable

controller

AC

motor

Relay box

QD64D2

Cart

Encoder

Inverter

Terminal

block

Make the distance between the encoder and relay box as

short as possible.

If the distance is long, a voltage drop may occur. Therefore,

check that the voltages while the encoder is in

operation/stop are within the rated voltage at the terminal

block of the relay box using the measure such as a

synchronoscope.

Install I/O wires at least

150 mm (5.91 inch)

away from the high

voltage equipment such

as relay and inverter.

(Apply this wiring in a

control panel as well.)

Avoid using a solenoid valve and inductive load together in the same

metallic pipe. If a sufficient distance cannot be secured with high voltage

cable due to such as duct wiring, use CVVS or other shielded cable for the

high voltage cable.

Ground the shielded twisted pair cable on the QD64D2 side, and install

the cable as short as possible.