Rev. D

Multi Pro 5700--D Page 6 -- 11 Spray System

5. Remove lock nuts, flat washers, cap screws, and

coupler spacers that secure rubber coupling to pump

hub.

6. Remove four (4) flange head screws and flange nuts

that secure pump to pump mount bracket.

7. Remove pump from machine.

8. If needed, loosen set screws in pump hub. Pull hub

from pump shaft. Locate and remove key from pump

shaft. Remove set screws from pump hub. Clean

threads of set screws and hub.

9. If needed, remove pressure dampener, tee fitting

(pressure), and elbow fitting (pressure) from pump out-

let (Fig. 8).

10.If needed, remove suction dampener and tee fitting

(suction) from pump inlet (Fig. 8).

Installation (Fig. 6)

NOTE: Coat all spray system O--rings with vegetable

oil before installation to reduce the chance of damage

during assembly.

1. Apply PTFE tape to threads of removed tee fitting

(pressure), elbow fitting (pressure), and tee fitting (suc-

tion). Position new O--rings and gaskets on suction and

pressure fittings that wereremoved during disassembly.

2. If removed, install tee fitting (suction) and suction

dampener to pump inlet. Orientate tee toward rear of

machine (Fig. 8).

3. If removed, install elbow fitting (pressure), tee fitting

(pressure), and pressure dampener to pump outlet.

Orientate elbow toward rear of machine (Fig. 8).

4. If pump hub was removed, apply antiseize lubricant

to pump shaft. Install k ey in shaft and slide pump hub

onto shaft.

5. Position pump on pumpmounting bracketand install

flange head screws and flange nuts to pump and mount-

ing bracket. Leave fasteners loose.

6. Place coupling spacers into rubber coupling. Install

cap screws, flat washers, and locknuts to s ecure rubber

coupling to pump hub. Make sure that cap screw

threads extend through lock nut.

7. If pump hub was removed, apply Loctite #242 (or

equivalent) to threads of pump hub set screws. Install

set screws into pump hub to secure hub to pump shaft.

8. Turn pump shaft by hand and position pump on

mounting bracket to best align the coupling assembly

between the pump shaft and the hydraulic motor shaft.

9. Secure pump to mounting bracket by tightening

flange head screws and flange nuts.

10.Position front and rear guard plates to pump mount

bracket. Install and tighten flange head screw and

flange nut to guard plates. Install flange nuts to secure

guard plates to pump mount bracket.

11.Install pressure and suction hoses to correct barbfit-

tings (Fig. 7). Secure hoses with hose clamps.

1. Pressure hose 2. Suction hose

Figure 7

2

1

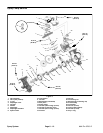

1. Spray pump

2. Pressure hose (1”)

3. Hose clamp

4. Hose barb

5. Nut

6. Gasket

7. Tee fitting (pressure)

8. Elbow fitting (pressure)

9. O--ring

10. Pressure dampener

11. Suction hose (1 1/2”)

12. Hose clamp

13. Nut

14. Seal

15. Tee fitting (suction)

16. Suction dampener

17. Hose barb

Figure 8

2

13

1

3

5

4

6

7

8

9

10

11

14

12

16

15

17

9

6

Spray

System