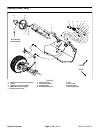

Removal (Fig. 38)

1. Park machine on a level surface, stop engine, en-

gage parking brake, and remove key from the ignition

switch.

CAUTION

Rotate steering wheel and depress traction ped-

al in both forward and reverse to relieve hydrau-

lic system pressure and to avoid injury from

pressurized hydraulic oil.

1

3

2

2. Operate all hydraulic controls to relieve hydraulic

system pressure.

3. Read the General Precautions for Removing and

Installing Hydraulic System Components at the begin-

ning of the Service and Repairs section of this chapter.

4. Label all hydraulic connections to ease reassembly.

Clean hydraulic hose ends prior to disconnecting the

hoses from PWM Valve.

5. Disconnect four (4) hydraulic hoses from fittings in

PWM Valve. Allow hoses to drain into a suitable contain-

er.

6. Put caps or plugs on disconnected hoses and fittings

to prevent contamination.

7. Disconnect PWM Valve solenoid connector from

machine wiring harness (Fig. 43).

8. Remove two (2) cap screws and flange nuts that se-

cure PWM Valve to pump mount bracket. Locate and re-

trieve two (2) flat washers from between PWM Valve and

pump mount bracket. Remove PWM Valve from ma-

chine.

Installation (Fig. 38)

1. Place two (2) cap screws into PWM Valve mounting

holes. Install flat washer on screws and position Valve

to pump mount bracket. Install and tighten flange nuts

to secure PWM Valve to bracket.

2. Remove caps and plugs from hydraulic hoses and

fittings. Lubricate new o–rings and install hydraulic

hoses to fittings in PWM Valve.

3. Plug PWM Valve solenoid connector into machine

wiring harness.

4. Check fluid level in hydraulic oil reservoir and adjust

as required (see Operator’s Manual).

5. Operate machine and inspect for leaks.

Figure 43

1. PWM Valve 3. Solenoid connector

2. Solenoid

3

1

2

4

Figure 44

1. IN port (from gear pump) 3. EX port (to oil cooler)

2. CF port (to motor) 4. Solenoid coil

Hydraulic

System

Multi Pro 5700–D Page 4 – 47 Hydraulic System