Rev. D

Multi Pro 5700--DPage 6 -- 26Spray System

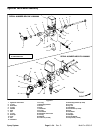

Boom and Agitation Valve Motor Service (Machines with Serial Numbers Below

310000000)

1. Housing cover

2. Cover seal

3. Valve motor

4. Phillips head screw

5. O--ring

6. Lock washer

7. Hand grip

8. Roller

9. Roller pin

10. Spindle

11. Spring

12. Spring seat

13. O--ring

14. Spindle housing

15. Phillips head screw (4 used)

16. O--ring

17. O--ring

18. Flat washer

19. Seat outer O--ring

20. Seat

21. Seat inner O--ring

22. Seat base

23. Flat washer

24. Spring

25. Flat washer

26. Cone

27. Screw

28. Manifold housing

29. Fork

30. O--ring

31. Balancing valve

32. Roll pin

33. Balancing valve knob

34. O--ring

35. Hosebarb

36. Nut

Figure 30

9

10

11

12

13

14

15

16

1

3

2

5

6

7

8

4

17

18

19

23

20

21

22

32

31

25

24

26

30

28

29

27

33

70 in--lb

(7.9 N--m)

34

35

36

A Multi Pro 5700--D sprayer with serial number below

310000000 uses three valve motor assemblies to con-

trol the spray booms andone valve motor to controltank

agitation (Fig. 31). Each of these motor assemblies in-

cludes a motor section (Items 1 through 7 in Figure 30),

a spindle section (Items 8 through 27 in Figure 30), and

a manifold assembly (Items 28 through 36 in Figure 30).

Disassembly and Inspection (Fig. 30)

IMPORTANT: Make sure to remove and neutralize

chemicals from spray components before disas-

sembly. Wear protective clothing, chemical resist-

ant gloves, and eye protection during repair.

1. Remove valve motor assembly from machine (see

Agitation Valve Motor Assembly or Boom Valve Motor

Assembly in this section).

2. To remove the motor and spindle section assembly

from the manifold assembly:

A. Remove the fork (item 29) that secures the motor

and spindle sections to the manifold assembly.

B. Lift the motor and spindle section assembly from

the manifold.

3. To allow easier separation of the motor and spindle

sections, make sure that valve motor is in the closed

position (green indicator is recessed into the spindle

housing). Remove four phillips head screws (item 15)

and separate spindle section from motor section.