Rev. D

Multi Pro 5700--DPage 6 -- 20Spray System

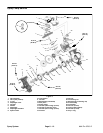

Spray Control Assembly

1. Boom valve motor assembly

2. O--ring

3. Flange nut

4. Flange nut

5. Flange head screw

6. Boom mounting bracket

7. Cross support angle

8. RH boom mount

9. Flange nut

10. Boom hold--in assembly

11. Valve mounting bar

12. LH boom mount

13. Flange head screw

14. R--clamp

15. Support bracket

16. Tee assembly

17. Agitation valve motor

18. O--ring

19. Hosebarb

20. Hose clamp

21. Agitation supply hose (1”)

22. Fork

23. Flange head screw

24. Flange head screw

25. Carriage bolt

26. Mount bracket

27. Boom bypass hose (1”)

28. Fork

29. Hose clamp

30. Boom supply hose (3 used)

31. Boom supply hose (1 1/2”)

32. Hose clamp

33. Hosebarb

34. Pressure gauge tube

35. Hosebarb

Figure 20

3

4

8

1

5

2

6

11

15

12

9

13

10

14

7

4

5

5

5

6

9

9

9

21

16

20

17

10

19

18

24

23

22

3

18

22

26

25

28

27

29

29

30

31

FRONT

RIGHT

32

20

33

34

35

SERIAL NUMBER BELOW 250999999 SHOWN

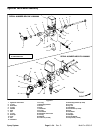

IMPORTANT: Make sure to remove and neutralize

chemicals from spray components before disas-

sembly. Wear protective clothing, chemical resist-

ant gloves, and eye protection during repair.

Removal (Fig. 20)

1. Park machine on a level surface, stop engine, en-

gage parking brake, and remove key from the ignition

switch.

2. On machines with serial number below 310000000,

remove two (2) flange head screws and flange nuts that

secure support bracket (item 15) to mount bracket (item

26). Position bracket away from spray control assembly.

3. Label hoses for proper installation after repairs are

completed (Fig. 21). Loosen hose clamps and discon-

nect hoses from spray control assembly as needed.