Multi Pro 5700--D Hydraulic SystemPage 4 -- 35

3. Operate all hydraulic controls to relieve hydraulic

system pressure.

4. Remove traction cableball joint from control plate on

piston pumpby removing lock nut (Fig.32). Remove cap

screw from control plate. Locate and retrieve three (3)

flat washers (Fig. 33).

5. Disconnect two (2) wires from neutral switch on pis-

ton pump (Fig. 32).

6. Remove flange head screw and flange nut that se-

cures R --clamp and right side brake cable to pump as-

sembly (Fig. 32).

7. Read the General Precautions for Removing and

Installing Hydraulic System Components at the begin-

ning of the Service and Repairs section of this chapter.

NOTE: To ease reassembly, tag hydraulic hoses to

show their correct position on the pump assembly.

8. Put a drain pan below the pump assembly. Remove

hydraulic hoses and fittings connected to piston and

gear pumps. Put plugs or capson disconnectedhydrau-

lic hoses to prevent contamination of the system. Put

plugs in open ports of pumps.

9. Support the pump assembly to prevent itfrom falling.

Remove two (2) cap screws, lock washers and flat

washers that retain pump assembly to engine bell hous-

ing.

10.Carefully pullpump assemblyfrom engineand lower

it out of the machine.

11.If needed, separate gear pump from piston pump

(see Gear Pump Removal in this section).

Installation (Fig. 31)

1. If gear pump was removed from piston pump, install

gear pump to piston pump (see Gear Pump Installation

in this section).

2. Apply antiseize lubricant to piston pump shaft

splines.

3. Carefully raise pump assembly and position it to the

engine. Make sure that both bushings on control plate

are between centering arms on rear of engine (Fig. 32).

4. Align spline teeth and slide piston pump input shaft

into engine coupling spline. Support pump to prevent it

from falling while installing two (2) cap screws, lock

washers and flat washers to secure pump to engine bell

housing.

5. Secure traction cableto control plate with capscrew,

three (3) washers and lock nut (Fig. 32 and 33).

6. Connect two (2) wires to neutral switch on piston

pump (Fig. 32).

7. Remove plugs or caps from disconnected hydraulic

hoses and ports of the pump assembly. Lubricate new

O--rings and install fittings and hoses to correct location

on gear and piston pumps.

8. Secure R--c lamp and right side brake cable to pump

assembly with flange head screw and flange nut.

9. Install new hydraulic oil filter and fill hydraulic reser-

voir with correct oil (see Operator’s Manual).

10.Properly fill hydraulic system (see Charge Hydraulic

System in the Service and Repairs section of this chap-

ter).

11.Stop engine and check for hydraulic oil leaks. Check

hydraulic reservoir oil level.

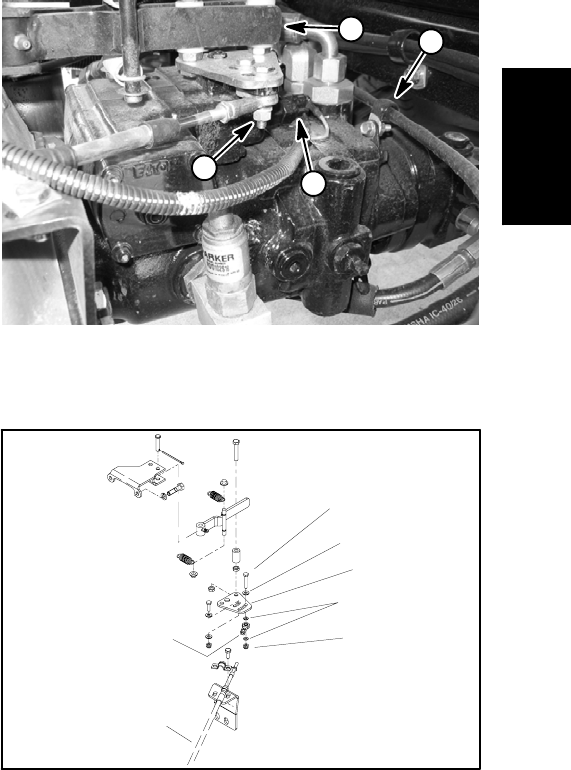

1. Traction cable lock nut

2. Neutral switch

3. R--clamp/brake cable

4. Centering arm

Figure 32

2

1

3

4

1. Cap screw

2. Flat washer

3. Neutral plate

4. Flat washer

5. Lock nut

6. Ball joint

7. Traction cable

Figure 33

3

5

4

2

1

6

7

Hydraulic

System