Multi Pro 5700–D Hydraulic SystemPage 4 – 45

Relief Valve

Removal

1. Park machine on a level surface, stop engine, en-

gage parking brake, and remove key from the ignition

switch.

CAUTION

Rotate steering wheel and depress traction ped-

al in both forward and reverse to relieve hydrau-

lic system pressure and to avoid injury from

pressurized hydraulic oil.

2. Operate all hydraulic controls to relieve hydraulic

system pressure.

3. Read the General Precautions for Removing and

Installing Hydraulic System Components at the begin-

ning of the Service and Repairs section of this chapter.

4. Disconnect hose assembly from hydraulic fitting at

bottom of relief valve body. Allow hose to drain into a

suitable container.

5. Unscrew relief valve body from hydraulic adapter in

side of piston pump.

6. If needed, remove hydraulic fitting from bottom of re-

lief valve body.

Installation

1. Lubricate new o–rings with clean hydraulic fluid.

2. If removed, install hydraulic fitting into bottom of re-

lief valve body.

3. Secure valve body to the hydraulic adapter in side of

piston pump.

4. Install hydraulic hose to hydraulic fitting at bottom of

relief valve body. Tighten hose connections.

Disassembly

1. Unscrew relief valve cartridge from the relief valve

body. Remove o–ring and back–up ring.

2. Inspect ports of the relief valve body for damaged

sealing surfaces or threads and contamination.

3. Inspect relief valve cartridge for damaged sealing

surfaces and contamination.

A. Contamination may cause valves to stick or hang

up. Contamination can become lodged in small valve

orifices or seal areas causing malfunction.

B. If sealing surfaces appear pitted or damaged, the

hydraulic system may be over heating or there may

be water in the hydraulic system.

CAUTION

Use eye protection such as goggles when using

compressed air.

4. Clean relief valve cartridge using clean mineral spir-

its to flush out any contamination. Submerge cartridge

in clean mineral spirits to flush out contamination. Par-

ticles as fine as talcum powder can affect the operation

of relief valve. Use compressed air for cleaning.

Reassembly

1. Lubricate new o–ring and back–up ring with clean

hydraulic fluid. Install o–ring and back–up ring to the re-

lief valve cartridge.

2. Carefully thread relief valve cartridge into the relief

valve body. The valve should go in easily without bind-

ing. Torque cartridge to 190 in–lb (21.4 N–m).

3. Lubricate new O–rings with clean hydraulic fluid.

Connect hydraulic fittings and O–rings to the relief valve

body.

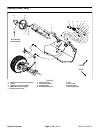

1. Pump assembly

2. O–ring

3. Hydraulic adapter

4. O–ring

5. Relief valve body

6. Relief cartridge

7. Seal kit

8. Hydraulic fitting

9. O–ring

10. Hydraulic hose

Figure 41

2

7

8

9

5

6

3

1

10

4

190 in–lb

(21.5 N–m)

Hydraulic

System