3. Install three (3) shorter (30 mm) and two (2) longer

(55 mm) bolts into pump casing assembly (Fig. 11).

Thread hex nuts onto bolts but do not fully tighten.

Check that crankshaft turns freely.

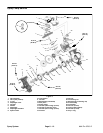

4. Place diaphragm back disc and new diaphragm onto

each connecting rod. The connecting rods should ex

-

tend above the diaphragms when correctly installed

(Fig. 12). Position nylon washer and washer on each

connecting rod and then thread hex bolt into connecting

rod. Torque bolt to 60 ft–lb (80 N–m).

5. Make sure that pump casings align and then secure

pump casing assembly by torquing five (5) bolts to 32 ft–

lb (44 N–m).

6. Secure diaphragm covers to pump using hex bolts (4

per cover). Torque bolts to 55 ft–lb (75 N–m).

7. Place new o–rings and valves into diaphragm cover

openings (Fig. 13). Inlet valves should be installed with

the spring down into the cover. Outlet valves should be

installed in with the spring up and away from cover.

8. Place valve chamber over valves noting orientation

of chamber inlet and outlet. Secure valve chamber with

two (2) hex bolts. Torque bolts 60 ft–lb (80 N–m).

2

1

Figure 12

1. Diaphragm 2. Connecting rod

2

2

1

3

Figure 13

1. Inlet (suction) 3. Outlet valve

2. Inlet valve

Spray System

Page 6 – 14

Multi Pro 5700–D