CAUTION

The centering springs are under tension. Re-

move the retaining ring carefully.

10.Remove the spring retaining ring and centering

springs from the spool.

Reassembly

Check all mating surfaces. Replace any parts with

scratches or burrs that could cause leakage. Wash all

metal parts in clean solvent. Blow them dry with pressur-

ized air. Do not wipe parts dry with paper towels or cloth.

Lint in a hydraulic system will cause damage.

NOTE: Always use new seals and o–rings when

reassembling the steering control valve.

IMPORTANT: During reassembly, lubricate the new

seals with petroleum jelly. Also, lubricate machined

surfaces and bearings with clean hydraulic oil.

1. Install the quad seal:

A. Put one of the bearing races and sleeve into the

housing.

B. Together, the housing and bearing race create a

groove into which the quad seal will be installed.

C. Hold the bearing race tightly against the input end

of the housing by pushing on the gerotor end of the

sleeve.

D. Fit the quad seal into its seat through the input

end of the housing. Be sure the seal is not twisted.

E. Remove the sleeve and bearing race.

2. Lubricate and install the dust seal.

3. Install the centering springs in the spool. It is best to

install the two flat pieces first. Next, install the curved

pieces, three at a time.

4. Fit the retaining ring over the centering springs.

5. Apply a light coating of clean hydraulic oil to the spool

and slide it into the sleeve. Be sure the centering springs

fit into the notches in the sleeve.

6. Install the pin.

7. Apply a light coating of petroleum jelly to the inner

edge of the dust and quad seals.

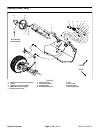

8. Put the thrust bearing and bearing races into the

housing. The thrust bearing goes between the two bear-

ing races (Fig. 49).

IMPORTANT: Do not damage the dust or quad seals

when installing the spool and sleeve assembly.

9. Apply a light coating of clean hydraulic oil to the spool

and sleeve assembly. Carefully slide the assembly into

the housing.

10.Clamp the housing in a vise. Use only enough clamp-

ing force to hold the housing securely.

11. Lubricate and install a new o-ring (Item 3) in the

groove in the housing.

12.Install the wear plate and align screw holes in the

wear plate with threaded holes in the housing.

NOTE: The holes in the wear plate are symmetrical.

13.Install the geroter drive, making sure the slot in the

drive engages the pin.

14.Lubricate and install new o-ring in wear plate groove.

15.Install the gerotor and align the screw holes.

16.Lubricate and install new o-ring in gerotor ring

groove.

17.Lubricate and install new o-ring and seal ring in gero-

tor star groove.

18.Install the spacer.

19.Install the end cap and seven (7) cap screws. Tighten

the cap screws, in a crossing pattern, from 140 to 160

in-lb (15.8 to 18.1 N–m).

20.Remove the steering control unit from the vise.

21.Install the check ball and plug with o–ring. Tighten

the plug to 150 in-lb (17 N–m).

Thrust Bearing

and Race (2)

Quad Seal

Dust Seal

Figure 49

Hydraulic

System

Multi Pro 5700–D Page 4 – 51 Hydraulic System