Multi Pro 5700--D Hydraulic SystemPage 4 -- 43

Removal (Fig. 40)

1. Park machine on a level surface, stop engine, en-

gage parking brake, and remove key from the ignition

switch.

CAUTION

Rotate steering wheeland depress traction ped-

al in both forward and reverse to relieve hydrau-

lic system pressure and to avoid injury from

pressurized hydraulic oil.

2. Operate all hydraulic controls to relieve hydraulic

system pressure.

3. Read the General Precautions for Removing and

Installing Hydraulic System Components at the begin-

ning of the Service and Repairs section of this chapter.

4. Remove flange head screw and flange nut that se-

cure front and rear guard plate. Remove four (4) flange

nuts thatretain guard plates to pumpmount bracket. Re-

move guard plates from machine.

5. Label all hydraulic connections to ease reassembly.

Clean hydraulic hose ends prior to disconnecting the

hoses from hydraulic motor.

6. Disconnect hydraulic hoses frommotor. Allowhoses

to drain into a suitable container.

7. Put caps or plugson disconnectedhoses andfittings

to prevent contamination.

8. Remove lock nuts, flat washers, cap screws, and

coupler spacersthat securerubber couplingto hydraulic

motor hub.

9. Remove two (2) flange head screws and flange nuts

that secure hydraulic motor to pump mount bracket.

10.Remove hydraulic motor from machine.

11.If needed, loosen set screws in hydraulic motor hub.

Pull hub from motor shaft. Locate and remove woodruff

key from motor shaft. Remove set screws from hub.

Clean threads of set screws and hub.

12.If hydraulic fittingremoval is needed, note orientation

of hydraulic fittings before removing fittings from motor.

Installation (Fig. 40)

1. Ifremoved, lubricate newO--rings and installhydrau-

lic fittings to motor.

2. If motor hub was removed, apply antiseize lubricant

to motor shaft. Install woodruff key in shaft and slidehub

onto motor shaft.

3. Position motor on pump mounting bracket andinstall

flange head screws and flange nuts to motor and mount-

ing bracket. Leave fasteners loose.

4. Place coupling spacers into rubber coupling. Install

cap screws, flat washers, and locknuts to s ecure rubber

coupling to motor hub. Make sure that cap screw

threads extend through lock nut.

5. If motor hub was removed, apply Loctite #242 (or

equivalent) to threads of motor hub set screws. Install

set screws into hub to secure hub to motor shaft.

6. Turn pump shaft by hand and position motor on

mounting bracket to best align the coupling assembly

between the pump shaft and the hydraulic motor shaft.

7. Secure motor to mounting bracket by tightening

flange head screws and flange nuts.

8. Lubricate new O--rings and install hydraulic hoses to

correct hydraulic fittings on motor.

9. Position front and rear guard plates to pump mount

bracket. Install and tighten flange head screw and

flange nut to guard plates. Install flange nuts to secure

guard plates to pump mount bracket.

10.Check fluid level in hydraulic oil reservoir and adjust

as required (see Operator’s Manual).

11.Properly fill hydraulic system (see Charge Hydraulic

System in the Service and Repairs section of this chap-

ter).

12.Stop engine and check for hydraulic oil leaks. Check

hydraulic reservoir oil level.

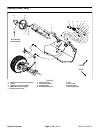

1. Spray pump drive motor

2. Hydraulic hose (from PWM CF port)

3. Hydraulic hose (to PWM EX port)

Figure 41

3

2

1

Hydraulic

System