Multi Pro 5700–DChassis

Page 7 – 10

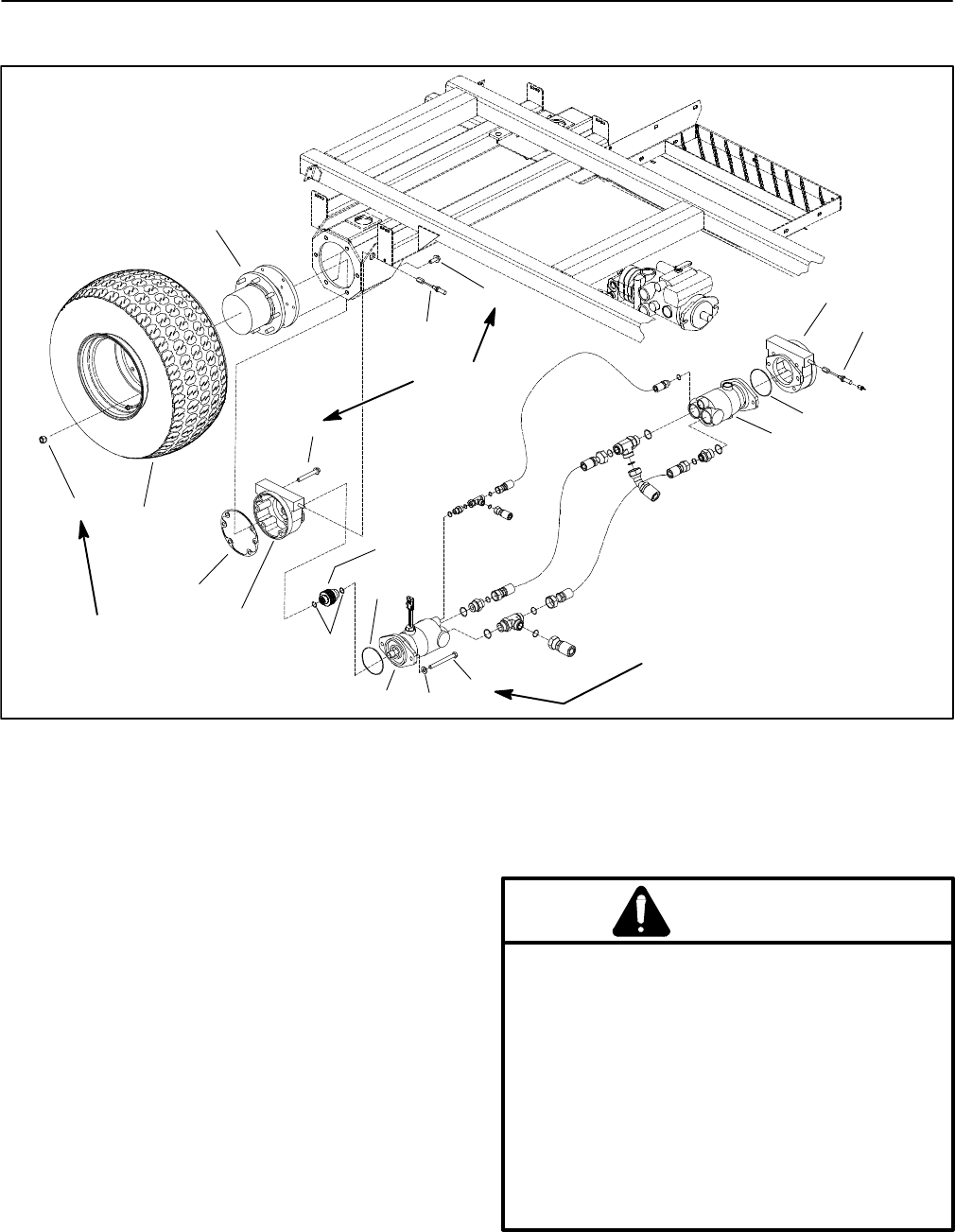

Brake Assembly

1. RH brake cable

2. Planetary assembly

3. Lug nut (8 used per wheel)

4. Tire and wheel assembly

5. Gasket

6. RH brake assembl

y

7. Flange head screw (4 used per brake)

8. Splined brake shaft

9. Retaining ring

10. O–ring

11. RH wheel motor

12. Flat washer (2 used per motor)

13. Cap screw (2 used per motor)

14. LH wheel motor

15. LH brake cable

16. LH brake assembly

17. Flange head screw (6 used per side)

Figure 6

70 to 90 ft–lb

(95 to 122 N–m)

60 ft–lb

(81 N–m)

1

2

3

4

5

12

13

14

15

16

6

7

8

9

10

11

10

17

60 ft–lb

(81 N–m)

Removal (Fig. 6)

1. Park machine on a level surface, stop engine, en-

gage parking brake, and remove key from the ignition

switch.

2. Drain oil from planetary wheel drive/brake assembly

(see Operator’s Manual).

CAUTION

When changing attachments, tires, or perform-

ing other service, use correct blocks, hoists,

and jacks. Make sure machine is parked on a

solid, level surface such as a concrete floor.

Prior to raising machine, remove any attach-

ments that may interfere with the safe and

proper raising of the machine. Always chock or

block wheels. Use jack stands or solid wood

blocks to support the raised machine. If the ma-

chine is not properly supported by blocks or

jack stands, the machine may move or fall,

which may result in personal injury.