206

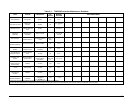

Table 6-1: T200H/M Preventive Maintenance Schedule

ITEM ACTION FREQUENCY

CAL

CHECK

MANUAL

SECTION

DATE PERFORMED

1

Particulate Filter Change filter Weekly

No 9.3.1

Verify Test Functions

Review and

evaluate

Weekly No

9.2; Appendix

C

Zero/Span Check

Evaluate offset and

slope

Weekly -- 7.3, 7.5, 7.7

1

Zero/Span

Calibration

Zero and span

calibration

Every 3 months

--

7.2, 7.4, 7.6,

7.7, 7,8

NO

2

Converter

Replace converter

& check efficiency

Every 3 years or if

conversion efficiency

< 96%

Yes if CE

factor is

used

--

1

External Zero Air

Scrubber (Optional)

Exchange chemical Every 3 months No 3.5.3.2

1

Reaction Cell

Window

Clean optics,

Change O-rings

Annually or as

necessary

Yes 6.3.5

1

Air Inlet Filter Of

Perma Pure Dryer

Change particle

filter

Annually No 6.3.2

Pneumatic Sub-

System

Check for leaks in

gas flow paths

Annually or after

repairs involving

pneumatics

Yes on

leaks, else

no

7.5.1, 7.5.2

1

All Critical Flow

Orifice O-Rings &

Sintered Filters

Replace Annually Yes 6.3.6

1, 2

Pump Rebuild head Annually Yes 9.3.4

Inline Exhaust

Scrubber

Replace Annually No

Pmt Sensor

Hardware Calibration

Low-level hardware

calibration

On PMT/ preamp

changes & if

0.7< SLOPE >1.3

Yes 11.6.5

1

These Items are required to maintain full warranty, all other items are strongly recommended.

2

A pump rebuild kit is available from Teledyne API Technical Support including all instructions and required parts (the pump part number is on the label of the pump itself).

07270B DCN6512