Teledyne API - Model T200H/T200M Operation Manual Principles of Operation

275

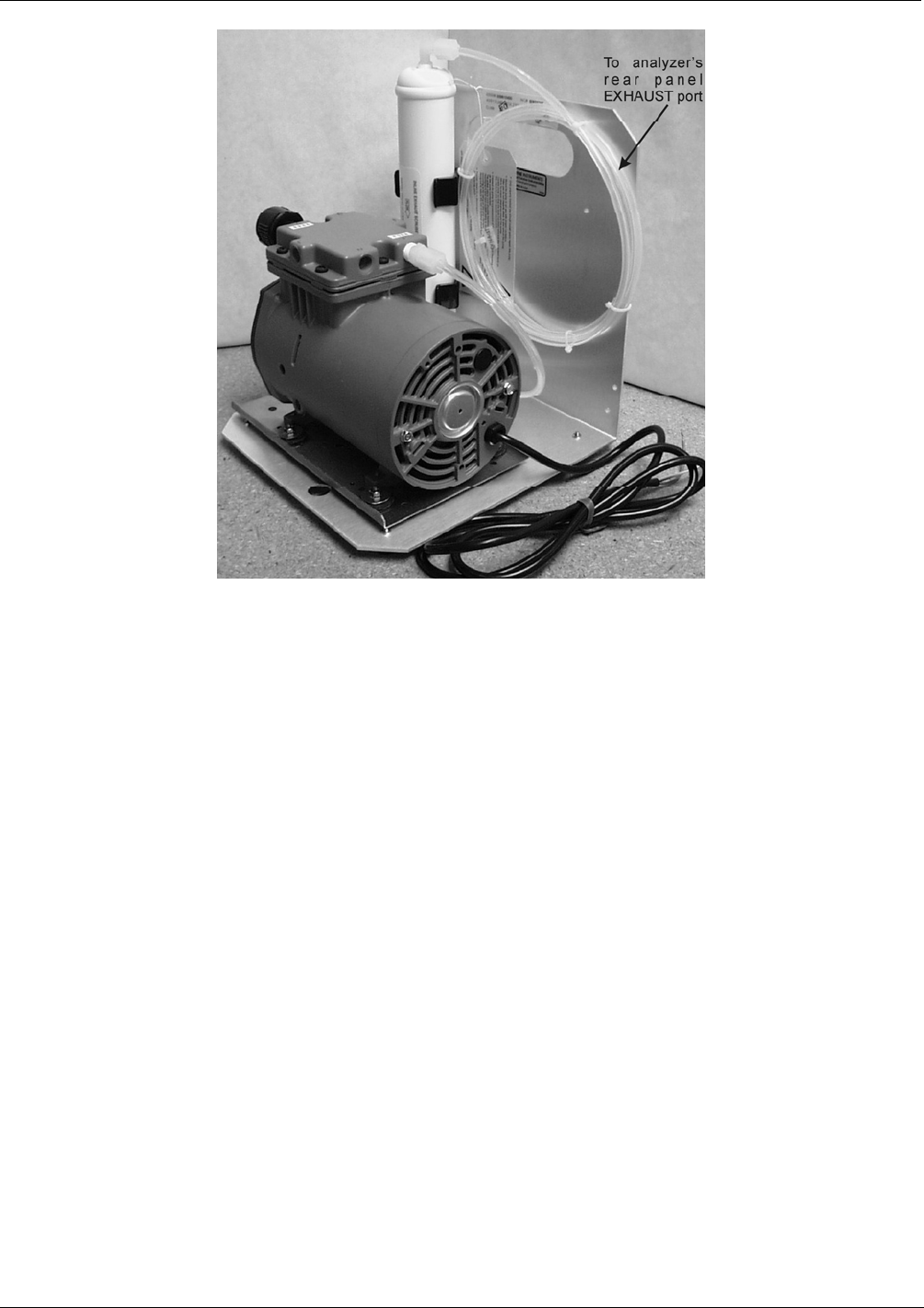

Figure 8-5: External Pump Pack

Finally, the T200H/M requires a steady, high under-pressure, which cannot be achieved

reliably over extended periods of time with small vacuum pumps. The external pump

used for the T200H/M has a very long lifetime and duty cycle and provides a very good

vacuum for its entire lifetime. However, the pump is too large to fit into the chassis of

the analyzer.

8.3.2. SAMPLE GAS FLOW

The sample gas is the most critical flow path in the analyzer, as the medium has to be

routed through a variety of valves and tubes for the measurement of zero offset and

concentrations of both NO and NO

X

(and possibly the drying of the gas if the optional

sample dryer is installed). At any point before and in the reaction cell, the integrity of

the sample gas cannot be compromised.

Sample gas flow in the T200H/M analyzer is not a directly measured value, but is rather

calculated from the sample pressure using the flow principle across a critical orifice. In

general, the differential pressure ratio between sample pressure and reaction cell

pressure needs to exceed 2:1 to allow critical flow. The actual flow rate is then only

dependent on the size of the orifice and the upstream pressure. Refer to Section 8.3.3

for a detailed description of

the instrument’s method of gas flow rate control.

07270B DCN6512