Principles of Operation Teledyne API - Model T200H/T200M Operation Manual

290

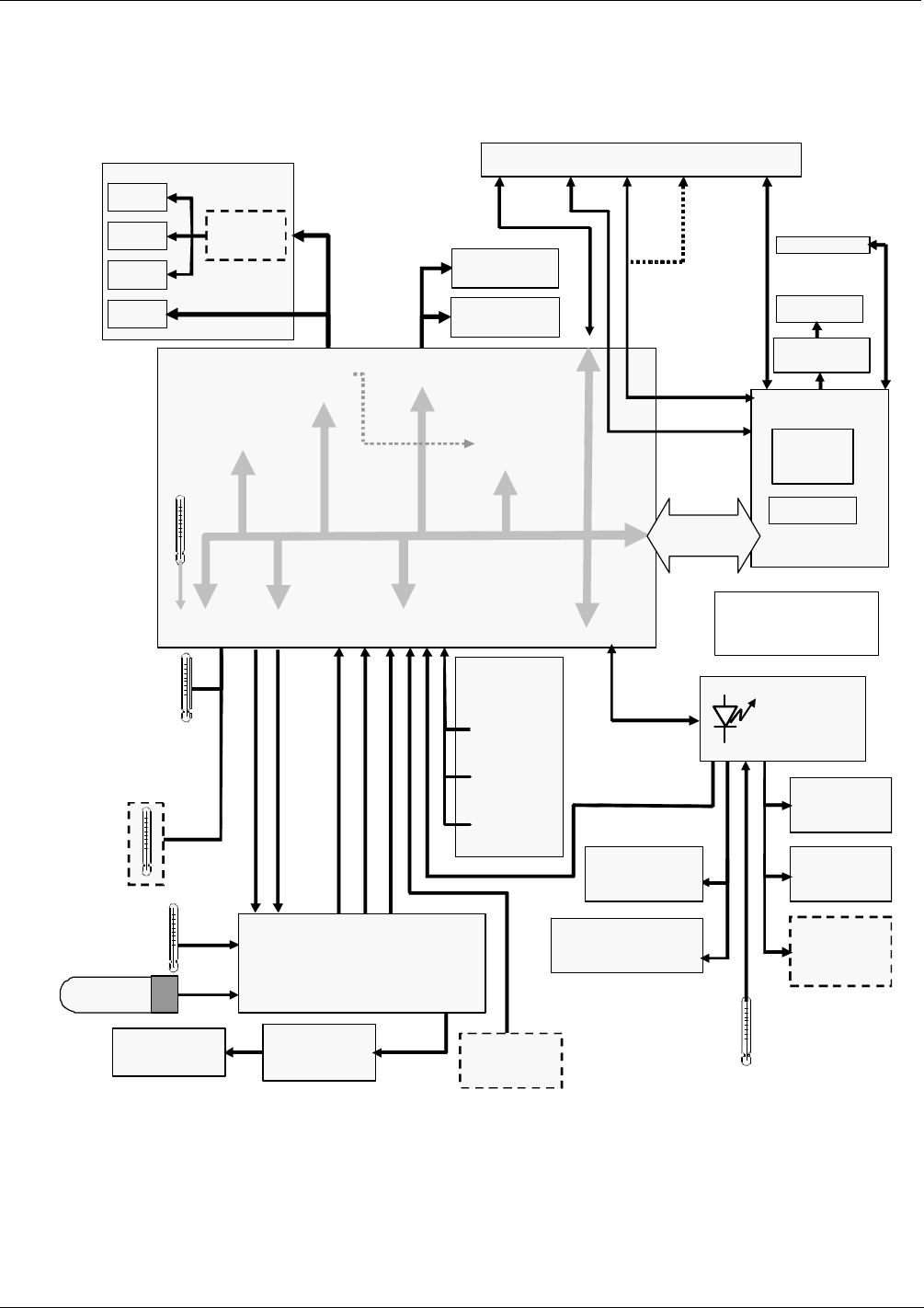

8.5. ELECTRONIC OPERATION

Figure 8-15 shows a block diagram of the major electronic components of the T200H/M.

Pneumatic

Sensor

Board

Sample

Pressure

Sensor

Vacuum

Pressure

Sensor

O

3

Flow Sensor

Analog Outputs

Status Outputs:

1 – 8

Control Inputs:

1 – 6

PC 104

CPU Card

Disk On

Module

Flash Chip

COM1 (RS–232 ONLY)

COM2 (RS–232 or RS–485)

Power-Up

Circuit

I

2

C Bus

Analog

Sensor Inputs

Box

Temp

Thermistor

Interface

REACTION CELL

TEMPERATURE

MOLYBDENUM CONVERTER

TEMPERATURE

PMT

Temperature

Sensor

A1

A2

A3

Optional

4-20 mA

MOTHER

BOARD

A/D

Converter(

V/F)

PC 104

Bus

External

Digital I/O)

Analog

Outputs

(D/A)

RELAY

BOARD

I

2

C Status

LED

PUMP

(Externally Powered)

A4

CPU

S

tatus

LED

NO/NO

x

Valve

Autozero

Valve

Sample Cal

Valve Option

Option

Reaction Cell

Heater

Molybdenum

Converter Heater

PMT TEC

PMT

MOLYBDENUM CONVERTER

TEMPERATURE SIGNAL

TEC Drive

PCA

Internal

Digital I/O

ELECTRIC TEST CONTROL

OPTIC TEST CONTROL

PMT OUTPUT (PMT DET)

O

2

Sensor

Option

HIGH VOLTAGE POWER SUPPLY LEVEL

PMT TEMPERATURE

PMT

PREAMP PCA

O

2

OPTION

TEMPERATURE

Display

Touchscreen

LVDS

transmitter board

Analog RS232 COM2 USB Ethernet

IN

Male Female COM port

USB

or USB

(I

2

C Bus)

Figure 8-15: T200H/M Electronic Block Diagram

The core of the analyzer is a microcomputer (CPU) that controls various internal

processes, interprets data, calculates data, and reports results using specialized firmware

developed by Teledyne API. It communicates with the user, receives data from and

issues commands to a variety of peripheral devices through the motherboard, the main

printed circuit assembly on the rear panel.

07270B DCN6512