Teledyne API – Model T700 Dynamic Dilution Calibrator Maintenance

227

8.2. MAINTENANCE PROCEDURES

The following procedures are to be performed periodically as part of the standard

maintenance of the T700 calibrator.

8.2.1. AUTO LEAK CHECK

8.2.1.1. Equipment Required

Four (4) 1/4" Pneumatic caps.

One (1) 1/8” Pneumatic Cap

One (1) # 6 hexagonal Driver/Wrench

One (1) Pneumatic “T” fitting

8.2.1.2. Setup Auto Leak Check

To perform a leak-check on the T700 calibrator:

1. Remove the cover from the calibrator.

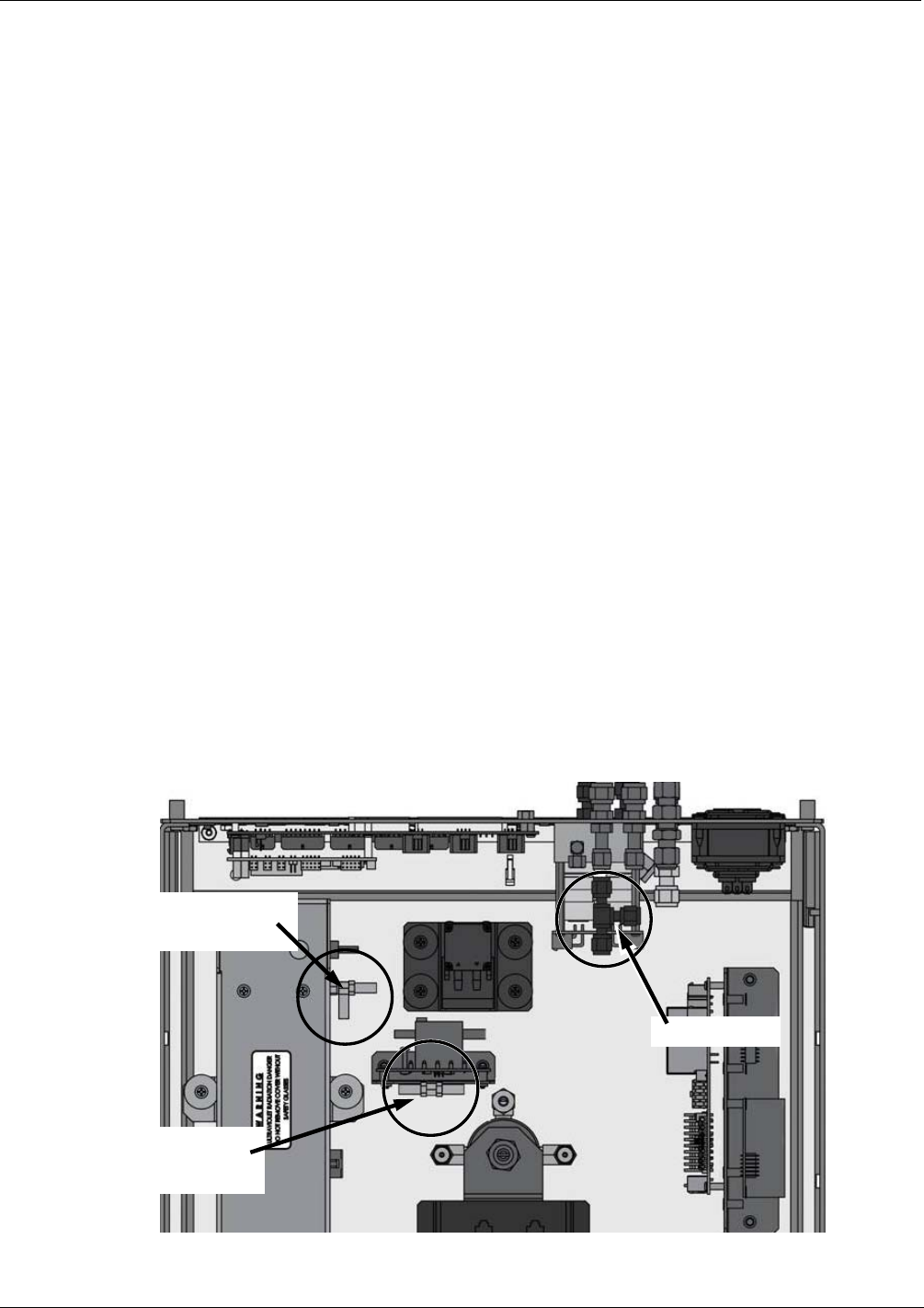

2. On Instruments with the optional O3 photometer installed, the photometer flow

sensor PCA and pump must be bypassed:

Using a #6 nut driver, remove the hexagonal nut located at the top of the gas

outlet of the photometer (see Figure 8-1).

Usi

ng a #6 nut driver, remove the hexagonal nut located on the fitting on the

back side of the Flow/Pressure sensor board (see Figure 8-1).

Con

nect the end of the line removed from the Sensor PCA in Step 3 to the

Photometer Outlet Fitting.

Photometer Gas

Outlet Fitting

Photometer

Flow Sensor / Pump

Outlet Fitting

Internal Vent

Figure 8-1: Bypassing the Photometer Sensor PCA and Pump

06873B DCN6388