Teledyne API – Model T700 Dynamic Dilution Calibrator Principles of Operation

285

WARNING

NEVER REMOVE THIS SAFETY SHIELD WHILE THE INSTRUMENT IS PLUGGED

IN AND TURNED ON. THE CONTACTS OF THE AC RELAY SOCKETS BENEATH

THE SHIELD CARRY HIGH AC VOLTAGES EVEN WHEN NO RELAYS ARE

PRESENT

10.3.3.1. Valve Control

The relay PCA also hosts two valve driver chips, each of which can drive up four valves.

In the T700, the relay PCA controls only those valves associated with the O

3

generator

and photometer options. All valves related to source gas and diluent gas flow are

controlled by a separate valve driver PCA (see Section 10.3.4).

10.3.3.2. Heater Control

The relay PCA controls the various DC heaters related to the O

3

generator and

photometer options.

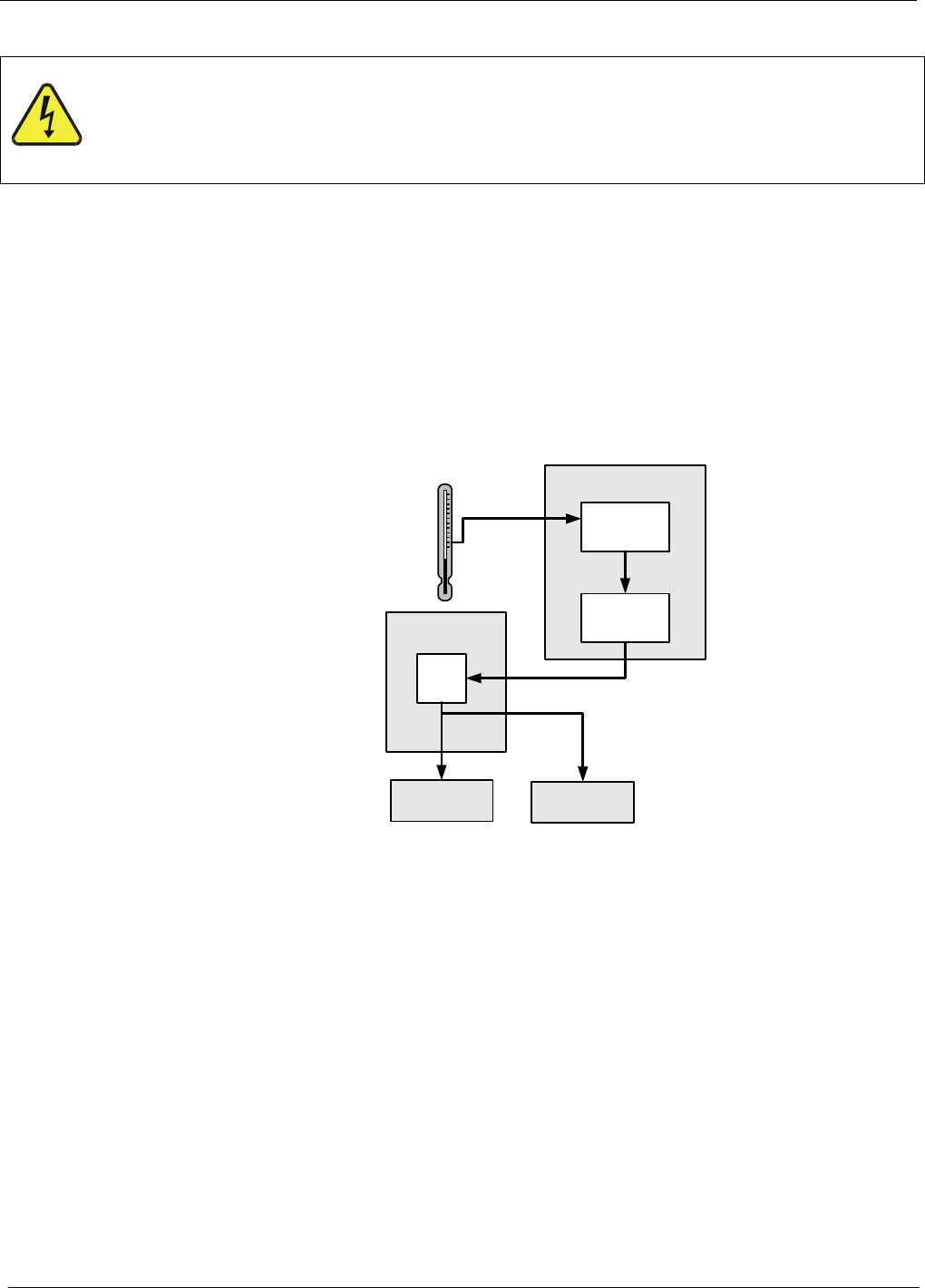

Thermistor(s)

(e.g. photometer sample gas temp.;

photometer UV lamp temp.; O

3

generator

lamp temp.; ect.)

RELAY PCA

DC

Control

Logic

MOTHERBOARD

A/D

Converter

(V/F)

CPU

O

3

Generator

Lamp Heater

PHOTOMETER

Lamp Heater

Figure 10-6: Heater Control Loop Block Diagram.

10.3.3.3. Relay PCA Status LEDs & Watch Dog Circuitry

Thirteen LEDs are located on the calibrator’s relay PCA to indicate the status of the

calibrator’s heating zones and some of its valves as well as a general operating watchdog

indicator. Table 10-1 shows the status of these LEDs and their respective functionality.

06873B DCN6388