Principles of Operation Teledyne API – Model T700 Dynamic Dilution Calibrator

294

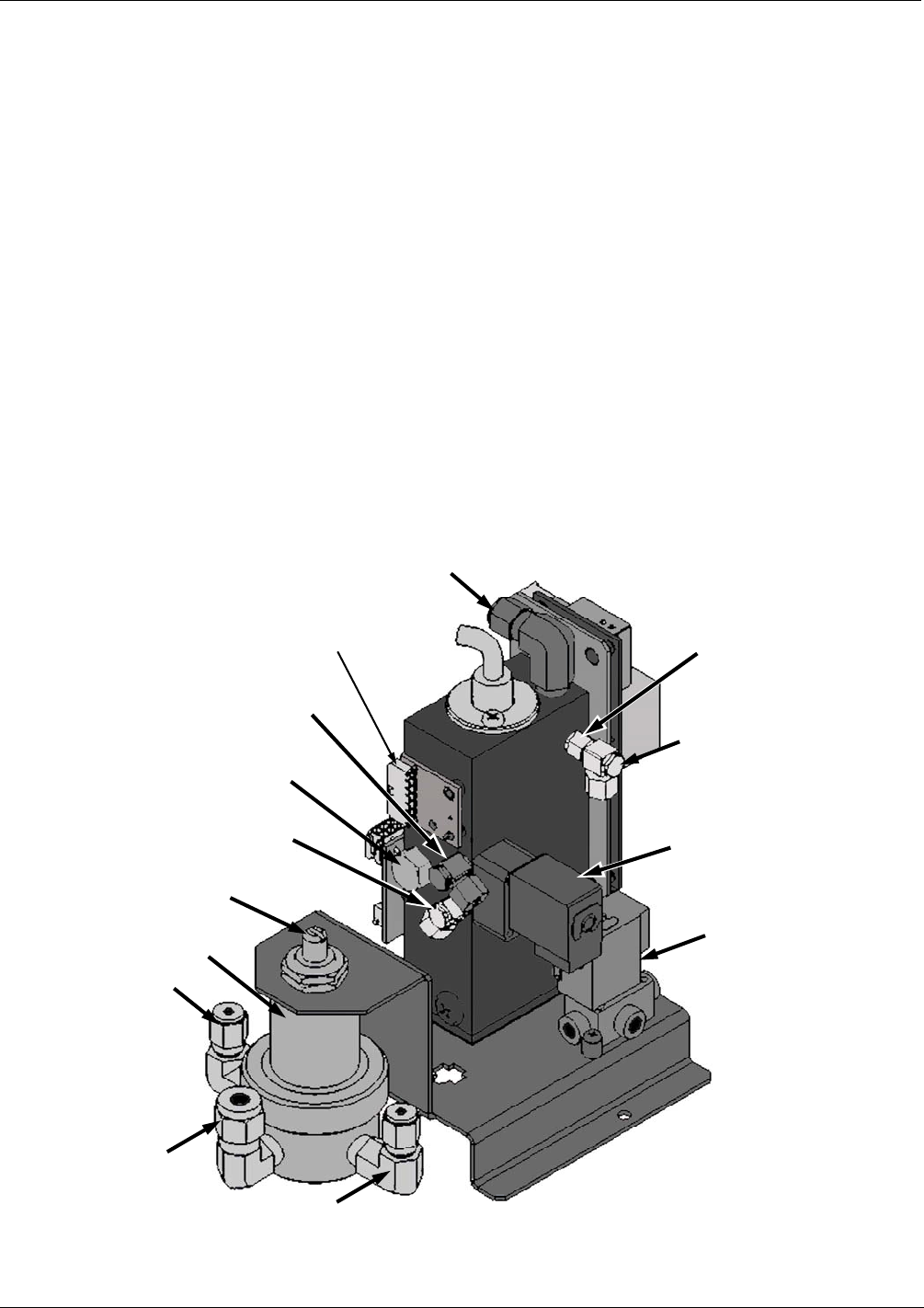

10.6.2. O3 GENERATOR – PNEUMATIC OPERATION

Pneumatic flow through the O

3

generator is created by supplying zero air (diluent) to it

under pressure. The zero air source must be capable of maintaining a continuous flow

rate of at least 100 cm

3

/min unless the optional photometer is also installed, in which

case the minimum continuous flow rate must be at least 1.1 LPM.

Input and output gas flow is directed by two valves, both of which must be open:

The diluent inlet valve: This valve is located on the back panel and allows diluent /

zero air into the calibrator.

The O

3

generation valve: This valve is located on the body of the O

3

generator is

downstream from the generator chamber itself and directs the output of the

generator to either the GPT mixing chamber or the exhaust vent at the back of the

calibrator.

The rate of flow through the O

3

generator is controlled by a 100 cm

3

/min flow control

assembly positioned between the O

3

generation chamber and the O

3

generation valve. A

self adjusting pressure regulator on the zero air (diluent ) supply gas line maintains the

pressure across the critical flow orifice of the flow control assembly (see Section

10.2.1.3).

O

3

Generator Zero Air

Pressure Regulator

Regulator Adjustment

Screw

Regulator

Gas Inlet

Outlet to O

3

Generator

Pressure

Sensor

Outlet from Regulator

to O

3

Generator

O

3

Generation

Valve

Measure / Reference

Valve for

Photometer Bench

(only present when

photometer option is

installed)

O

3

Outlet to

Photometer

“Zero Out” fixture

and Internal Vent

Photometer/Vent

Flow Control Assembly

(1.0 LPM)

O

3

Generator

Gas Inlet

O

3

Outlet to

GPT Valve

O

3

Outlet to Exhaust Fixture

(on back panel of calibrator)

O

3

Generator

Heater Control PCA

O

3

Generation Valve

Flow Control Assembly

(100 cm

3

/min)

Figure 10-13: O

3

Generator Valve and Gas Fixture Locations

06873B DCN6388