Troubleshooting and Service Teledyne API – Model T700 Dynamic Dilution Calibrator

244

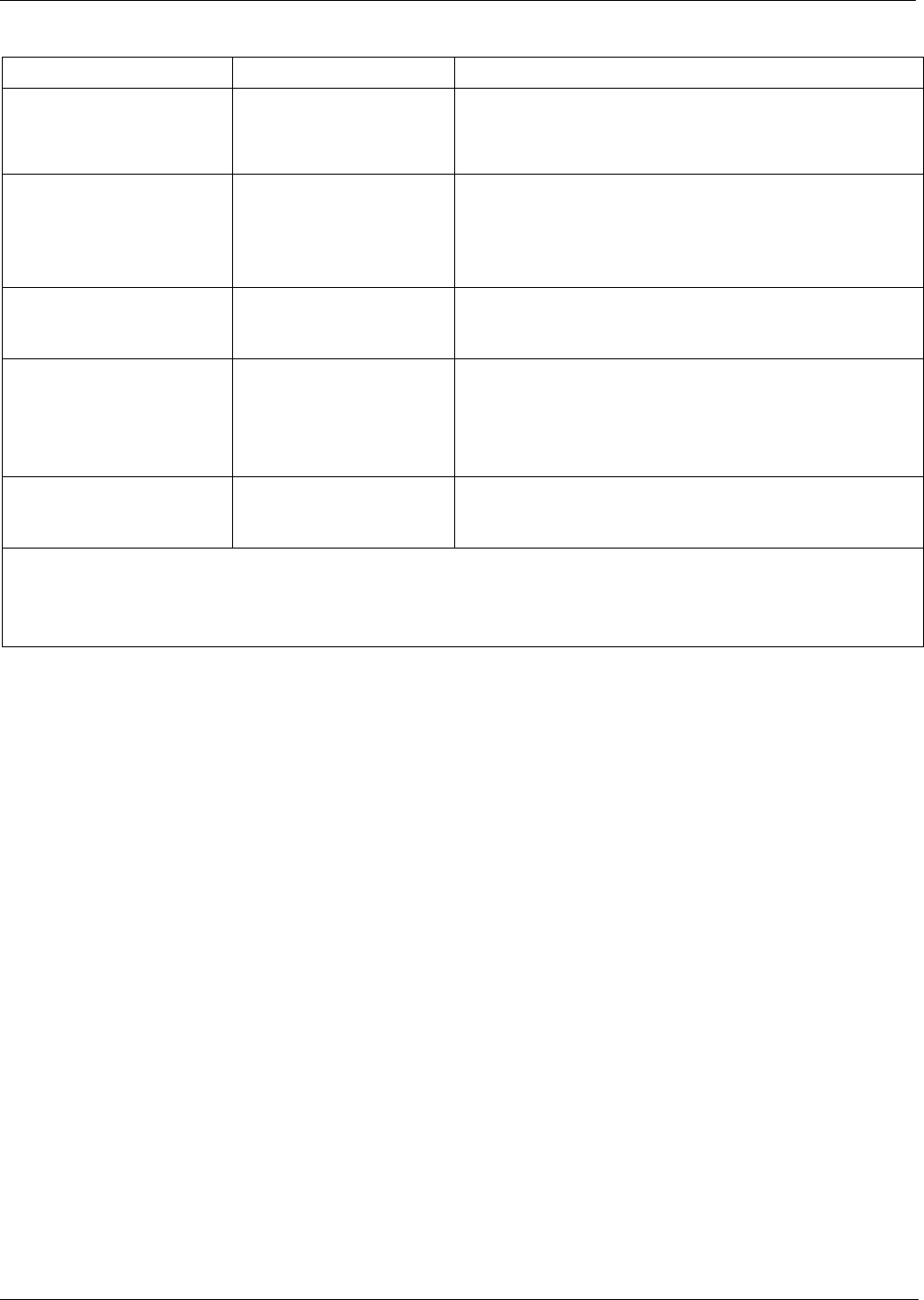

WARNING FAULT CONDITION POSSIBLE CAUSES

REAR BOARD NOT DET

Mother Board not detected

on power up.

- THIS WARNING only appears on Serial I/O COMM

Port(s) Front Panel Display will be frozen, blank or will not

respond.

- Failure of Mother Board

REGULATOR PRESSURE

WARNING

Regulator pressure is

< 15 PSIG or > 25 PSIG.

- Zero or source air supply is incorrectly set up or

improperly vented.

- Incorrectly adjusted O

3

zero air pressure regulator

- Leak or blockage exists in the T700’s internal pneumatics

- Failed O

3

Generator Input pressure sensor

RELAY BOARD WARN

The CPU cannot

communicate with the

Relay PCA.

- I

2

C Bus failure

- Failed relay PCA

- Loose connectors/wiring

SYSTEM RESET

The computer has

rebooted.

- This message occurs at power on.

- If it is confirmed that power has not been interrupted

- Failed +5 VDC power

- Fatal error caused software to restart

- Loose connector/wiring

VALVE BOARD WARN

The CPU is unable to

communicate with the valve

board.

- I

2

C Bus failure

- Failed valve driver PCA

- Loose connectors/wiring

1

Only applicable for calibrators with the optional the O

3

generator installed.

2

Only applicable for calibrators with the optional photometer installed.

3

On instrument with multiple Cal Gas MFCs installed, the MFC FLOW WARNING occurs when the flow rate requested is

<10% of the range of the lowest rated MFC (i.e. all of the cal gas MFC are turned off).

9.1.2. FAULT DIAGNOSIS WITH TEST FUNCTIONS

Besides being useful as predictive diagnostic tools, the test functions viewable from the

calibrator’s front panel can be used to isolate and identify many operational problems

when combined with a thorough understanding of the calibrators Theory of Operation

(see Section 10).

The acceptable ranges

for these test functions are listed in the “Nominal Range” column

of the calibrator Final Test and Validation Data Sheet shipped with the instrument.

Values outside these acceptable ranges indicate a failure of one or more of the

calibrator’s subsystems. Functions whose values are still within acceptable ranges but

have significantly changed from the measurement recorded on the factory data sheet

may also indicate a failure.

A worksheet has been provided in Appendix C to assist in recording the values of these

Test Functions.

Table 9-2 contains some of the more common causes for these values to be out of range.

06873B DCN6388