5 - 2

MELSEC-Q

5 DATA USED FOR POSITIONING CONTROL

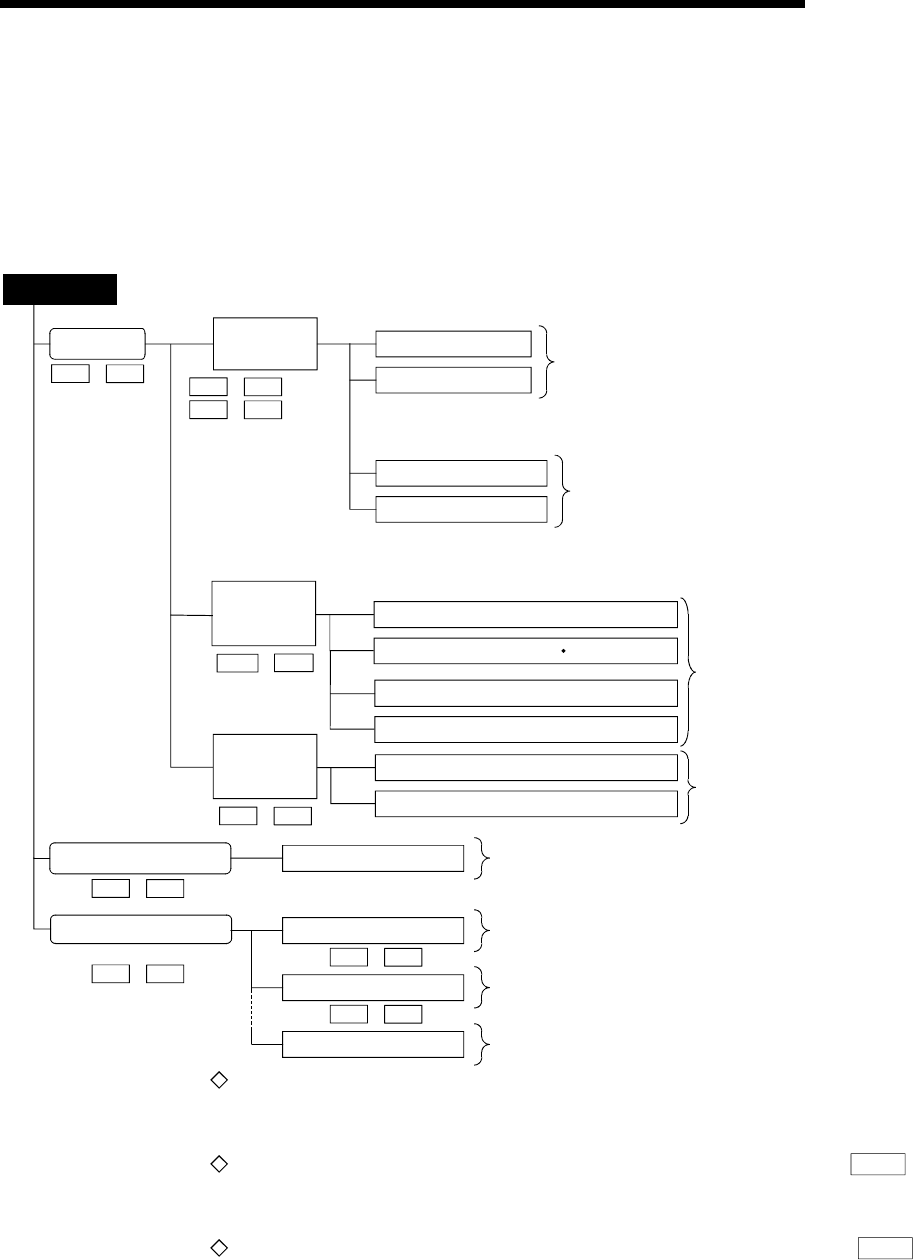

5.1 Types of data

5.1.1 Parameters and data required for control

The parameters and data required to carry out control with the QD75MH include the

"setting data", "monitor data" and "control data" shown below.

Setting data

(Data set beforehand according to the machine and application, and stored in the flash ROM.)

Parameters

Positioning

parameters

Basic parameters 1

Set according to the machine and applicable

motor when system is started up.

Note)

If the setting of the basic parameters 1 is incorrect, the rotation direction

may be reversed, or no operation may take place.

Basic parameters 2

Detailed parameters 1

Detailed parameters 2

Set according to the system configuration when

the system is started up.

Note)

Detailed parameters 2 are data items for using the QD75MH functions to the fullest.

Set as required.

OPR basic parameters

OPR detailed parameters

Positioning data Positioning data

Set the block start data for "major positioning control".

Block start data

Set the data for "high-level positioning control".

Condition data Set the condition data for "high-level positioning control".

Memo data

Set the condition judgment values for the condition

data used in "high-level positioning control".

to

)

Pr.1 )

Pr.57

to

)

Pr.1

)

Pr.42

to

)

Pr.80

)

Pr.84

OPR

parameters

to

)

Pr.43

)

Pr.57

to

)

Da.1 )

Da.10

to

)

Da.11

)

Da.19

to

)

Da.15

)

Da.19

to

)

Da.11

)

Da.14

Block start data

Servo parameters (Basic setting)

Servo parameters (Gain filter setting)

Set the data that is determined

by the specification of the servo

being used.

Servo

parameters

to

)

Pr.100

)

Pr.204

Servo parameters (Expansion setting)

Servo parameters (Input/output setting)

Set the values required for

carrying out OPR control.

The data is set with the PLC program or peripheral device.

In this chapter, the method using the peripheral device will be explained.

(Refer to "Point" on the next page.)

The basic parameters 1, detailed parameters 1, OPR parameters, and "

Pr.83

Speed control 10 x multiplier setting for degree axis" become valid when the PLC

READY signal [Y0] turns from OFF to ON.

The basic parameters 2, detailed parameters 2 (Note that this excludes "

Pr.83

Speed control 10 x multiplier setting for degree axis".) become valid immediately

when they are written to the buffer memory, regardless of the state of the PLC

READY signal [Y0].