5 - 50

MELSEC-Q

5 DATA USED FOR POSITIONING CONTROL

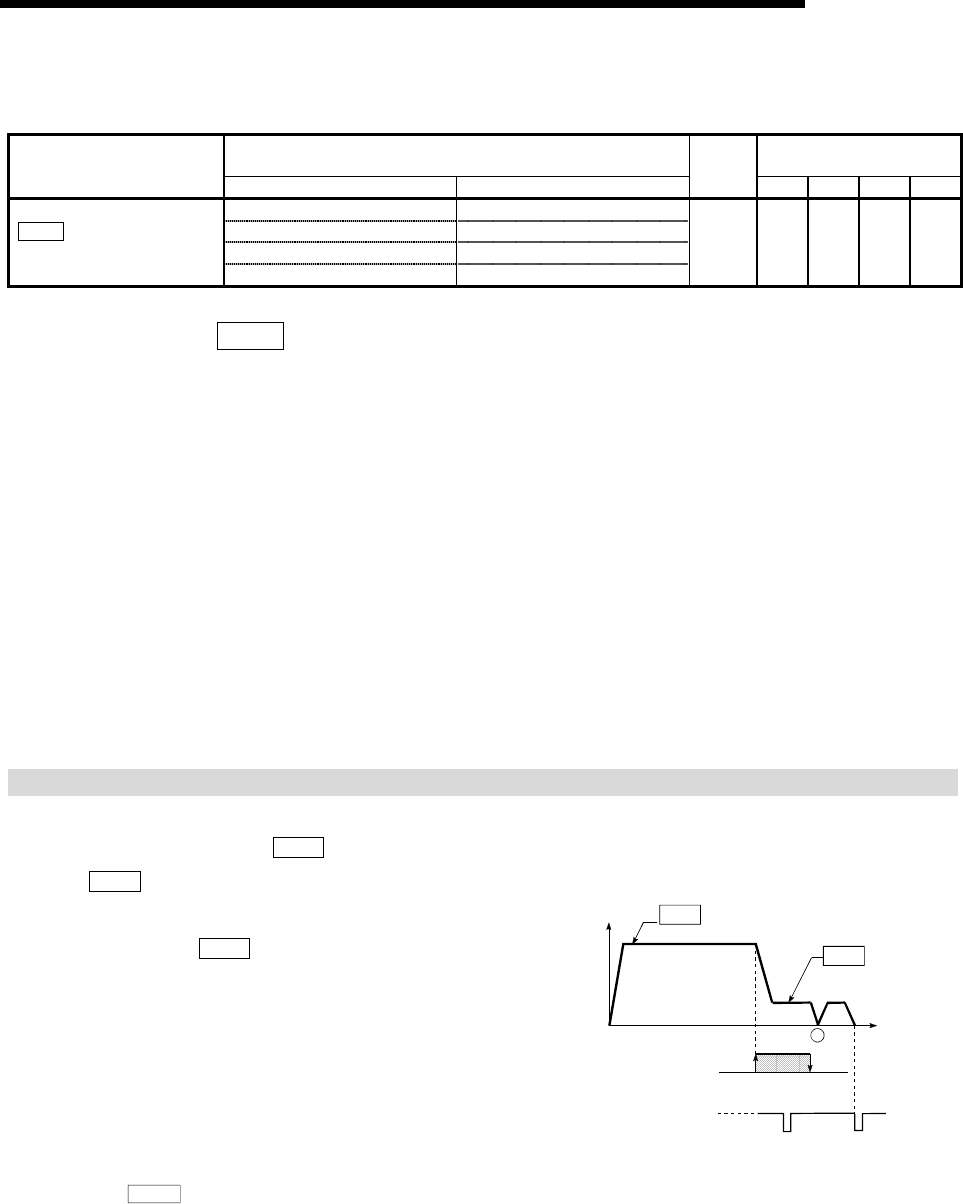

5.2.5 OPR basic parameters

Setting value, setting range

Setting value buffer memory

address

Item

Value set with peripheral device Value set with PLC program

Default

value

Axis 1 Axis 2 Axis 3 Axis 4

0 : Near-point dog method 0

4 : Count method 1) 4

5 : Count method 2) 5

Pr.43

OPR method

6 : Data set method 6

0 70 220 370 520

Pr.43

OPR method

Set the "OPR method" for carrying out machine OPR.

0 : Near-point dog method ........ After decelerating at the near-point dog ON, stop

at the zero signal and complete the machine

OPR.

4 : Count method 1) .................. After decelerating at the near-point dog ON, move

the designated distance, and complete the

machine OPR with the zero signal.

5 : Count method 2) .................. After decelerating at the near-point dog ON, move

the designated distance, and complete the

machine OPR.

6 : Data set method................... The position where the machine OPR has been

made will be the OP.

Note) Refer to Section 8.2.2 "Machine OPR method" for details on the OPR

methods.

OPR method

0 : Near-point dog method

(1) Start machine OPR.

(Start movement at the "

Pr.46

OPR speed" in the

"

Pr.44

OPR direction".)

(2) Detect the near-point dog ON, and start deceleration.

(3) Decelerate to "

Pr.47

Creep speed", and move with the

creep speed.

(At this time, the near-point dog must be ON. If the near-

point dog is OFF, the axis will decelerate to a stop.)

(4) At the first zero signal after the near-point dog turned OFF,

machine OPR is completed.

Note) After the home position return (OPR) has been

started, the zero point of the encoder must be passed

at least once before point A is reached.

However, if selecting "1: It is not necessary to pass

through the Z phase after the power on." with "

Pr.180

Function selection C-4", it is possible to

carried out the home position return (OPR).

A

t

V

ON

(1)

(2)

(3)

(4)

Near-point dog OFF

Zero signal

Pr.47

Creep speed

OPR speed

Pr.46