11 - 7

MELSEC-Q

11 MANUAL CONTROL

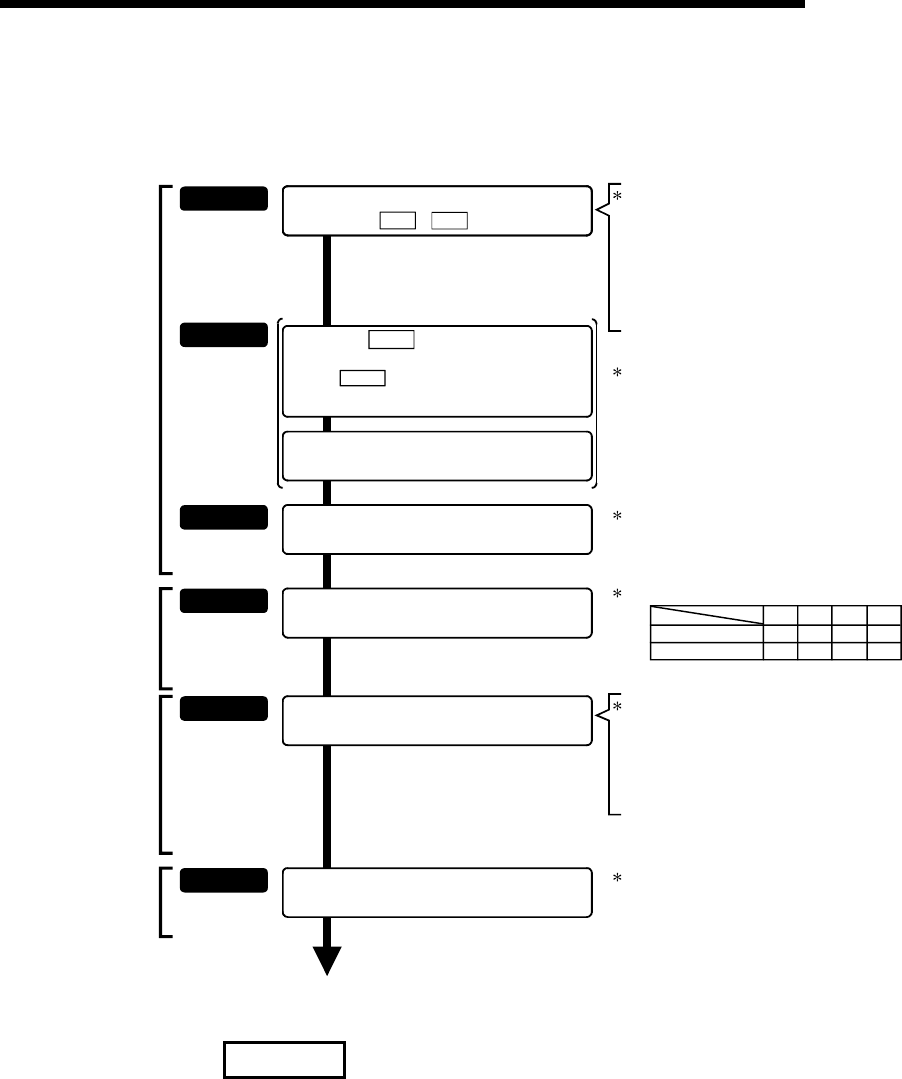

11.2.2 JOG operation execution procedure

The JOG operation is carried out by the following procedure.

STEP 1

Preparation

Refer to Chapter 5

and Section 11.2.3.

End of control

Set the positioning parameters

STEP 2

Refer to Section

11.2.4.

Set the

"

Cd. 17 JOG speed

"

.

STEP 3

Write the PLC program created in STEP 1 and

STEP 2 to the PLC CPU using GX Developer.

Turn ON the JOG start signal.

STEP 4

One of the following two methods can be used.

<Method 1>

Monitor using GX Configurator-QP.

<Method 2>

Monitor using GX Developer.

One of the following two methods can be used.

<Method 1>

Directly set (write) the parameters in the QD75MH using GX

Configurator-QP.

<Method 2>

Set (write) the parameters from the PLC CPU to the QD75MH

using the PLC program (TO command).

STEP 5

Create a PLC program in which the "JOG start

signal" is turned ON by a JOG operation start command.

Using GX Developer, set the control data and create a

PLC program for executing the JOG operation.

(Set the control data in the QD75MH buffer memory using the

TO command.)

Write the PLC program to the PLC CPU.

Turn ON the JOG start signal of the axis to be started.

Monitoring of the

J

OG operation

Stop the JOG operation when the JOG start signal is turned

OFF using the PLC program in STEP 2.

STEP 6

Turn OFF the JOG operation start signal that is ON.

Monitor the JOG operation status.

Forward run JOG start signal

Reverse run JOG start signal

Axis 1

Y8

Y9

YA

YB

YC

YD

Refer to Chapter 6.

Axis 3

Axis 2

JOG operation

start

JOG operation

stop

to

)

Pr.1

)

Pr.39

(Control data setting)

YE

YF

Axis 4

Set a "0" in " Cd. 16 Inching movement

amount".

REMARK

•

Mechanical elements such as limit switches are considered as already installed.

•

Positioning parameter settings work in common for all control using the QD75MH.