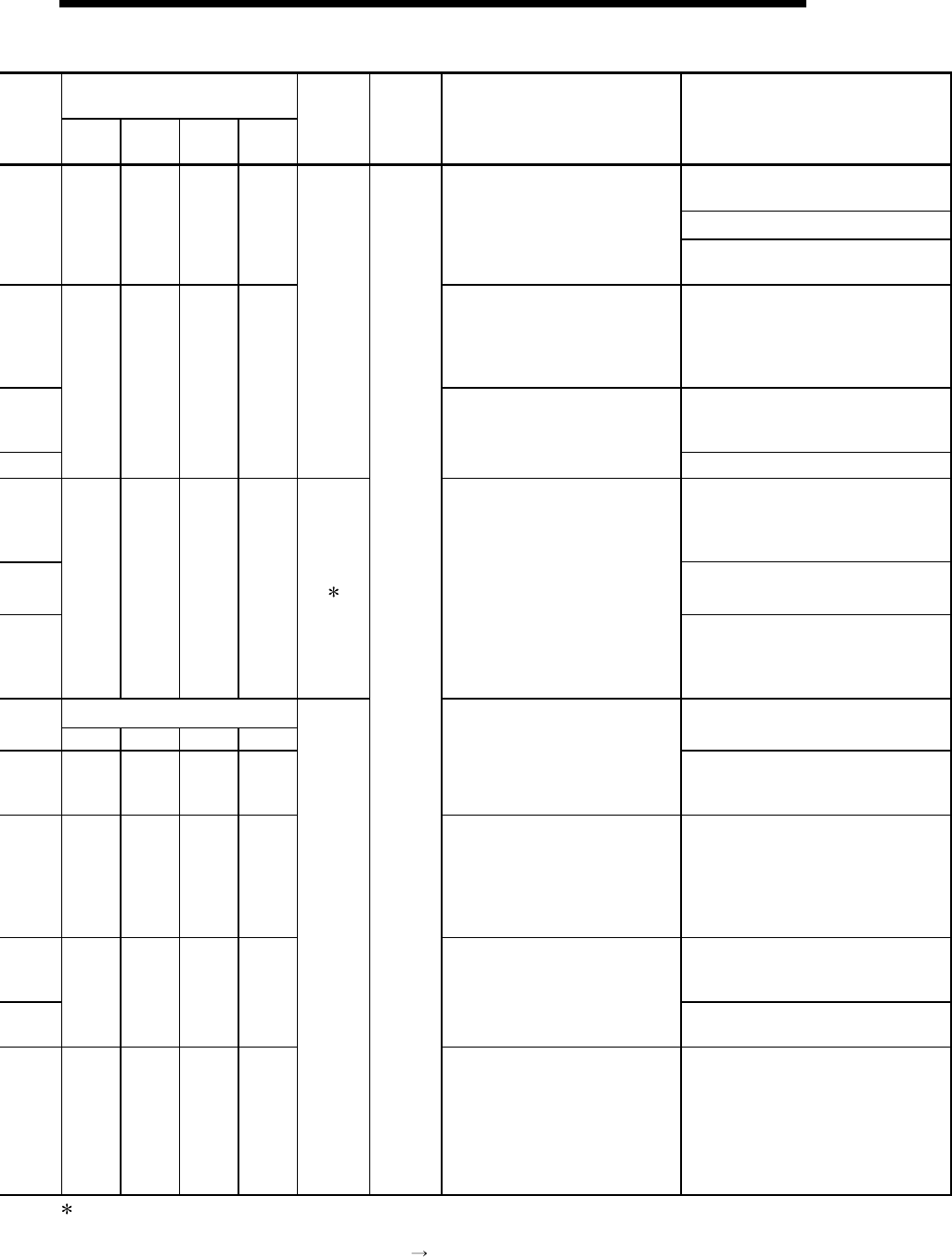

15 - 39

MELSEC-Q

15 TROUBLESHOOTING

Related buffer memory address

Axis 1 Axis 2 Axis 3 Axis 4

Error

check

timing

Error

process-

ing

Check point Corrective action

Connect correctly.

Change the servomotor.

— — — —

Repair or change the cable.

Servo amplifier error (2024)

occurs if the servo is switched

on after disconnecting the U, V,

W power cables from the servo

amplifier.

Connect correctly.

Change the cable.

— — — —

Always

Change the servo amplifier.

After leaving the alarm occurring for

few minutes, switch power off, then

on again.

Always make OPR setting again.

Change the battery.

Always make OPR setting again.

— — — —

After leaving the alarm occurring for

few minutes, switch power off, then

on again.

Always make OPR setting again.

Regenerative brake option

30102 30302 30502 30702

Set correctly.

— — — —

Connect correctly

— — — —

Call the status display and

check the regenerative load

ratio.

• Reduce the frequency of

positioning.

• Use the regenerative brake option

of larger capacity.

• Reduce the load.

Review power supply.

— — — —

Change servo amplifier or

regenerative brake option.

— — — —

Always

Imme-

diate

stop

• The regenerative brake option

has overheated abnormally.

• Servo amplifier error (2030)

occurs even after removal of

the built-in regenerative brake

resistor or regenerative brake

option.

Change the servo amplifier.

:

The error check timing is shown below.

• When servo amplifier is power ON.

• When the QD75MH detects the rising edge (OFF

ON) of the PLC READY signal [Y0].

• When servo amplifier is reset.

• When the QD75MH is power ON.