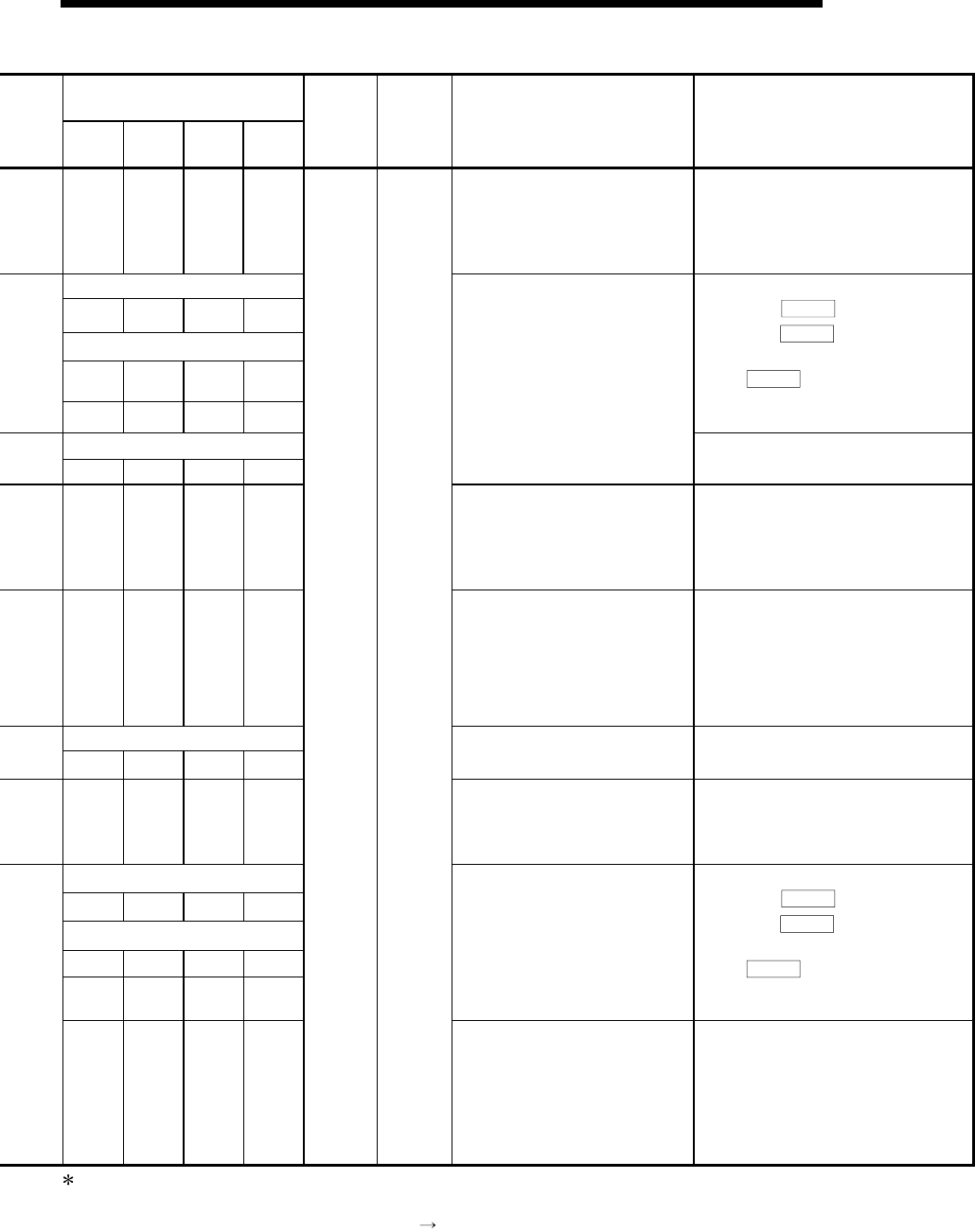

15 - 47

MELSEC-Q

15 TROUBLESHOOTING

Related buffer memory address

Axis 1 Axis 2 Axis 3 Axis 4

Error

check

timing

Error

process-

ing

Check point Corrective action

— — — —

• Reduce load.

• Review operation pattern.

• Use servomotor that provides

larger output.

Auto tuning

30108 30308 30508 30708

Auto tuning response

30109 30309 30509 30709

— — — —

• Repeat acceleration/deceleration to

execute "

Pr.108

Auto tuning".

• Change "

Pr.109

Servo response"

setting.

• Set "

Pr.108

Auto tuning" to OFF

and make gain adjustment

manually.

Input signal logic selection

31 181 331 481

• Review operation pattern.

• Install limit switches.

— — — —

Connect correctly.

— — — —

When the servomotor shaft is

rotated with the servo off, the

cumulative feedback pulses

should vary in proportion to the

rotary angle. If the indication

skips or returns midway the

encoder if faulty.

Change servomotor.

Input signal logic selection

31 181 331 481

• Review operation pattern.

• Install limit switches.

— — — —

Connect correctly.

Auto tuning

30108 30308 30508 30708

Auto tuning response

30109 30309 30509 30709

— — — —

• Repeat acceleration/deceleration to

execute "

Pr.108

Auto tuning".

• Change "

Pr.109

Servo response"

setting.

• Set "

Pr.108

Auto tuning" to OFF

and make gain adjustment

manually.

— — — —

Always

Imme-

date stop

When the servomotor shaft is

rotated with the servo off,

the cumulative feedback pulses

should vary in proportion to the

rotary angle. If the indication

skips or returns midway the

encoder if faulty.

Change the servomotor.

:

The error check timing is shown below.

• When servo amplifier is power ON.

• When the QD75MH detects the rising edge (OFF

ON) of the PLC READY signal [Y0].

• When servo amplifier is reset.

• When the QD75MH is power ON.