12 - 26

MELSEC-Q

12 CONTROL SUB FUNCTIONS

[2] Control details

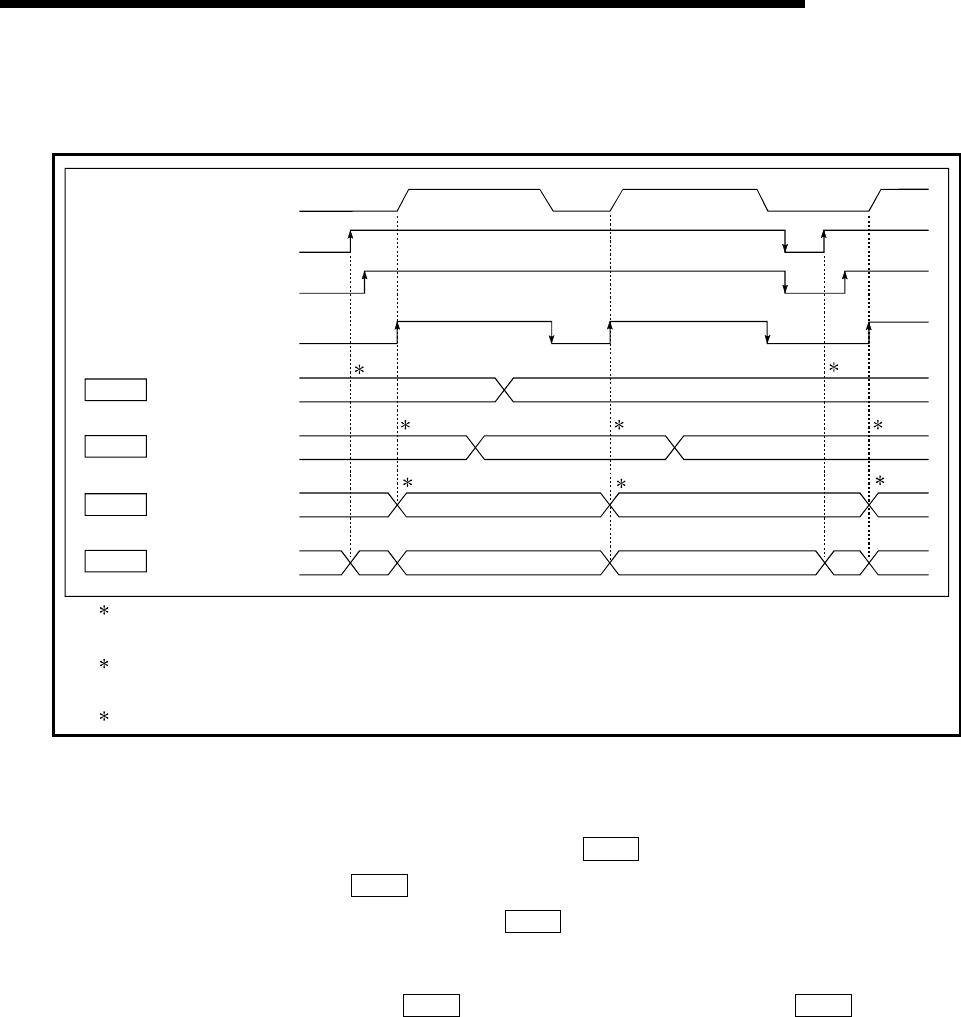

The following drawing shows the operation of the torque limit function.

300 250

100 1500

00 00

0 300 300 100 150 150

1: The torque limit setting value or torque output setting value becomes effective at the PLC READY signal (Y0) rising edge

(however, after the servo turned ON.)

If the torque output setting value is "0" or larger than the torque limit setting value, the torque limit setting value will be its value.:

2: The torque limit setting value or torque output setting value becomes effective at the start signal (Y10)rising edge.

If the torque output setting value is "0" or larger than the torque limit setting value, the torque limit setting value, the torque limit setting

value will be its value.

3: The tor

q

ue chan

g

e value is cleared to "0" at the start si

g

nal

(

Y10

)

risin

g

ed

g

e.

Each operations

PLC READY signal (Y0)

All axis servo ON (Y1)

Start signal (Y10)

Torque limit setting

value (26)

Torque output setting

value (1552)

New toruque value

(1525)

Torque limit stored

value (826)

Pr.17

Cd.101

Cd.22

Md.35

1

1

2 2 2

3

3

3

Fig. 12.12 Torque limit function operation

[3] Precautions during control

(1) When limiting the torque at the "

Pr.17

Torque limit setting value", confirm

that "

Cd.22

New torque value" is set to "0". If this parameter is set to a

value besides "0", the "

Cd.22

New torque value" will be validated, and the

torque will be limited at that value. (Refer to Section 12.5.4 "Torque change

function" for details about the "new torque value".)

(2) When the “

Pr.54

OPR torque limit value “exceeds the “

Pr.17

Torque

limit setting value”, an error occurs. (Error code: 995)

(3) When the operation is stopped by torque limiting, the droop pulse will remain

in the deviation counter. If the load torque is eliminated, operation for the

amount of droop pulses will be carried out.