12 - 7

MELSEC-Q

12 CONTROL SUB FUNCTIONS

[2] Precaution during control

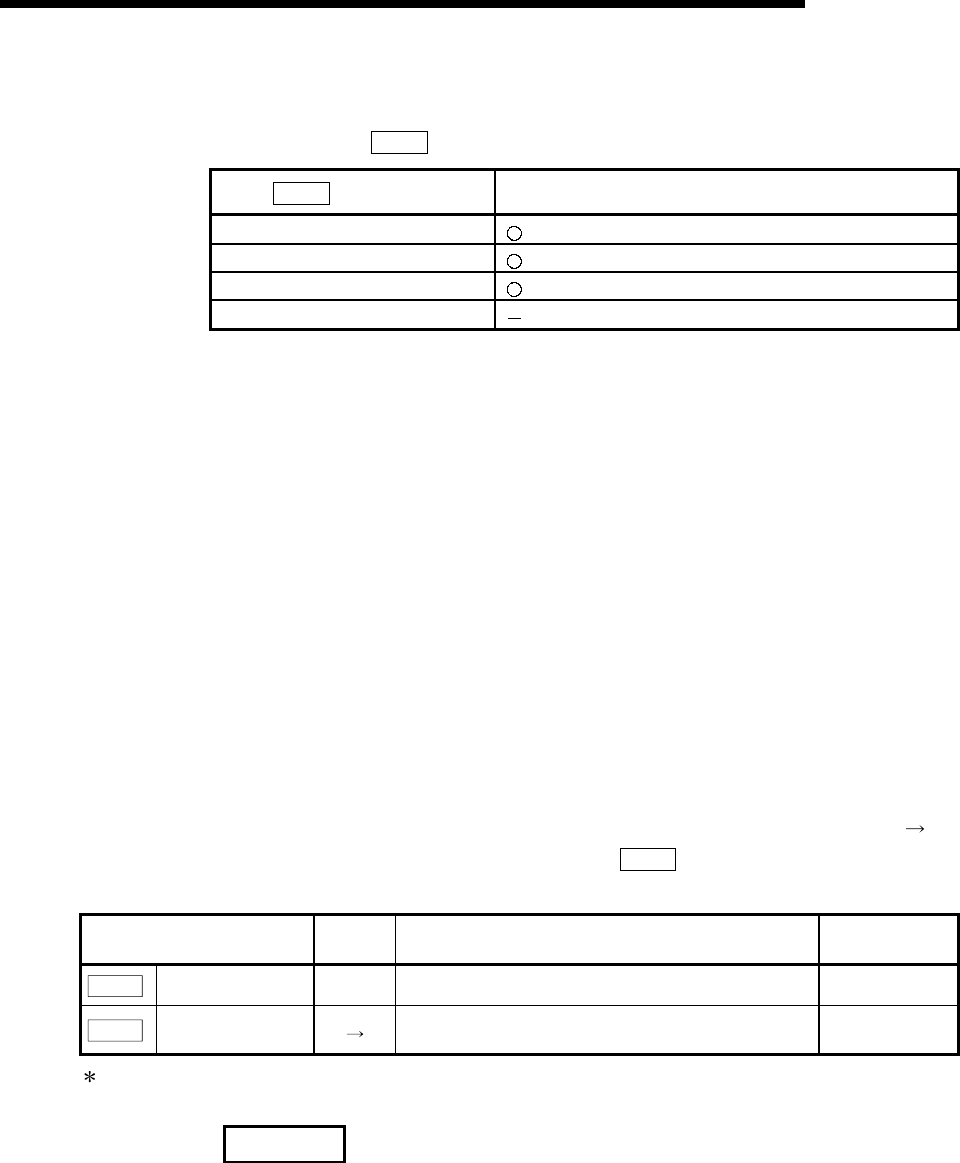

(1) The following table shows whether the OPR retry function may be executed

by the "

Pr.43

OPR method".

Pr.43

OPR method

Execution status of OPR retry function

Near-point dog method

: Execution possible

Count method 1)

: Execution possible

Count method 2)

: Execution possible

Data set method

:

(2) Always establish upper/lower limit switches at the upper/lower limit positions

of the machine, and connect an QD75MH module. If the OPR retry function

is used without hardware stroke limit switches, the motor will continue

rotation until a hardware stroke limit signal is detected.

(3) Always wire QD75MH upper/lower limit switches even when the OPR

function is invalidated. Control cannot be carried out with the QD75MH

unless the wiring is carried out.

(4) Do not carry out settings so that the servo amplifier power turns OFF by the

upper/lower limit switches connected to the QD75MH. If the servo amplifier

power is turned OFF, the OPR retry cannot be carried out.

(5) The operation decelerates upon detection of the hardware limit signal, and

the movement starts in the opposite direction. In this case, however, an

error (104, 105) is not produced.

[3] Setting the OPR retry function

To use the "OPR retry function", set the required details in the parameters shown

in the following table, and write them to the QD75MH.

When the parameters are set, the OPR retry function will be added to the

machine OPR control. The set details are validated at the rising edge (OFF

ON) of the PLC READY signal (Y0). Set "

Pr.57

Dwell time during OPR retry"

according to the user's requirements.

Setting item

Setting

value

Setting details

Factory-set

initial value

Pr.48

OPR retry 1 Set "1: Carry out OPR retry by limit switch". 0

Pr.57

Dwell time during

OPR retry

Set the deceleration stop time during OPR retry.

(Random value between 0 and 65535 (ms))

0

Refer to Section 5.2 "List of parameters" for setting details.

REMARK

•

Parameters are set for each axis.

•

It is recommended that the parameters be set whenever possible with GX

Configurator-QP. Execution by PLC program uses many PLC programs and

devices. The execution becomes complicated, and the scan times will increase.