1 - 7

MELSEC-Q

1 PRODUCT OUTLINE

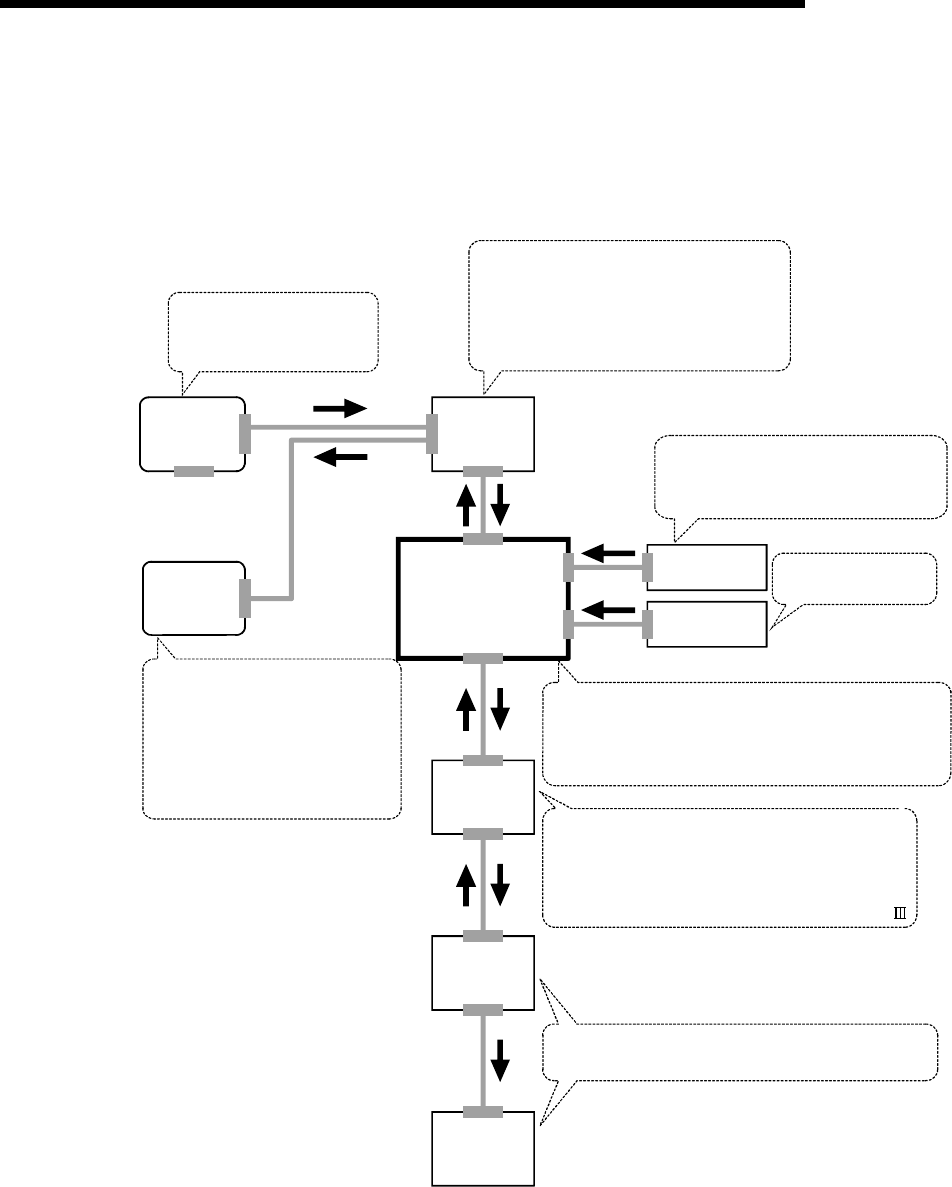

1.1.3 Mechanism of positioning control

In the positioning system using the QD75MH, various software and devices are used

for the following roles. The QD75MH realizes complicated positioning control when it

reads in various signals, parameters and data and is controlled with the PLC CPU.

Workpiece

Creates control order and

conditions as a sequence

program.

Stores the created program.

The QD75MH outputs the start signal and

stop signal following the stored program.

QD75MH errors, etc., are detected.

GX Developer

PLC CPU

Outputs signals such as the start

signal, forced stop input signal, stop

signal, limit signal and control

changeover signal to the QD75MH.

GX

Configurator

-QP

QD75MH positioning

module

External signal

Manual pulse

generator

Issues commands by

transmitting pulses.

Sets the parameters and

positioning data for control.

Outputs the start command for

JOG operation, etc., during test

operation with the test mode.

Monitors the positioning operation.

Servo

amplifier

Stores the parameter and data.

Outputs datas to the servo according to the

instructions from the PLC CPU, GX Configurator-QP,

external signals and manual pulse generator.

Receives positioning commands and control

commands from QD75MH, and drives the motor.

Outputs the positioning data of the motor

data and etc., and external input signal of the

servo amplifier to the QD75MH by the SSCNET .

Motor

Carries out the actual work according to commands

from the servo.

(Note): For QD75MH1, 2 and 4, use SW2D5C-QD75P (Version 2.21X) or later of the GX Configurator.