5 - 95

MELSEC-Q

5 DATA USED FOR POSITIONING CONTROL

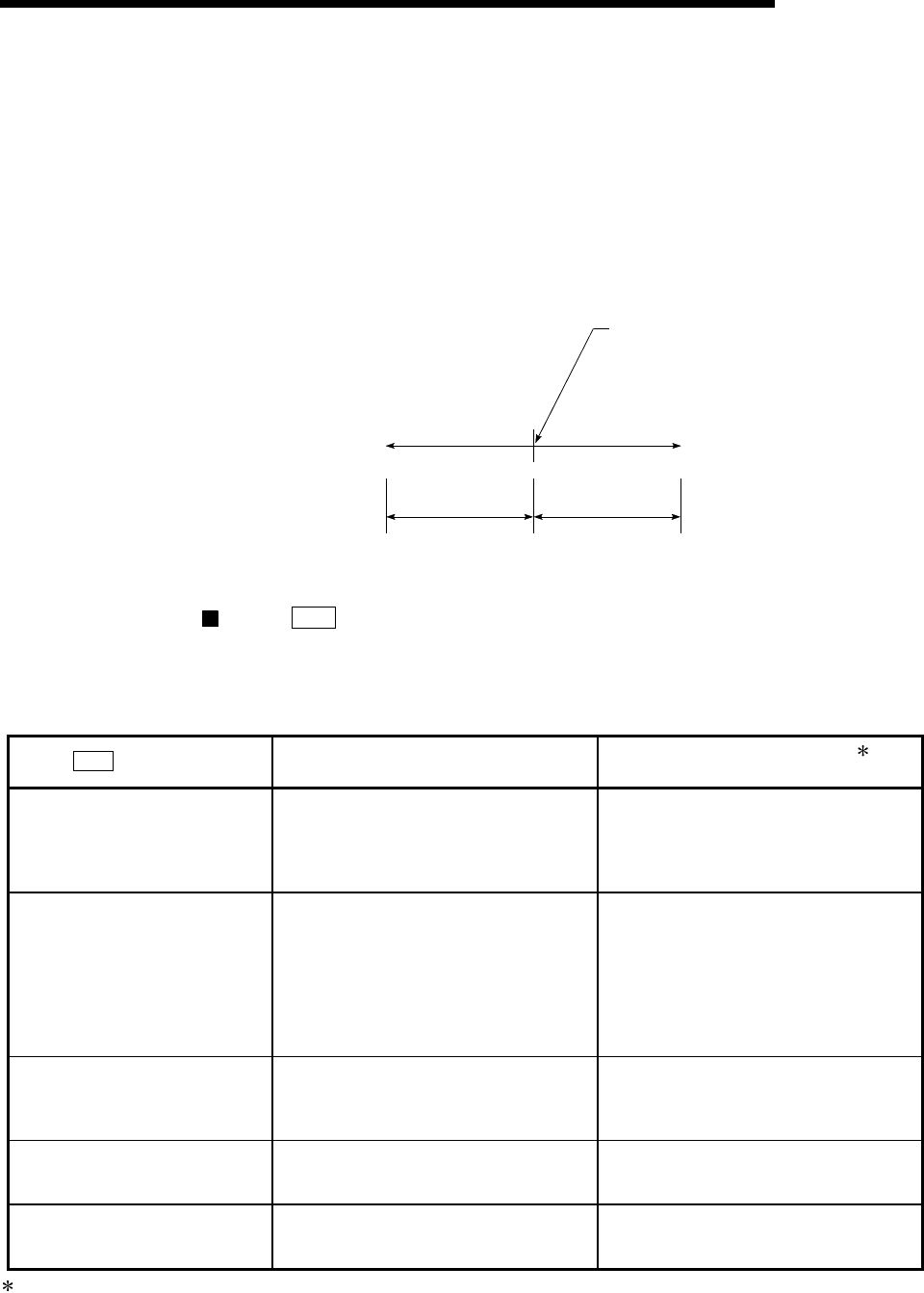

(2) Incremental (INC) system, fixed-feed 1, fixed-feed 2, fixed-feed 3,

fixed-feed 4

•

The setting value (movement amount) for the INC system is set as a

movement amount with sign.

When movement amount is positive: Moves in the positive direction (address

increment direction)

When movement amount is negative: Moves in the negative direction (address

decrement direction)

Stop position

(positioning start position)

(Movement amount)

-30000

(Movement amount)

30000

Moves in

negative direction

Moves in

positive direction

[Table 1]

When "

Pr.1

Unit Setting" is "mm"

The table below lists the control systems that require the setting of the positioning

address or movement amount and the associated setting ranges.

(With any control system excluded from the table below, neither the positioning

address nor the movement amount needs to be set.)

Da.2

setting value

Value set with peripheral device

(

µ

m)

Value set with PLC program 1

(

×

10

-1

µ

m)

ABS Linear 1 : 01

H

ABS Linear 2 : 0AH

ABS Linear 3 : 15

H

ABS Linear 4 : 1AH

Current value changing : 81H

◊

Set the address

-214748364.8 to 214748364.7

◊

Set the address

-2147483648 to 2147483647

INC Linear 1 : 02

H

INC Linear 2 : 0B

H

INC Linear 3 : 16H

INC Linear 4 : 1BH

Fixed-feed 1 : 03H

Fixed-feed 2 : 0C

H

Fixed-feed 3 : 17H

Fixed-feed 4 : 1CH

◊

Set the movement amount

-214748364.8 to 214748364.7

◊

Set the movement amount

-2147483648 to 2147483647

Forward run speed/position : 06

H

Reverse run speed/position : 07H

Forward run position/speed : 08H

Reverse run position/speed : 09

H

◊

Set the movement amount

0 to 214748364.7

◊

Set the movement amount

0 to 2147483647

ABS circular sub : 0D

H

ABS circular right : 0F

H

ABS circular left : 10H

◊

Set the address

-214748364.8 to 214748364.7

◊

Set the address

-2147483648 to 2147483647

INC circular sub : 0E

H

INC circular right : 11H

INC circular left : 12

H

◊

Set the movement amount

-214748364.8 to 214748364.7

◊

Set the movement amount

-2147483648 to 2147483647

1: Set an integer because the PLC program cannot handle fractions.

(The value will be converted properly within the system.)