5 - 24

MELSEC-Q

5 DATA USED FOR POSITIONING CONTROL

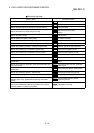

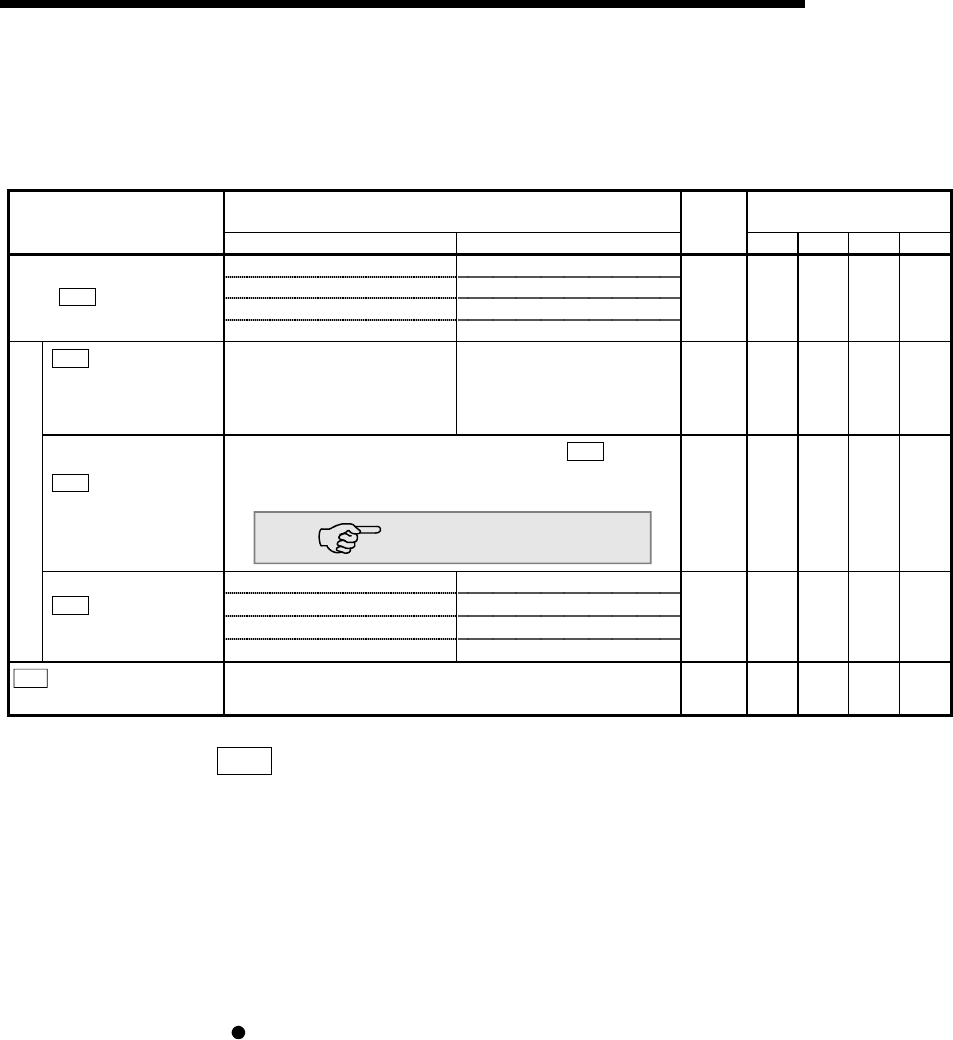

5.2 List of parameters

5.2.1 Basic parameters 1

Setting value, setting range

Setting value buffer memory

address

Item

Value set with peripheral device Value set with PLC program

Default

value

Axis 1 Axis 2 Axis 3 Axis 4

0 : mm 0

1 : inch 1

2 : degree 2

Pr.1

Unit setting

3 : PLS 3

3 0 150 300 450

Pr.2

No. of pulses per

rotation (AP)

(Unit : PLS)

1 to 200000000 1 to 200000000 20000

2

3

152

153

302

303

452

453

Pr.3

Movement amount per

rotation (AL)

The setting value range differs according to the "

Pr.1

Unit

setting".

Here, the value within the [Table 1] range is set.

[Table 1] on right page

20000

4

5

154

155

304

305

454

455

1 : 1 times 1

10 : 10 times 10

100 : 100 times 100

Movement amount per pulse

Pr.4

Unit magnification (AM)

1000 : 1000 times 1000

1 1 151 301 451

Pr.7

Bias speed at start

Not used 0

6

7

156

157

306

307

456

457

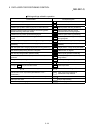

Pr.1

Unit setting

Set the unit used for defining positioning operations. Choose from the following

units depending on the type of the control target: mm, inch, degree, or PLS.

Different units can be defined for different axes (axis 1 to 4).

(Example) Different units (mm, inch, degree, and PLS) are applicable to different

systems:

mm or inch ....X-Y table, conveyor (Select mm or inch depending on the

machine specifications.)

degree ...........Rotating body (360 degrees/rotation)

PLS................X-Y table, conveyor

When you change the unit, note that the values of other parameters and data

will not be changed automatically.

After changing the unit, check if the parameter and data values are within the

allowable range.

Set "degree" to exercise speed-position switching control (ABS mode).