12 - 41

MELSEC-Q

12 CONTROL SUB FUNCTIONS

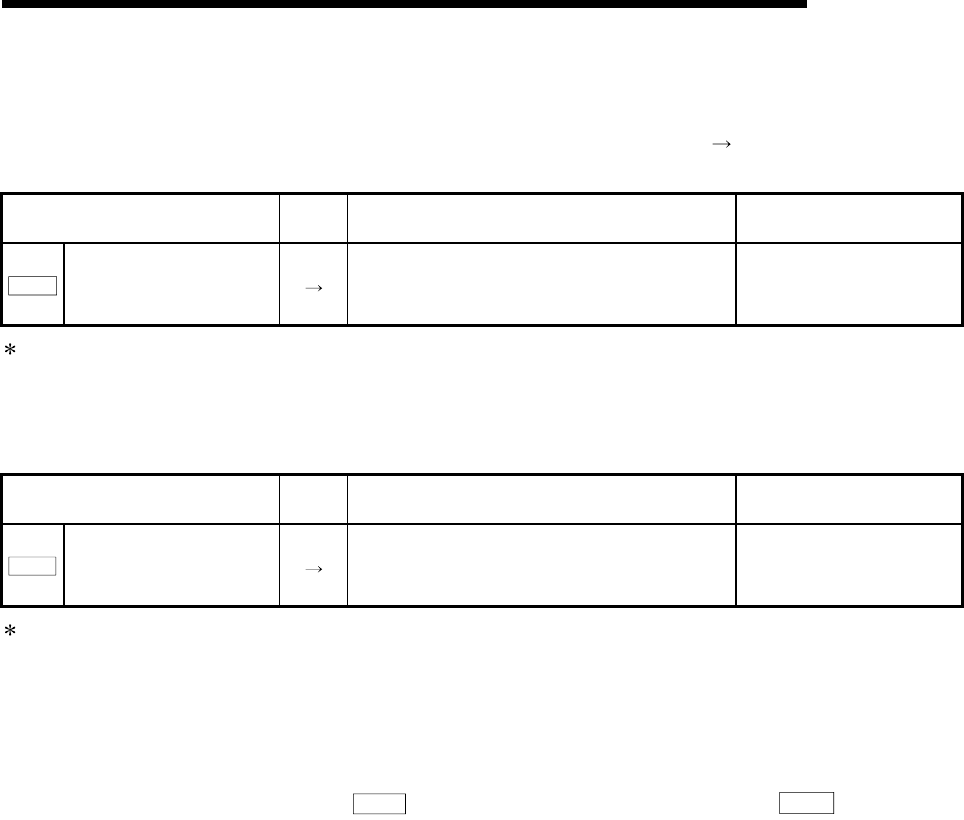

[3] Setting the forced stop

To use the "Forced stop function", set the following data using a PLC program.

The set details are validated at the rising edge (OFF

ON) of the PLC READY

signal (Y0).

Setting item

Setting

value

Setting details Buffer memory address

Pr.82

Forced stop valid/ invalid

selection

Set the forced stop function.

0 : Valid (Forced stop is used)

1 : Invalid (Forced stop is not used)

35

Refer to Section 5.2.3 "Detailed parameters 1" for details on the setting details.

[4] How to check the forced stop

To use the states (ON/OFF) of forced stop input, set the parameters shown in the

following table.

Setting item

Setting

value

Setting details Buffer memory address

Md.50

Forced stop input

Stores the states (ON/OFF) of forced stop input.

0 : Forced stop input ON (Forced stop)

1 : Forced stop input OFF (Forced stop release)

1431

Refer to Section 5.6.1 "System monitor data" for details on the setting details.

[5] Precautions during control

(1) After the "Forced stop input" is released, the servo ON/OFF is valid for the

status of all axis servo ON (Y1).

(2) If the setting is other than 0 and 1, "Forced stop valid/invalid setting error"

(error code: 937) occurs.

(3) The "

Md.50

Forced stop input" is stored "1" by setting "

Pr.82

Forced stop

valid/invalid selection" to invalid.

(4) When the "Forced stop input" is turned ON during operation, the "Servo

READY signal OFF during operation error (error code: 102)" will not occur.